A kind of antibacterial composite nanofiber high-efficiency air filter material and preparation method thereof

A high-efficiency air filtration and composite nanofiber technology, which is applied in the direction of filtration separation, separation methods, chemical instruments and methods, etc., can solve the problems of low filtration efficiency, poor filtration ability and roughness of oily substances, and achieve simple preparation process and high filtration efficiency High and good protective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

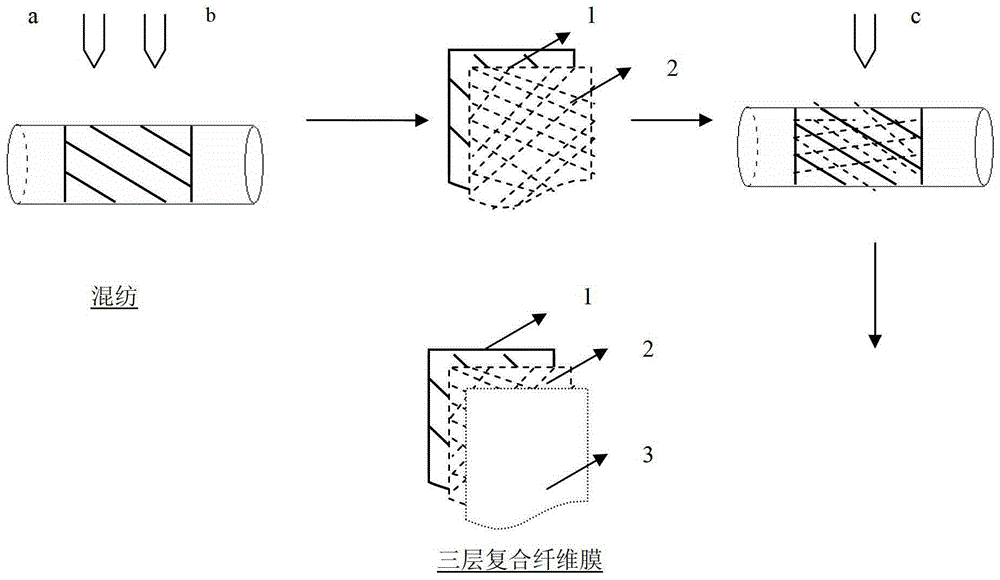

Method used

Image

Examples

Embodiment 1

[0039]A preparation method of an antibacterial composite nanofiber high-efficiency air filter material: (1) Dissolve 3 g of polyester chips in 15 ml of a mixed solvent (TFA: dichloromethane DCM at a ratio of 4:1), and stir to dissolve. (2) Add 1 part of silver nitrate to dimethylformamide DMF solvent and stir to dissolve, then add 99 parts of polyacrylonitrile chips and stir to dissolve, the mass fraction of polyacrylonitrile is 28w%; (3) Mix the two polymer solutions Add them into two syringes respectively, use a drum receiving device, control the spinning voltage to 18KV, extrusion speed to 0.001mm / s, receiving distance to 15cm, and spin interwoven fiber film with a thickness of 100μm. The diameter of the polyester electrospun fiber in the interwoven film is about 900nm, and the diameter of the silver-containing polyacrylonitrile fiber is about 300nm; (4) Dissolve 1.7g of nylon 6 slices in 15ml of formic acid, add it to the syringe, and control the spinning voltage to 20KV, ...

Embodiment 2

[0041] A preparation method of an antibacterial composite nanofiber high-efficiency air filter material: (1) Dissolve 3g of polyester chips in 15ml of a mixed solvent (TFA:DCM is 4:1), and stir to dissolve. (2) Add 1 part of silver nitrate to ethanol solvent and stir to dissolve, then add 99 parts of polyvinylpyrrolidone powder and stir to dissolve, the volume fraction of polyvinylpyrrolidone is 25%; (3) Add the two polymer solutions to two In the injector, a drum-type receiving device is used, the spinning voltage is controlled to 18KV, the extrusion speed is 0.001mm / s, and the receiving distance is 15cm, the interwoven fiber film is spun out with a thickness of 100μm. The diameter of the polyester electrospun fiber in the interwoven film is about 900nm, and the diameter of the silver-containing polyvinylpyrrolidone fiber is about 200nm; (4) Dissolve 1.7g of nylon 6 slices in 15ml of formic acid, add it to the syringe, and control the spinning voltage to 20KV. The receiving d...

Embodiment 3

[0043] A preparation method of an antibacterial composite nanofiber high-efficiency air filter material: (1) Dissolve 3g of polyester chips in 15ml of a mixed solvent (TFA:DCM is 4:1), and stir to dissolve. (2) Add 1 part of silver nitrate to the mixed solvent of dichloromethane and DMF (the volume ratio is DCM: DMF is 4:1) and stir to dissolve, then add 99 parts of polylactic acid slices and stir to dissolve, the mass fraction of polylactic acid 8w%; (3) Add the two polymer solutions into two syringes respectively, use a drum-type receiving device, control the spinning voltage to 18KV, the extrusion speed to 0.001mm / s, and the receiving distance to 15cm to spin interlaced Fibrous membrane with a thickness of 100 μm. The diameter of the polyester electrospun fiber in the interwoven film is about 900nm, and the diameter of the silver-containing polylactic acid fiber is about 400nm; (4) Dissolve 1.7g of nylon 6 slices in 15ml of formic acid, add it to the syringe, control the sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com