Bin type sludge aerobic composting method

A kind of aerobic composting and sludge technology, applied in the direction of organic fertilizer, fertilization device, organic fertilizer preparation, etc., can solve the problems of uneven material mixing, large processing capacity, anaerobic, etc., and achieve the effect of sufficient and uniform air distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

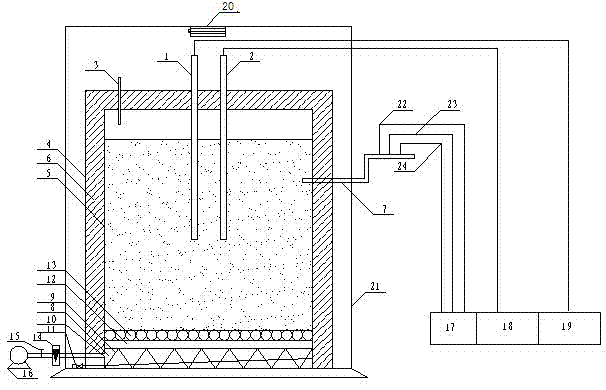

[0023] (1) Bin-type sludge aerobic composting device such as figure 1 , including fermentation bins, ventilation devices and real-time online monitoring equipment; the outer dimensions of the fermentation bins are?×H=800mm×1300mm, and the effective volume is?×H=600mm×1100mm. The fermentation bins are installed on stainless steel brackets 21 and stainless steel brackets 21 0.5t-1.0t electric hoist 20 is set; the temperature probe 1, the oxygen probe 2 and the exhaust pipe 3 are installed on the top of the fermentation chamber. Form the thermal air insulation layer 6; the side wall of the fermentation bin is provided with an exhaust pipe 7; the bottom of the fermentation bin is provided with a buffer layer 8, a guide flap 9, an air inlet 10 and a drain pipe 11; the thickness of the buffer layer 8 is 25cm, and the guide Folded plate 9 is zigzag, and inclination angle is 90 degrees; The deflector flap 9 is provided with hole cover plate 12; Where the air duct is close to the air ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com