Polyimide/carbon nano-tube X-ray window thin film and preparation method thereof

A technology of carbon nanotubes and window films, which is applied in the field of material testing of X-ray applications, can solve problems such as difficult processing, poisonous beryllium windows, and use, and achieve the effects of simple processing methods, improved mechanical properties, and high transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

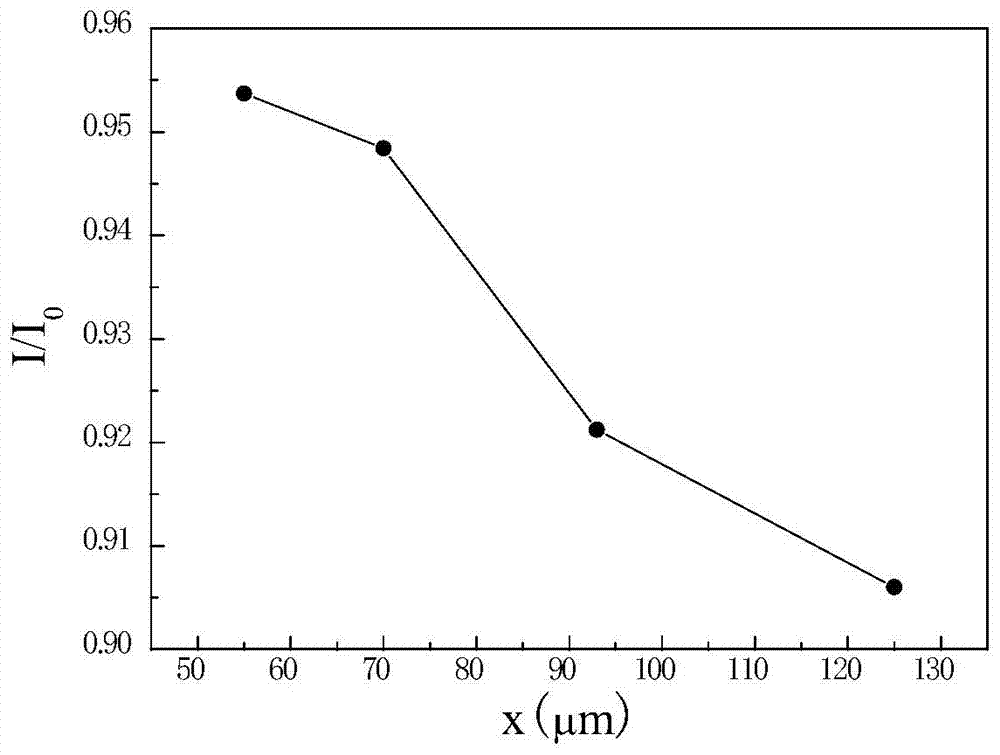

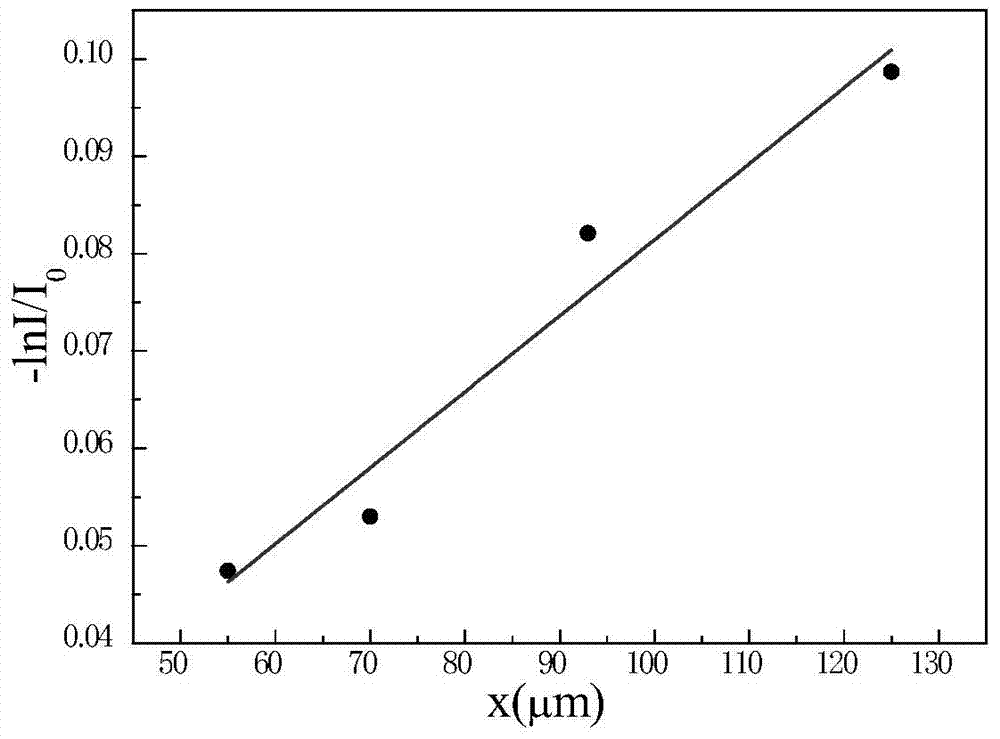

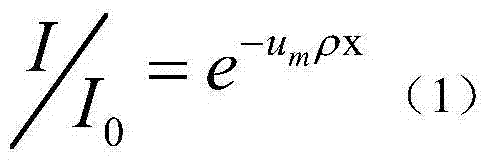

[0012] Specific embodiment 1: This embodiment is a polyimide / carbon nanotube X-ray window film, which is prepared from modified carbon nanotubes, diamine monomers, dianhydride monomers and organic solvents. The mass ratio of modified carbon nanotube and diamine monomer is 0.021:1; the molar ratio of described dianhydride monomer and diamine monomer is 1:1; the volume of described organic solvent and diamine monomer The mass ratio is 13.3mL:1g.

[0013] As a special engineering material, polyimide film is widely used in aviation, aerospace, microelectronics, nanometer, liquid crystal, separation membrane, laser and other fields. Because of its outstanding features in performance and synthesis, its huge application prospects, whether as structural materials or functional materials, have been fully recognized. Thermosetting polyimide has excellent thermal and mechanical properties. The initial thermal decomposition temperature is about 500 ° C. It can withstand extremely low tem...

specific Embodiment approach 2

[0017] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the modified carbon nanotubes are prepared according to the following method:

[0018] Method 1: Add concentrated hydrochloric acid to carbon nanotubes, ultrasonically treat for 8 hours, separate solid and liquid with a centrifuge, centrifuge once, rinse with distilled water, rinse until the pH value of the eluate is neutral, and store in a vacuum oven at 80°C Dry for 2 hours to obtain modified carbon nanotubes; the volume ratio of the carbon nanotubes to concentrated hydrochloric acid is 0.2g:200mL; the carbon nanotubes are single-walled carbon nanotubes or multi-walled carbon nanotubes;

[0019] Method 2: Add mixed acid to the carbon nanotubes, sonicate at room temperature for 8 hours, add distilled water to dilute, then let it stand for 12 hours, pour off the supernatant, filter it with a polytetrafluoroethylene membrane with a pore size of 0.22 μm, and then wash it with de...

specific Embodiment approach 3

[0021] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is: the diamine monomer is diaminodiphenyl ether, p-phenylenediamine, 4,4'-diaminodiphenyl sulfone Or 4,4 diaminodiphenylmethane. Others are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com