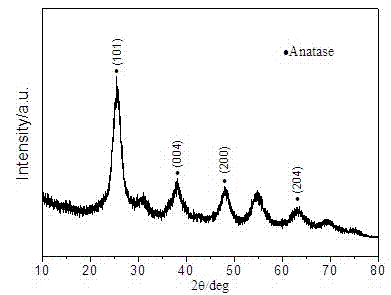

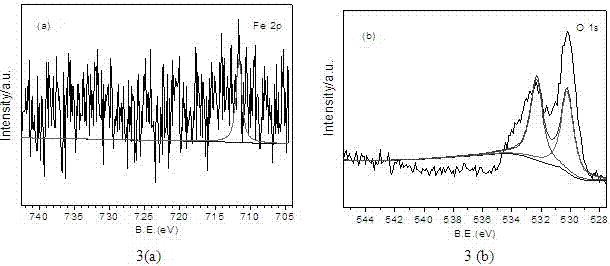

Single-step hydrothermal micro-emulsion method for preparing iron-doped nano titanium dioxide powder

A technology of nano-titanium dioxide and microemulsion method, which is applied in the preparation of iron-doped nano-titanium dioxide powder and the field of nano-titanium dioxide powder preparation, to achieve the effect of simple equipment, controllable size and high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

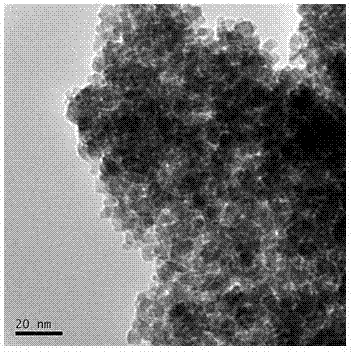

Embodiment 1

[0034] Add 8 ml of alkylphenol polyoxyethylene ether (OP-10), 12 ml of n-butanol (C 4 H 9 OH), 40 ml cyclohexane (C 6 H 12 ), 4 ml butyl titanate (Ti(OC) 4 H 9 ) 4 and 4 ml of ferric chloride (1 M) in hydrochloric acid (0.1 M) in a volume ratio of butyl titanate: alkylphenol ethoxylate: n-butanol: cyclohexane 1:2:3:10 , stir evenly for 15 min, the ratio of oil to water in the above-mentioned water-in-oil W / O microemulsion is 10:1, then transferred to a 100 ml lined polytetrafluoroethylene hydrothermal reaction kettle, put into a constant temperature drying oven at 120 °C, The reaction was kept for 1 h under solvothermal conditions. After the reaction, it was naturally cooled to room temperature, and ultrasonically washed three times with distilled water and absolute ethanol for 50 min each time. The diameter of titanium dioxide powder prepared by this step is about 10-25 nm.

Embodiment 2

[0036] Add 8 ml of alkylphenol polyoxyethylene ether (OP-10), 12 ml of n-butanol (C 4 H 9 OH), 40 ml cyclohexane (C 6 H 12 ), 4 ml butyl titanate (Ti(OC) 4 H 9 ) 4 and 4 ml of ferric chloride (1 M) in hydrochloric acid (0.1 M) in a volume ratio of butyl titanate: alkylphenol ethoxylate: n-butanol: cyclohexane 1:2:3:10 , stir evenly for 15 min, the ratio of oil to water in the above-mentioned water-in-oil W / O microemulsion is 10:1, then transferred to a 100 ml lined polytetrafluoroethylene hydrothermal reaction kettle, put into a constant temperature drying oven at 140 °C, The reaction was kept for 1 h under solvothermal conditions. After the reaction, it was naturally cooled to room temperature, and ultrasonically cleaned with distilled water and absolute ethanol for three times each for 40 min. The product was dried in a drying oven at 60 °C for 24 h under vacuum. The diameter of titanium dioxide powder prepared by this step is about 10-25 nm.

Embodiment 3

[0038] Add 8 ml of alkylphenol polyoxyethylene ether (OP-10), 12 ml of n-butanol (C 4 H 9 OH), 40 ml cyclohexane (C 6 H 12 ), 4 ml butyl titanate (Ti(OC) 4 H 9 ) 4 and 4 ml of ferric chloride (1 M) in hydrochloric acid (0.1 M) in a volume ratio of butyl titanate: alkylphenol ethoxylate: n-butanol: cyclohexane 1:2:3:10 , stir evenly for 15 min, the ratio of oil to water in the above-mentioned water-in-oil W / O microemulsion is 10:1, then transferred to a 100 ml lined polytetrafluoroethylene hydrothermal reaction kettle, and put into a constant temperature drying oven at 160 °C, The reaction was kept for 1 h under solvothermal conditions. After the reaction, it was naturally cooled to room temperature, and ultrasonically cleaned with distilled water and absolute ethanol for three times each for 30 min. The product was dried in a drying oven at 60 °C for 24 h under vacuum. The diameter of titanium dioxide powder prepared by this step is about 10-25 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com