Preparation method of a self-assembled silver phosphate-based composite visible light catalytic material

A silver phosphate-based, catalytic material technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems of low response to visible light, limited photocatalytic activity, and low quantum efficiency, and achieve High cycle stability, good visible light absorption effect, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

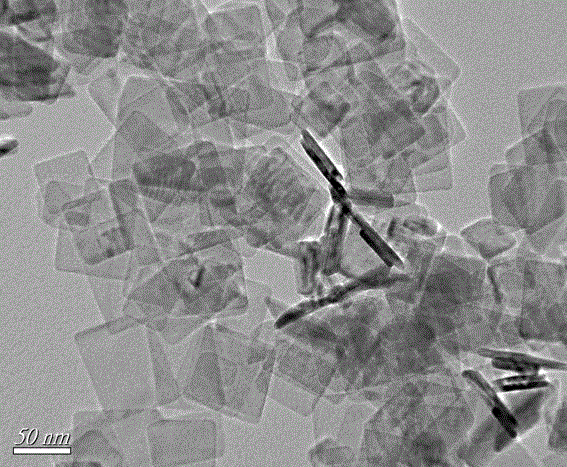

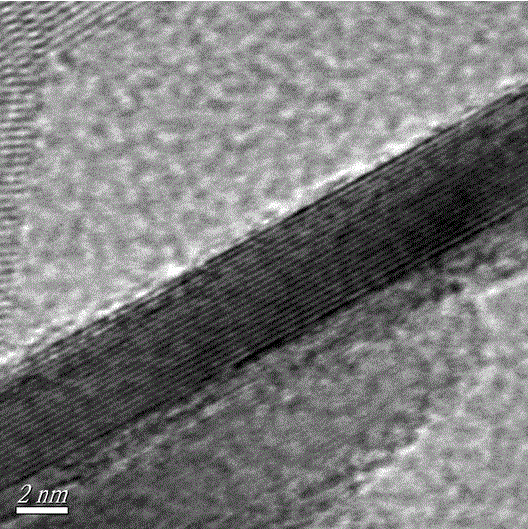

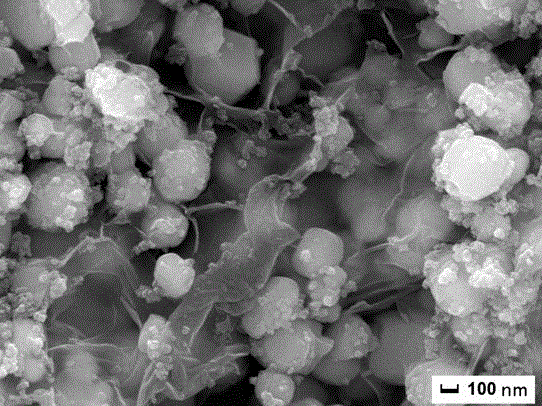

[0033] Disperse 20 mg of graphene oxide in 30 ml of deionized water and sonicate for 5 hours to obtain a graphene oxide dispersion, weigh 0.1529 g of silver nitrate and dissolve it in 20 ml of deionized water to obtain a silver nitrate solution, stir the above nitric acid with a magnetic stirrer The silver solution was added dropwise to the graphene oxide dispersion, and stirred for 12 hours to form a mixed precursor solution A. Dissolve 300 mg of titanium dioxide nanosheets in 30 ml of deionized water and ultrasonically disperse for 30 min to obtain a titanium dioxide dispersion. Add it dropwise to the above-mentioned combined precursor solution A under the condition of stirring with a mixer to obtain a mixed solution B; weigh 0.426 g of disodium hydrogen phosphate solid and dissolve it in 20 ml of deionized water to obtain a disodium hydrogen phosphate solution, stir it with a magnetic stirrer Add the prepared disodium hydrogen phosphate solution to the mixed solution B dropw...

Embodiment 2

[0035] Disperse 50 mg of graphene oxide in 30 ml of deionized water and ultrasonically obtain a graphene oxide dispersion for 5 hours, weigh 0.1529 g of silver nitrate and dissolve it in 20 ml of deionized water to obtain a silver nitrate solution, stir the above nitric acid with a magnetic stirrer The silver solution was added dropwise to the graphene oxide dispersion, and stirred for 12 hours to form a mixed precursor solution A. Dissolve 240 mg of titanium dioxide nanosheets in 30 ml of deionized water and ultrasonically disperse for 30 minutes to obtain a titanium dioxide dispersion. Add dropwise to the above-mentioned combined precursor solution A under stirring conditions to obtain a mixed solution B; weigh 0.426 g of disodium hydrogen phosphate solid and dissolve it in 20 ml of deionized water to obtain a disodium hydrogen phosphate solution, and stir it with a magnetic stirrer. The prepared disodium hydrogen phosphate solution was added dropwise to the mixed solution B,...

Embodiment 3

[0037]Disperse 100 mg of graphene oxide in 30 ml of deionized water and sonicate for 5 hours to obtain a graphene oxide dispersion, weigh 0.1529 g of silver nitrate and dissolve it in 20 ml of deionized water to obtain a silver nitrate solution, stir the above nitric acid with a magnetic stirrer The silver solution was added dropwise to the graphene oxide dispersion, and stirred for 12 hours to form a mixed precursor solution A. Dissolve 600 mg of titanium dioxide nanosheets in 30 ml of deionized water and ultrasonically disperse for 30 minutes to obtain a titanium dioxide dispersion. Add dropwise to the above-mentioned combined precursor solution A under stirring conditions to obtain a mixed solution B; weigh 0.426 g of disodium hydrogen phosphate solid and dissolve it in 20 ml of deionized water to obtain a disodium hydrogen phosphate solution, and stir it with a magnetic stirrer. The prepared disodium hydrogen phosphate solution was added dropwise to the mixed solution B, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| absorbance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com