Cladophora comprehensive utilization technology

The invention relates to a technology of Phytophthora algae and technology, which is applied in the field of comprehensive development and utilization of Phytolithiasis algae, and can solve the problems of high toughness of algae body, thick algae cell wall, and difficulty in decomposition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

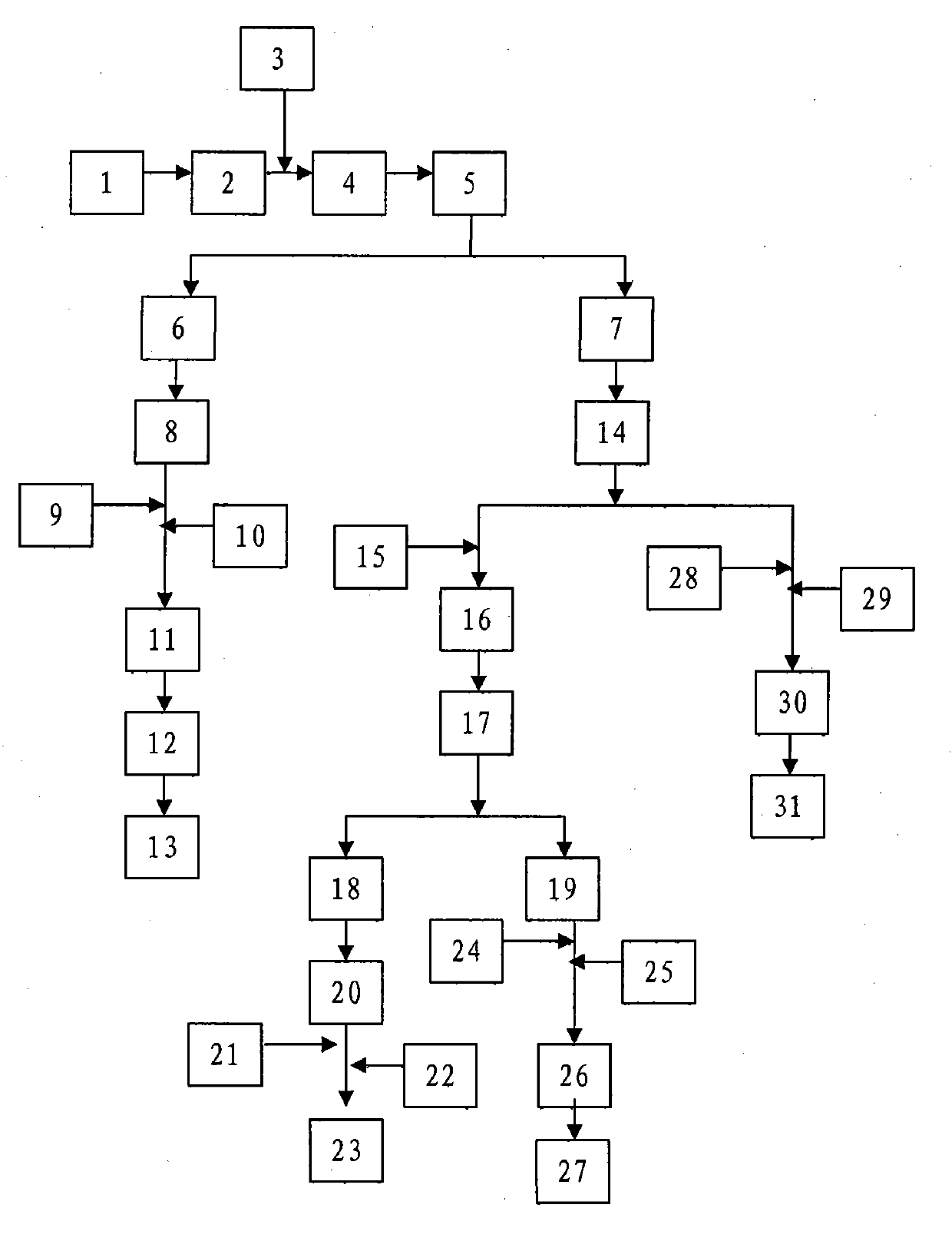

[0016] Cladoella is harvested and dried (1), then mechanically pulverized, and passed through a 10-100 mesh sieve (2). Add 1-5% dilute sulfuric acid (3) according to the solid-to-liquid ratio of 1:5-1:20, heat at 50-100°C for 10-90min (4), filter and separate (5), and obtain the treatment liquid (6) and Cladophora Processed residue (7).

[0017] Adjust the pH of the treatment solution (6) to 3.5-7.0 (8), add an appropriate amount of ammonium sulfate, potassium dihydrogen phosphate, magnesium sulfate, calcium chloride, etc. (9), insert the activated yeast (10), and inoculate the amount of 1- 10%, cultured at 20-35° C. for 4-20 hours (11), centrifuged (12), and separated to obtain feed yeast (13), whose protein content is higher than 45%.

[0018] Adjust the pH of the residue (7) to 4.5-5.5 (14), add 10-100 times of water, add 10-200U / g cellulase (15), and enzymatically hydrolyze at 30-60°C for 1-40h (16) , separated by filtration (17), to obtain the enzymolysis liquid (18) an...

Embodiment 2

[0022] Cladoella is harvested and dried (1), then mechanically pulverized, and passed through a 10-100 mesh sieve (2). Add 2-5% sodium hydroxide solution (3) according to the solid-to-liquid ratio of 1:5-1:30, heat at 50-100°C for 10-90min (4), and centrifuge (5) to obtain the treatment liquid (6) and bristles Residue after algae treatment (7).

[0023] Adjust the pH of the treatment solution (6) to 3.5-7.0 (8), add an appropriate amount of ammonium sulfate, potassium dihydrogen phosphate, magnesium sulfate, calcium chloride, etc. (9), insert the activated yeast (10), and inoculate the amount of 1- 20%, cultured at 20-35° C. for 4-20 hours (11), flocculated and separated (12), and after separation, feed yeast (13) was obtained, and the protein content was higher than 47%.

[0024] Adjust the pH of the residue (7) to 4.5-5.5 (14), add 10-100 times of water, add 10-100U / g cellulase (15), and enzymatically hydrolyze at 30-60°C for 1-40h (16) , separated by filtration (17), to o...

Embodiment 3

[0028] Cladoella is harvested and dried (1), then mechanically pulverized, and passed through a 10-100 mesh sieve (2). Add 2-5% sodium hydroxide solution (3) according to the solid-to-liquid ratio of 1:5-1:30, heat at 50-100°C for 10-90min (4), filter and separate (5), and obtain the treatment liquid (6) and bristles Residue after algae treatment (7).

[0029] Adjust the pH of the treatment solution (6) to 3.5-7.0 (8), add an appropriate amount of ammonium sulfate, potassium dihydrogen phosphate, magnesium sulfate, calcium chloride, etc. (9), insert the activated yeast (10), and inoculate the amount of 1- 20%, cultured at 20-35°C for 4-20h (11), centrifuged (12) to obtain feed yeast (13), the protein content of which is higher than 45%.

[0030] Adjust the pH of the residue (7) after the treatment of Cladophora to 4.5-5.5 (14), add 10-100 times the water, add 10-200U / g cellulase (28), and inoculate the mold (29) at the same time, 25- Cultivate at 35° C. for 10-24 hours (30),...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com