Preparation methods of high-water-stability conductive poly(3,4-ethylenedioxythiophene):poly(styrenesulfonate) composite electrode

A technology of ethylenedioxythiophene and polystyrene sulfonic acid, which is applied in the direction of electrochemical variables of materials, can solve the problems such as the decrease of conductivity of PEDOT:PSS film, and achieves low preparation cost, good water stability and excellent stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Preparation method of highly water-stable conductive poly(3,4-ethylenedioxythiophene):polystyrenesulfonic acid (PEDOT:PSS) composite electrode:

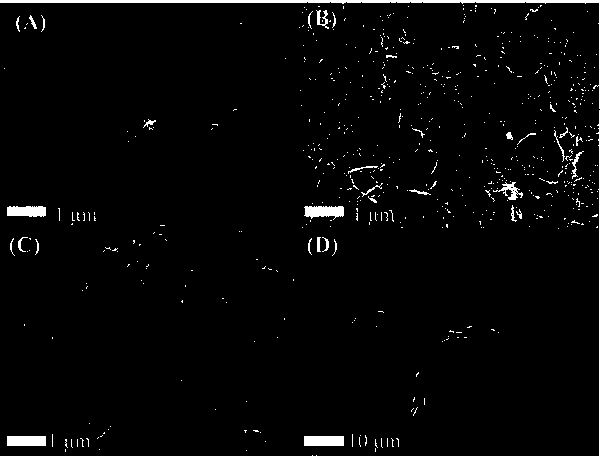

[0016] 1. Preparation of PEDOT:PSS-PVA composite electrode: Mix and stir 1.3% PEDOT:PSS aqueous dispersion and 2% PVA solution at a volume ratio of 9:1 for 24 hours to obtain PEDOT:PSS-PVA Mixed solution; the obtained PEDOT:PSS-PVA mixed solution is drop-coated on the surface of the polished glassy carbon electrode, and dried at a constant temperature of 50° C. to obtain a PEDOT:PSS-PVA composite electrode.

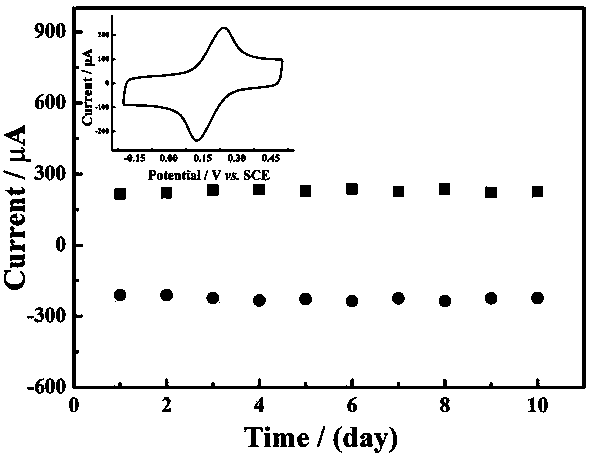

[0017] 2. Preparation and application of PEDOT:PSS-PVA-MWCNTs composite electrode: According to the ratio of PEDOT:PSS to MWCNTs volume ratio of 1:2, add 4.0% mass fraction of MWCNTs dispersion to the PEDOT:PSS-PVA mixture , and stirred for 24 hours, 5 μL of the obtained mixture was drop-coated on the surface of the pretreated glassy carbon electrode, and dried at a constant temperature of 50 ° C to obtain a PEDOT:PSS-PVA...

Embodiment 2

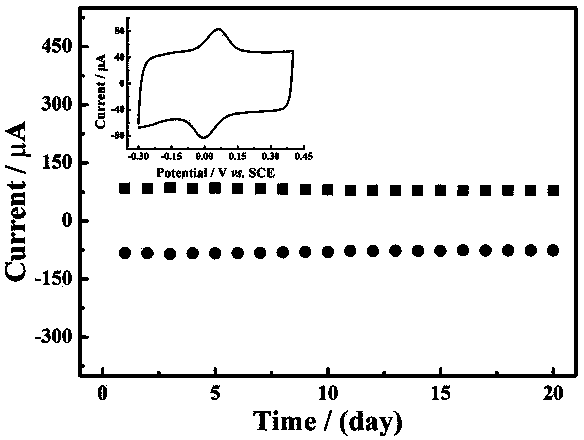

[0021]A method for preparing a highly water-stable conductive PEDOT:PSS composite electrode, first preparing P(EDOT:EDOT-AA):PSS dispersion, by grafting hydrophobic functional groups AA on EDOT, EDOT and EDOT- AA copolymerization, the mass ratio of the two is 5:1, the obtained copolymer is dispersed in the PSSNa solution to obtain the P(EDOT:EDOT-AA):PSS dispersion liquid, and the obtained mixed solution is taken 5 μL and drip-coated on the The surface of the pretreated glassy carbon electrode was dried at a constant temperature of 50°C to obtain a P(EDOT:EDOT-AA):PSS composite electrode. Use this electrode for the detection of biomolecules and contaminants. P(EDOT:EDOT-AA):PSS composite electrode is used for the detection of biomolecules: ①Place the P(EDOT:EDOT-AA):PSS modified electrode in PBS solution containing a certain concentration of epinephrine, and use linear scanning Voltammetric (LSV) detection of epinephrine. Linear range of epinephrine: 0.2-15 μM and 20-100 μM ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com