Trace nitroaromatic explosive visual inspection quantum dot test paper and preparation method thereof

A technology of nitroaromatic explosives and quantum dots, which is applied in chemical instruments and methods, fluorescence/phosphorescence, luminescent materials, etc., can solve the problems of complicated design and preparation steps of fluorescence ratio probes, and achieves improved visualization selectivity and improved vision. poor effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

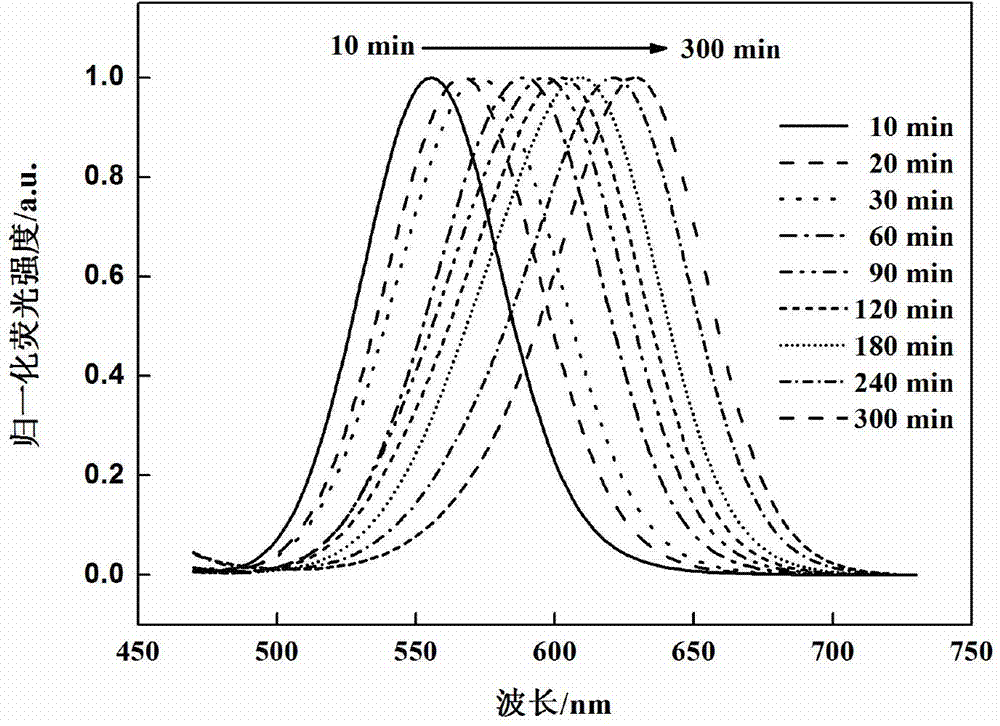

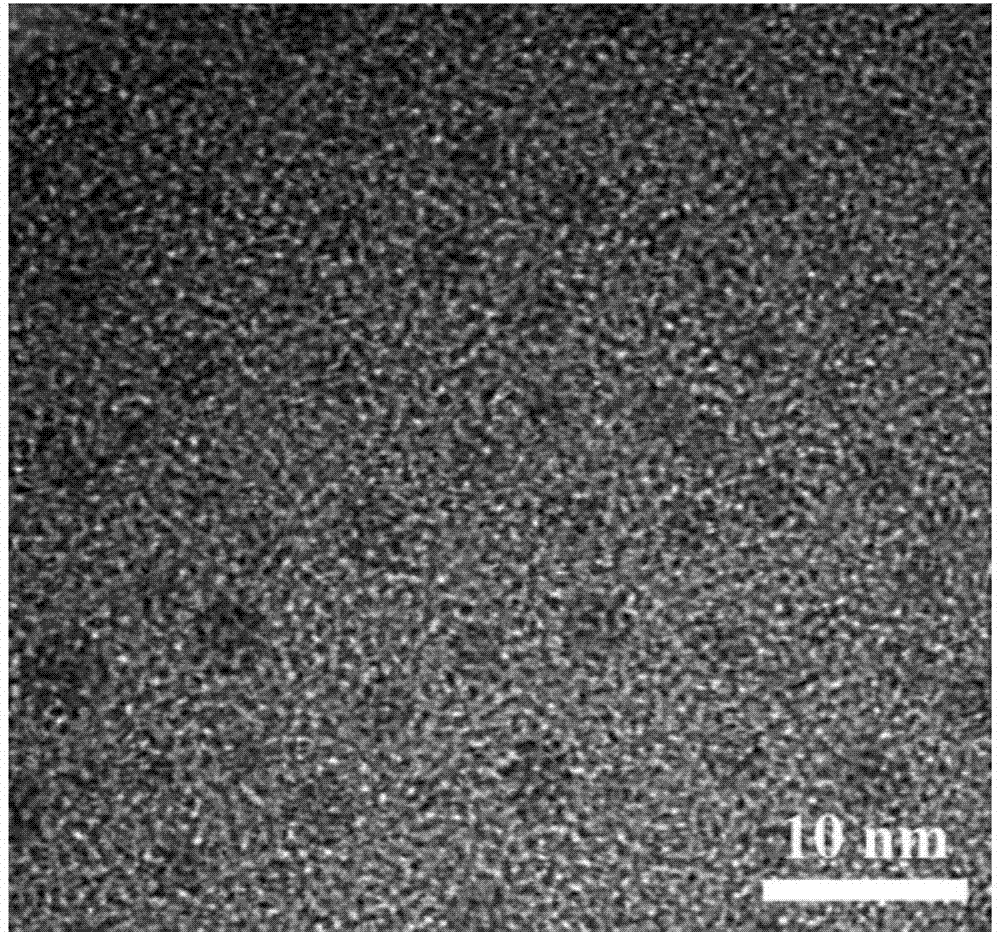

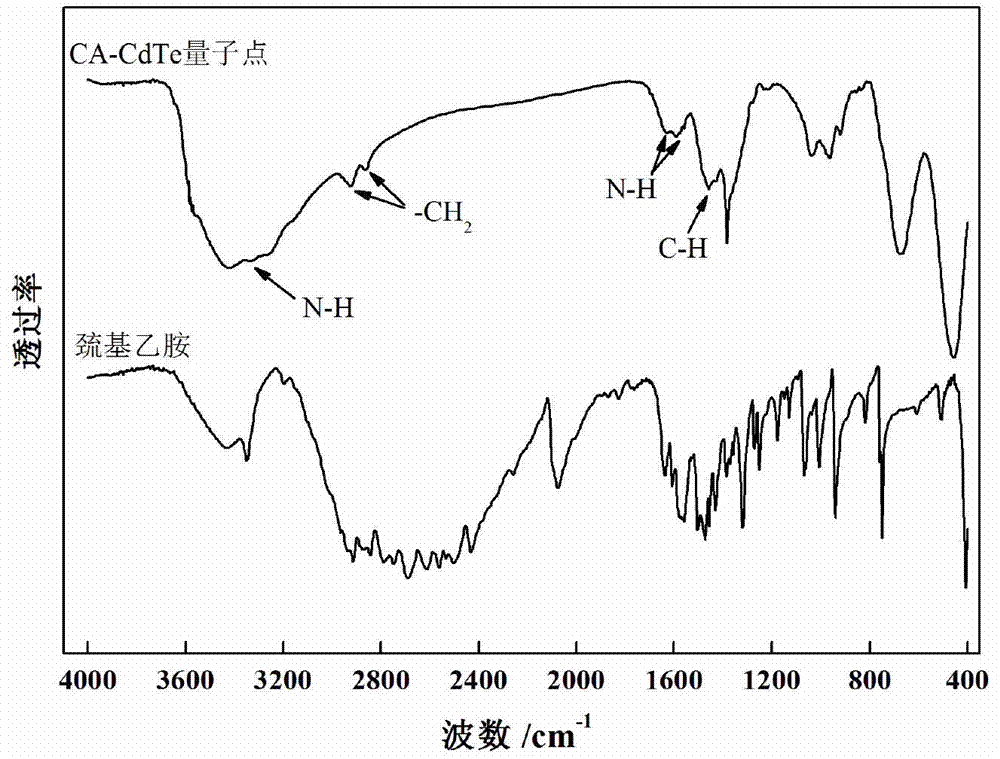

[0038] The preparation method of CdTe quantum dots with different emission wavelengths comprises the following steps:

[0039] Step 1: Prepare different emission wavelengths of mercaptoethylamine-modified CdTe quantum dot fluorescent probe CA-CdTe: 0.3856g Cd(NO 3 ) 2 4H 2 O was added to 250mL of deoxygenated ultrapure water, followed by 0.1205g of mercaptoethylamine, and then 1M (M in this application is the abbreviation of mol / L) NaOH solution to adjust its pH value to 10.0 to form mercapto-containing compounds and cadmium ions mixed solution. 0.0555g Na 2 TeO 3 Added to the mixed solution, dissolved by ultrasonic vibration, added freshly prepared NaBH 4 The solution, after stirring for 20 minutes, was heated to reflux. By controlling the reflux time from 10 to 300 minutes, an aqueous solution of cadmium telluride quantum dots with green to red luminescent bands aminated on the surface can be obtained. The prepared quantum dot stock solution was irradiated under a 15W...

Embodiment 2

[0043] The preparation method of the quantum dot test paper for the visual detection of trace nitroaromatic explosives comprises the following steps:

[0044] Step 1: Prepare mercaptoethylamine-modified CdTe quantum dot fluorescent probe CA-CdTe: 0.3856gCd(NO 3 ) 2 4H 2 O was added to 250 mL of deoxygenated ultrapure water, followed by 0.1205 g of mercaptoethylamine, and the pH was adjusted to 10.0 with 1M NaOH solution to form a mixed solution containing mercapto compounds and cadmium ions. 0.0555g Na 2 TeO 3 Added to the mixed solution, dissolved by ultrasonic vibration, added freshly prepared NaBH 4 The solution, after stirring for 20 minutes, was heated to reflux. By controlling the reflux time to 300 minutes, an aqueous solution of cadmium telluride quantum dots with surface amination and emitting red fluorescence can be obtained. The prepared quantum dot stock solution was irradiated under a 15W ultraviolet lamp to increase the fluorescence quantum yield, and it wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com