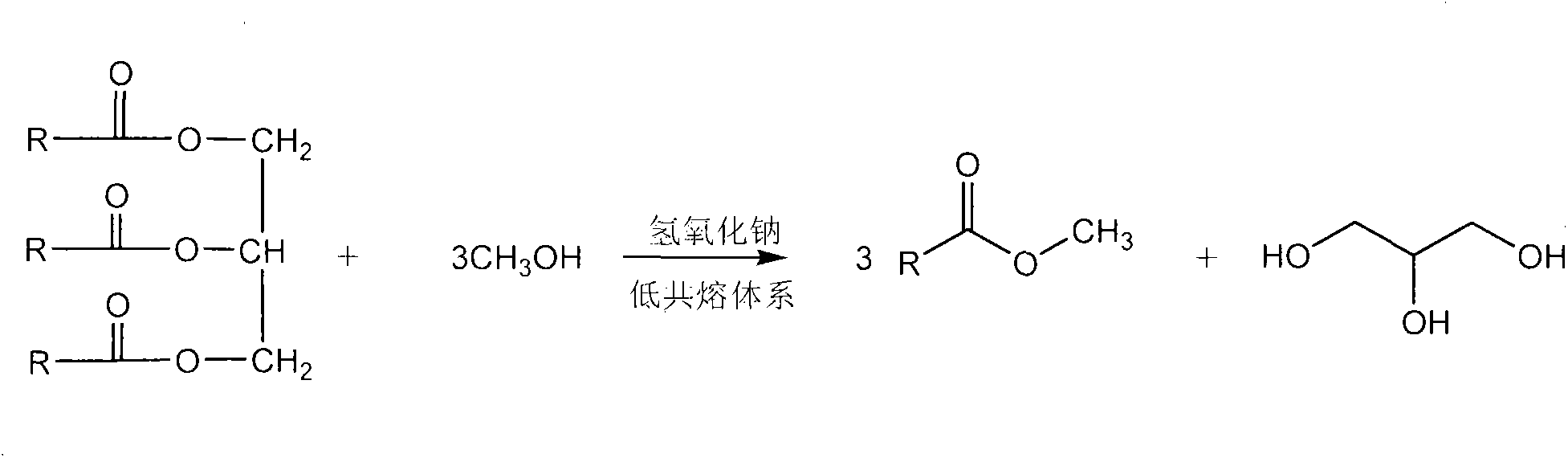

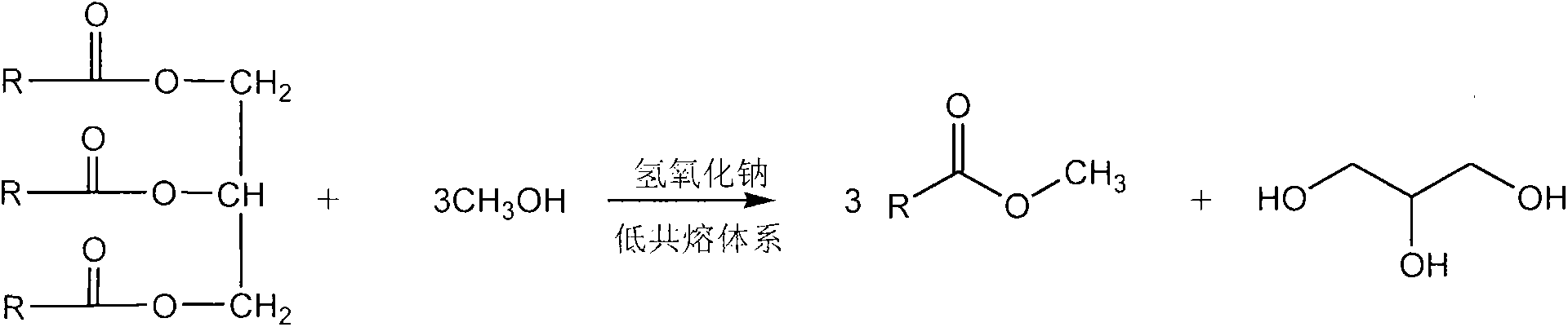

Method for preparing biodiesel in eutectic system

A biodiesel, eutectic technology, applied in biofuels, petroleum industry, liquid carbon-containing fuels, etc., can solve the problems of strong catalyst corrosion, easy saponification of products, secondary pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] In a 100mL three-neck round bottom flask, add 30g (0.034mol) soybean oil (average molecular weight 878.25) and preheat it in a water bath at 65°C, then add 0.3g (0.0075mol) NaOH, 6g methanol (0.1875mol), 3g ethanol Melt solvent (choline chloride / glycerol molar ratio is 1:1), stirred and refluxed under normal pressure, 65°C water bath for 4.0 hours, cooled to room temperature, transferred to a separatory funnel for layering (rapid layering), The lower layer is a mixture of excess methanol, glycerin, ionic liquid, and NaOH; the upper layer is the product. After washing with hot water for 3 to 5 times, vacuum drying at 400 Pa and 80° C. gives 25.7 g of pure product with a yield of about 85%.

Embodiment 2

[0023] In a 100mL three-neck round bottom flask, add 30g (0.034mol) soybean oil (average molecular weight 878.25) and preheat it in a water bath at 65°C, then add 0.15g of NaOH, 10.9g of methanol (0.34mol), 4.5g of eutectic Solvent (choline chloride / glycerol molar ratio is 1:1), stirred and refluxed under normal pressure, 65°C water bath for 2.0 hours, cooled to room temperature, transferred to a separating funnel for layering (rapid layering), the lower layer It is a mixture of excess methanol, glycerin, ionic liquid, and NaOH; the upper layer is the product, after washing with hot water for 3 to 5 times, vacuum drying at 400 Pa and 80°C to obtain 26.0 g of pure product, with a yield of about 86%.

Embodiment 3

[0025] In a 100mL three-neck round bottom flask, add 30g soybean oil (average molecular weight 878.25) and preheat it in a water bath at 65°C, then add 1.5g of NaOH, 8g of methanol, 4g of deep eutectic solvent (choline chloride / glycerol The molar ratio is 1:1.19), stirred and refluxed for 3.0 hours under normal pressure, 65 °C water bath, cooled to room temperature, transferred to a separatory funnel for layering (rapid layering), the lower layer is excess methanol, glycerol, ionic liquid, NaOH The upper layer is the product, after washing with hot water for 3 to 5 times, vacuum drying at 400 Pa and 80° C. to obtain 26.6 g of the pure product, with a yield of about 88%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com