Functionalized graphene-based solar back aluminum slurry and preparation method thereof

A technology of solar energy and graphene, applied in the direction of conductive materials dispersed in non-conductive inorganic materials, cable/conductor manufacturing, electrical components, etc., can solve problems such as poor bending resistance, poor adhesion, and poor conductivity , to achieve good weather resistance, excellent printing performance and chemical resistance, good electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

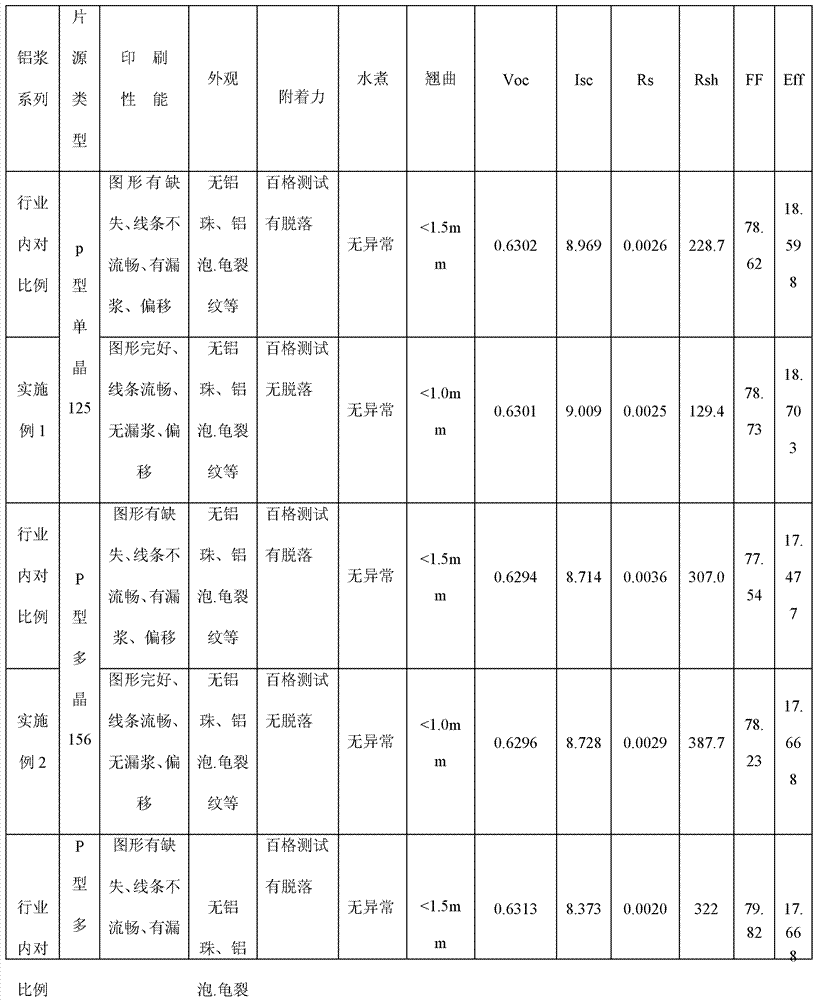

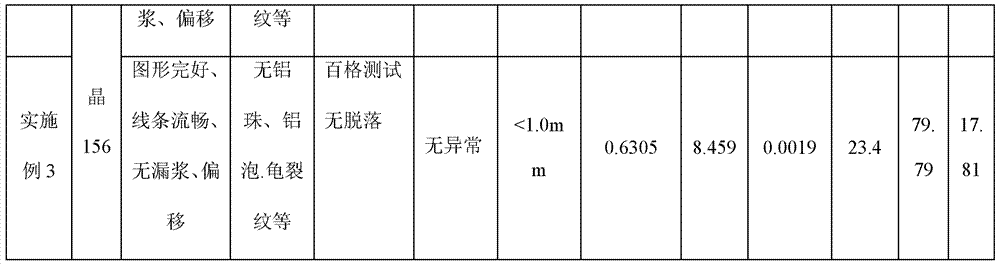

Embodiment 1

[0029] First prepare functionalized graphene dispersion liquid, its process is: Utilize A-187 coupling agent to modify graphene oxide, obtain modified graphene oxide by A-187 coupling agent and graphene oxide reaction: by mass 50 parts of modified graphene oxide were dissolved in 40 parts of a mixed solution of deionized water and absolute ethanol with a volume ratio of 1:1. After ultrasonication for 40 min, 5 parts of absolute ethanol with a concentration of 40 g / L containing a coupling agent were placed in the Add slowly under stirring, continue to react for 18 hours after the addition, and wash the obtained pasty product 3 times with absolute ethanol to remove excess coupling agent, then wash 5 times with deionized water, filter, and dry in a 60°C oven ; After modification, covalent bonds are formed between each other to significantly improve the thermal stability of the modified graphene oxide; then it is reduced, and the modified graphene oxide is placed in a ceramic cruci...

Embodiment 2

[0033] First prepare functionalized graphene dispersion liquid, its process is: Utilize A-1100 coupling agent to modify graphene oxide, obtain modified graphene oxide by A-1100 coupling agent and graphene oxide reaction: by mass 50 parts of modified graphene oxide were dissolved in 40 parts of a mixed solution of deionized water and absolute ethanol with a volume ratio of 1:1. After ultrasonication for 40 min, 5 parts of absolute ethanol with a concentration of 40 g / L containing a coupling agent were placed in the Add slowly under stirring, continue to react for 18 hours after the addition, and wash the obtained pasty product 3 times with absolute ethanol to remove excess coupling agent, then wash 5 times with deionized water, filter, and dry in a 60°C oven ; After modification, covalent bonds are formed between each other to significantly improve the thermal stability of the modified graphene oxide; then it is reduced, and the modified graphene oxide is placed in a ceramic cru...

Embodiment 3

[0037] First prepare functionalized graphene dispersion liquid, its process is: Utilize A-174 coupling agent to modify graphene oxide, obtain modified graphene oxide by A-174 coupling agent and graphene oxide reaction: by mass 50 parts of modified graphene oxide were dissolved in 40 parts of a mixed solution of deionized water and absolute ethanol with a volume ratio of 1:1. After ultrasonication for 40 min, 5 parts of absolute ethanol with a concentration of 40 g / L containing a coupling agent were placed in the Add slowly under stirring, continue to react for 18 hours after the addition, and wash the obtained pasty product 3 times with absolute ethanol to remove excess coupling agent, then wash 5 times with deionized water, filter, and dry in a 60°C oven ; After modification, covalent bonds are formed between each other to significantly improve the thermal stability of the modified graphene oxide; then it is reduced, and the modified graphene oxide is placed in a ceramic cruci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com