Preparation method of mildewproof waterborne coating

A water-based coating and anti-mildew technology, which is applied in the direction of anti-fouling/underwater coatings, coatings, fibrous fillers, etc., can solve the problem of poor persistence of inorganic anti-fungal agents, aging and decomposition of organic anti-fungal agents, and affecting coating film formation Solve problems such as resistance, achieve excellent application value, fast curing, and strengthen the effect of film formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

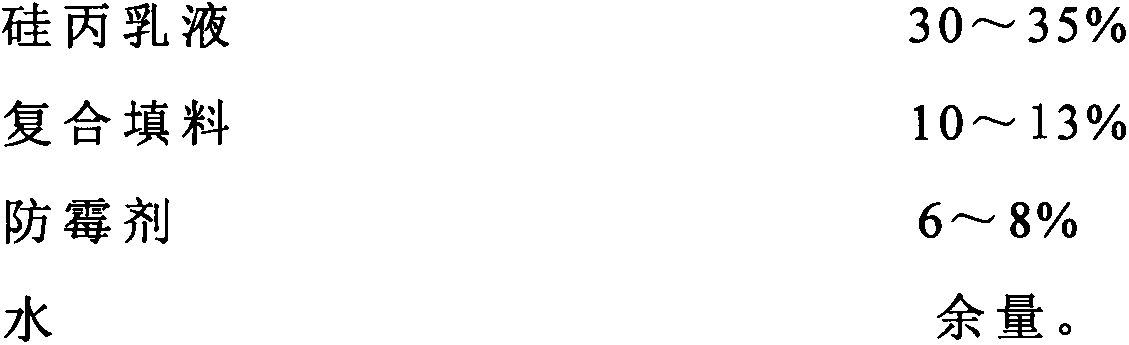

Examples

Synthetic example 1

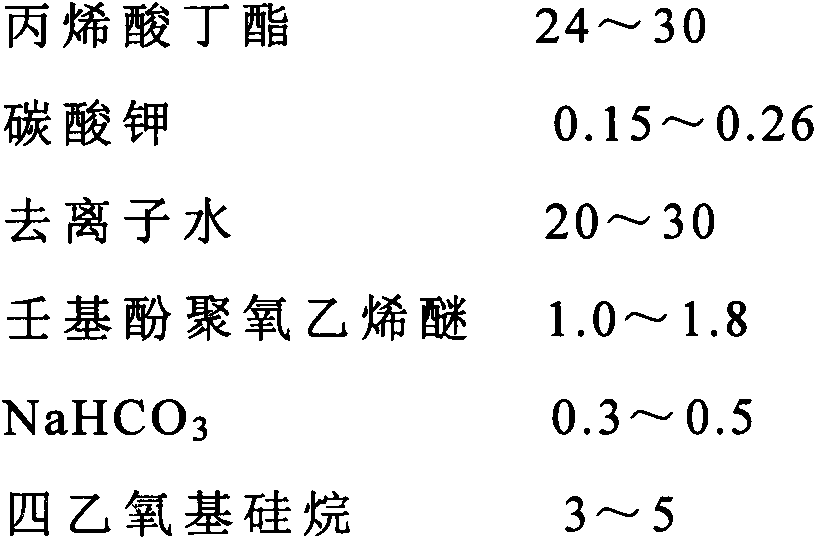

[0027] Synthesis Example 1 Synthesis of hydroxyl-terminated polysiloxane

[0028] Under the protection of nitrogen, add 20g of 3-glycidyl etheroxypropyl trimethoxysilane and 2g of tetramethyltetravinyl cyclotetrasiloxane into 40g of distilled water, mix well, then add 0.001g of tetramethyl sodium hydroxide , heat up to 60°C, stir and react for 30 minutes, then add 6g of hydroxy silicone oil, heat to 80°C, react for 20 minutes, cool down naturally, let stand to separate layers, take the lower layer solution, wash with water, and dry to obtain hydroxyl-terminated polysiloxane. Molecular weight 900~1500.

Synthetic example 2

[0029] Synthetic Example 2 Synthesis of bromine-containing compounds

[0030] Add 80g of potassium bromide and 0.4g of sodium silanolate to 100g of diethylene glycol, stir and react in an ice-water bath for 3 hours, raise the temperature to room temperature, and stir for 2 hours to react; wash the reaction product twice with water, separate the organic layer, anhydrous magnesium sulfate Drying, filtering, and distilling out the product under reduced pressure are bromine-containing compounds; the reaction formula is as follows:

[0031]

Synthetic example 3

[0032] Preparation of Synthetic Example 3 Composite Filler

[0033] Mix 500g of raw shell powder and 100g of aluminum phosphate evenly and sinter at 600°C for 25min, then crush the sintered body and select powder with a particle size of 0.8-1.2μm; then carry out surface treatment on the powder, specifically put 200g of powder into Add 2000g of ethanol and 2.2g of hydroxyl-terminated polysiloxane powder into the container, stir for 45min, and finally dry to obtain the composite filler.

[0034] Preparation of synthetic example 4 antifungal agent

[0035] The main reactions are as follows:

[0036]

[0037] Add 100 g of bromine-containing compound, 40 g of methyl p-hydroxybenzoate, and 12 g of potassium carbonate to 80 g of butanone, reflux for 2 hours, cool to room temperature, filter with suction, and dry the filter residue at 80° C. for 1 hour to obtain a solid powder; Solid powder, lanthanum trifluoromethanesulfonate (La(OTf) 3 ) 1g and imidazole 260g are mixed uniform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com