Method for preparing mesoporous material from hydroxyapatite

A technology of hydroxyapatite and mesoporous materials, applied in chemical instruments and methods, adsorption water/sewage treatment, other chemical processes, etc., can solve the problem that high specific surface area, iron-modified apatite mesoporous materials cannot be prepared and other problems, to achieve the effect of simple preparation process, low economic cost of raw materials, and good dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0017] Specific embodiment one: In this embodiment, a method for preparing mesoporous materials with hydroxyapatite is carried out according to the following steps:

[0018] 1. Mix hydroxyapatite and iron salt solution with a concentration of 0.01-0.05mol / L in a ratio of 8-10g:1L by mass to volume, and then stir the mixture at a speed of 180-300r / min for 10- 20min to obtain iron-modified hydroxyapatite, wherein the temperature of the iron salt aqueous solution is 25°C to 30°C;

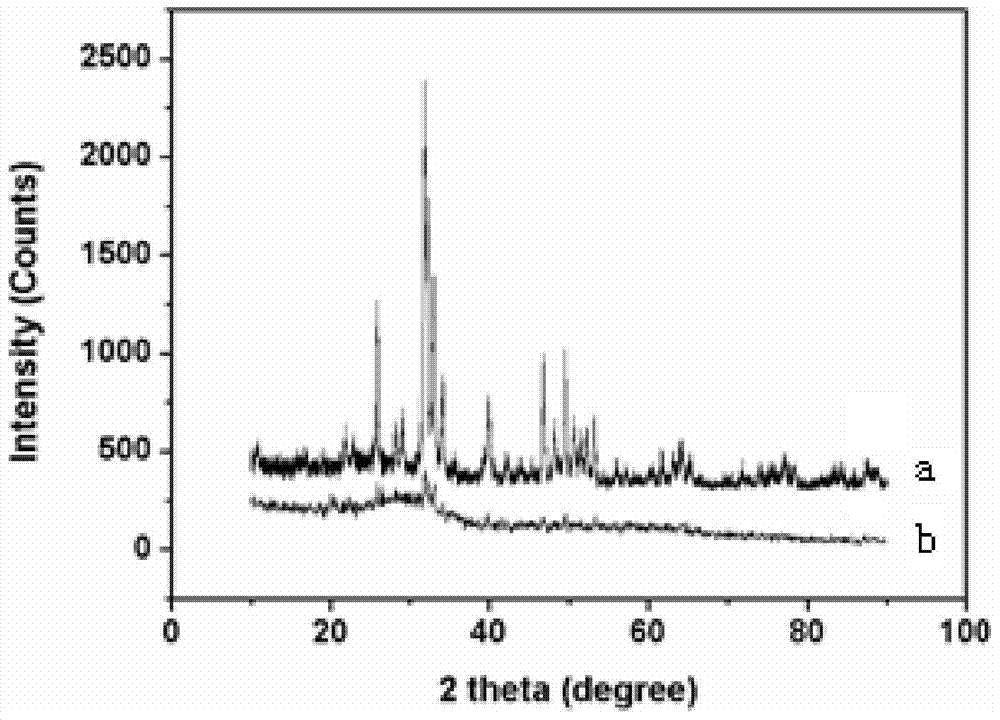

[0019] 2. Wash the iron-modified hydroxyapatite obtained in step 1 with deionized water until the pH value is 5 to 7, and dry the washed iron-modified hydroxyapatite at 105°C to 110°C for 22-22°C. After 26 hours, the iron-modified hydroxyapatite mesoporous material was obtained.

[0020] The beneficial effect of this implementation mode:

[0021] 1. This embodiment uses hydroxyapatite synthesized directly from natural shell powder at medium and low temperature as the raw material, which has the chara...

specific Embodiment approach 2

[0024] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the iron salt described in step one is ferric nitrate, ferric sulfate, FeNH 4 (SO 4 ) 2 or ferric chloride. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0025] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that in Step 1, the hydroxyapatite and the iron salt solution with a concentration of 0.035 mol / L are 8 to 10 g in mass to volume ratio. : Mix in 1L proportion. Others are the same as in the first or second embodiment.

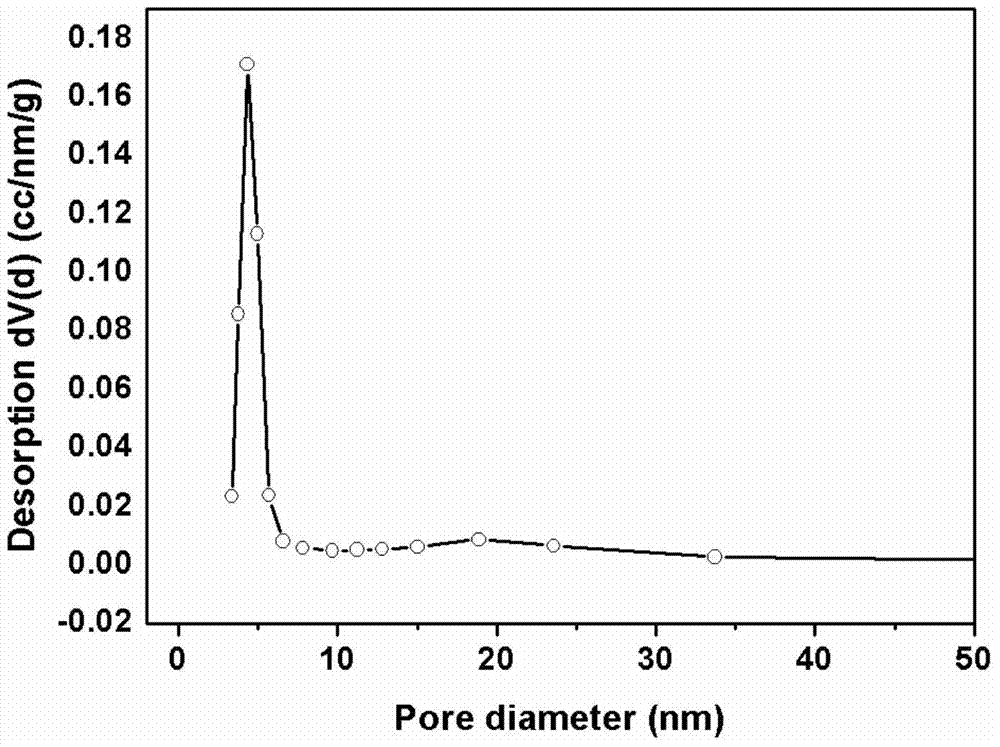

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com