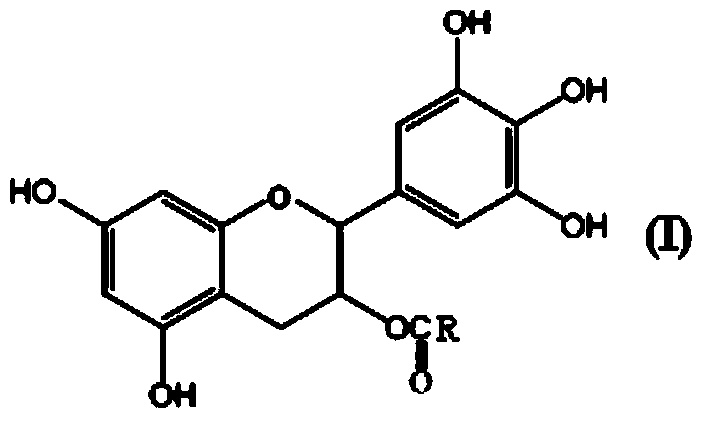

3-O-catechin higher fatty acid ester and preparation method thereof

A technology of higher fatty acids and fatty acid esters, applied in the direction of fat production, preservation of fatty substances with additives, organic chemistry, etc., can solve the problems of low bioavailability, limited application, and reduced activity, so as to improve the antioxidant effect, Good reaction selectivity and increased compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

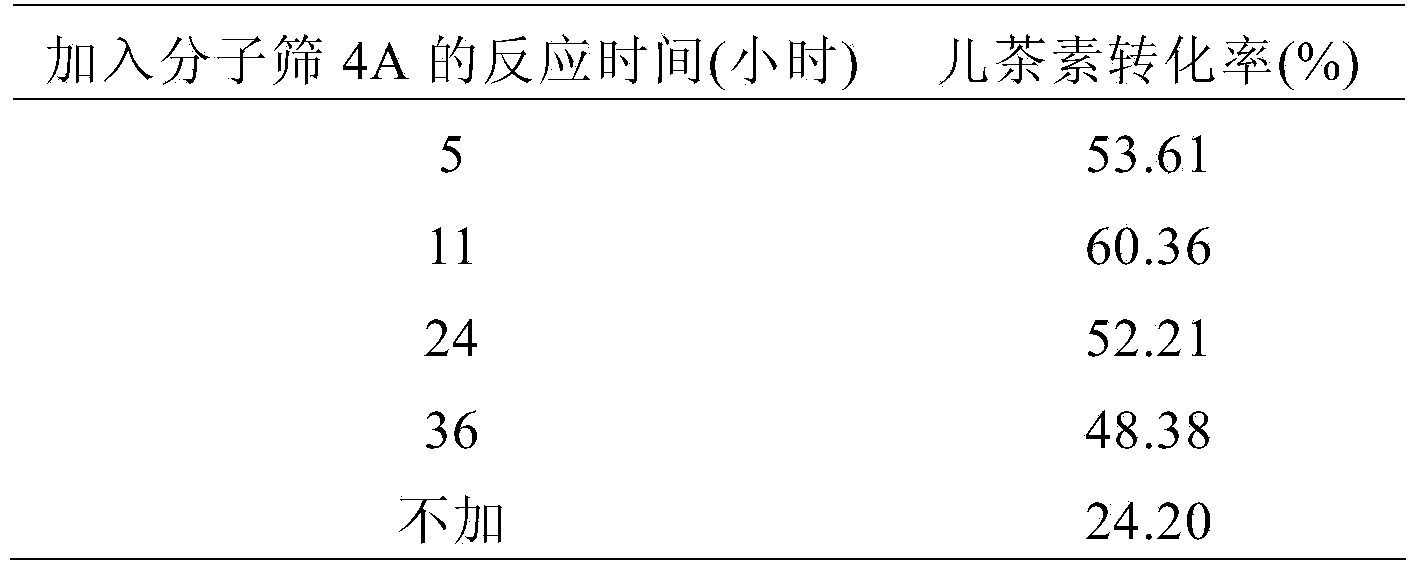

[0025] Example 1: The effect of adding molecular sieve 4A on the conversion rate of catechins at different reaction times

[0026] Take 0.15g catechin, 0.75g stearic acid, 0.605g Novozym435 lipase, add 150ml n-butanol as a solvent into a 250ml Erlenmeyer flask, put the Erlenmeyer flask into an air bath shaker, and shake the shaker at a speed of 60rpm / min, the temperature is controlled at 55-60°C, and after reacting for 5, 11, 24, and 36 hours respectively, add 22.5g of dry molecular sieve 4A, which is activated at 150°C for 24 hours before continuing the reaction. After 96 hours, the reaction was stopped. Filtrate to remove enzyme and molecular sieve; Concentrate under reduced pressure to remove solvent to obtain product, utilize thin-layer chromatography to separate and purify the reaction product, thin-layer developer is ethyl acetate: petroleum ether: ethanol: water: formic acid=15:1:1:2: 0.5. When adding molecular sieves at different reaction times, the conversion rate ...

Embodiment 2

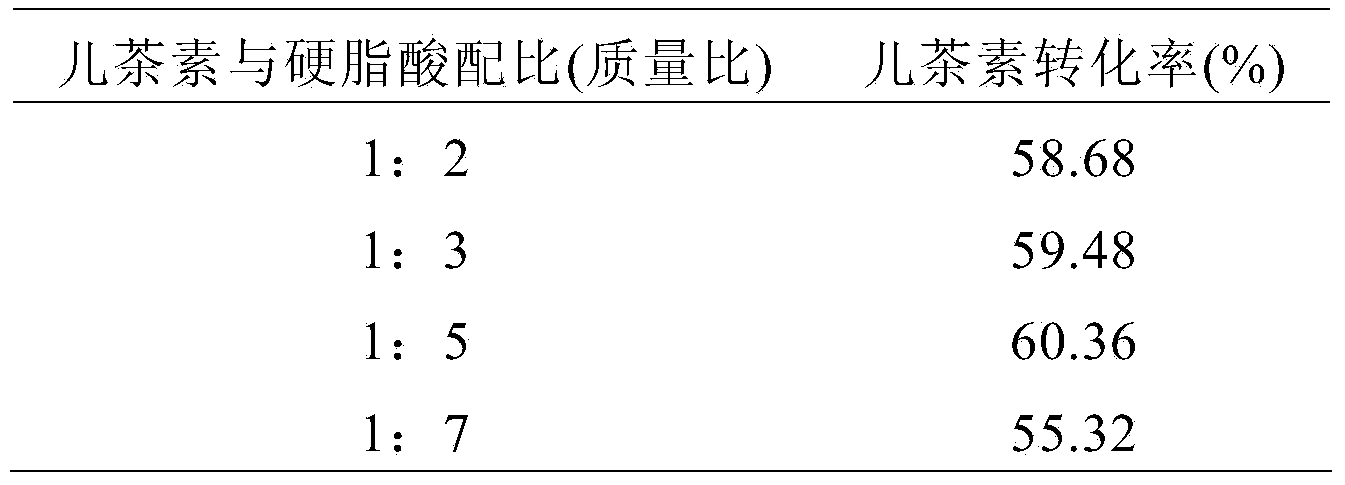

[0029] Example 2: Effects of Variations in the Ratio of Catechin and Stearic Acid on the Conversion Rate of Catechin

[0030] 0.15g catechin, 0.605g Novozym435 lipase, the solvent is 150ml n-butanol, respectively, and different amounts of stearic acid are added to a 250ml Erlenmeyer flask, and the Erlenmeyer flask is placed in an air-bath shaker. The temperature is 50rpm / min, the temperature is controlled at 55-60°C, after 11 hours of reaction, add dry molecular sieve 4A15g to continue the reaction; after 96 hours, stop the reaction; filter to remove enzyme and molecular sieve; decompress and concentrate to remove solvent to obtain the product, use The reaction product was separated and purified by thin layer chromatography. Table 2 shows the effect of the ratio of catechin and stearic acid on the conversion rate of catechin. It can be seen from Table 2 that when the mass ratio of catechin to stearic acid is 1:5, the conversion rate of catechin is higher.

[0031] Table 2 Th...

Embodiment 3

[0033] Embodiment 3: the influence of different reaction temperatures on the conversion rate of catechins

[0034] Get catechin 0.15g, stearic acid 0.75g, 0.605g enzyme, 150ml n-butanol as solvent, add in 250ml Erlenmeyer flask, put Erlenmeyer flask into air bath shaker, shaker speed is 70rpm / Add 30g of molecular sieve 4A at 11h, control the temperature at 20-60°C, finish the reaction after 96 hours, filter to remove the enzyme and molecular sieve; concentrate under reduced pressure to remove the solvent to obtain the product, and use thin-layer chromatography to separate and purify the reaction product. The effects of different reaction temperatures on the conversion rate of catechins are shown in Table 3. It can be seen from Table 3 that when the reaction temperature is 60°C, the conversion rate of catechin is higher.

[0035] Table 3 Effects of different reaction temperatures on the conversion rate of catechins

[0036]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com