Single-step hydrothermal micro-emulsion method for preparing iron-doped nano titanium dioxide powder

A nano-titanium dioxide and microemulsion method is applied in the preparation of iron-doped nano-titanium dioxide powder, and in the field of preparation of nano-titanium dioxide powder, and achieves the effects of simple equipment, controllable size, and avoiding the influence of morphology and stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

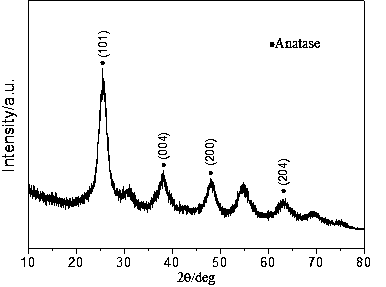

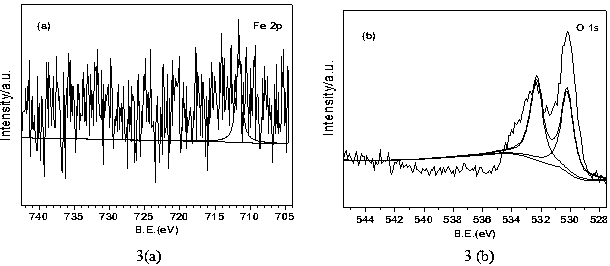

[0035] Add 8 ml alkylphenol polyoxyethylene ether (OP-10), 12 ml n-butanol (C 4 h 9 OH), 40 ml cyclohexane (C 6 h 12 ), 4 ml butyl titanate (Ti(OC 4 h 9 ) 4 and 4 ml of ferric chloride (1 M) in hydrochloric acid (0.1 M), that is, the volume ratio of butyl titanate: alkylphenol ethoxylate: n-butanol: cyclohexane is 1:2:3:10 , stirred evenly for 15 min, the ratio of oil to water in the above water-in-oil W / O microemulsion was 10:1, and then transferred to a 100 ml polytetrafluoroethylene-lined hydrothermal reaction kettle, and put it into a 120 ℃ constant temperature drying oven. Under solvothermal conditions, the reaction was kept for 1 h. After the reaction, it was naturally cooled to room temperature, ultrasonically cleaned three times with distilled water and absolute ethanol, each time for 50 min, and the product was vacuum-dried in a drying oven at 60 °C for 24 h. The titanium dioxide powder prepared by this step has a diameter of about 10-25 nm.

Embodiment 2

[0037] Add 8 ml alkylphenol polyoxyethylene ether (OP-10), 12 ml n-butanol (C 4 h 9 OH), 40 ml cyclohexane (C 6 h 12 ), 4 ml butyl titanate (Ti(OC 4 h 9 ) 4 and 4 ml of ferric chloride (1 M) in hydrochloric acid (0.1 M), that is, the volume ratio of butyl titanate: alkylphenol ethoxylate: n-butanol: cyclohexane is 1:2:3:10 , stirred evenly for 15 min, the ratio of oil to water in the above water-in-oil W / O microemulsion was 10:1, and then transferred to a 100 ml polytetrafluoroethylene-lined hydrothermal reaction kettle, and put it into a 140 ℃ constant temperature drying oven. Under solvothermal conditions, the reaction was kept for 1 h. After the reaction, it was naturally cooled to room temperature, ultrasonically cleaned three times with distilled water and absolute ethanol, each time for 40 min, and the product was vacuum-dried in a drying oven at 60 °C for 24 h. The titanium dioxide powder prepared by this step has a diameter of about 10-25 nm.

Embodiment 3

[0039] Add 8 ml alkylphenol polyoxyethylene ether (OP-10), 12 ml n-butanol (C 4 h 9 OH), 40 ml cyclohexane (C 6 h 12 ), 4 ml butyl titanate (Ti(OC 4 h 9 ) 4 and 4 ml of ferric chloride (1 M) in hydrochloric acid (0.1 M), that is, the volume ratio of butyl titanate: alkylphenol ethoxylate: n-butanol: cyclohexane is 1:2:3:10 , stirred evenly for 15 min, the ratio of oil to water in the above water-in-oil W / O microemulsion was 10:1, and then transferred to a 100 ml polytetrafluoroethylene-lined hydrothermal reaction kettle, and put it into a constant temperature drying oven at 160 °C. Under solvothermal conditions, the reaction was kept for 1 h. After the reaction, it was naturally cooled to room temperature, ultrasonically cleaned three times with distilled water and absolute ethanol, each time for 30 min, and the product was vacuum-dried in a drying oven at 60 °C for 24 h. The titanium dioxide powder prepared by this step has a diameter of about 10-25 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com