Novel irradiation indication film and preparation method thereof

An irradiation and film technology, applied in the field of irradiation indicator cards, can solve problems such as the inability to quantitatively mark the radiation dose, the response sensitivity needs to be improved, and the production cost is restricted, so as to increase output and productivity, improve product quality, and accelerate dissolution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

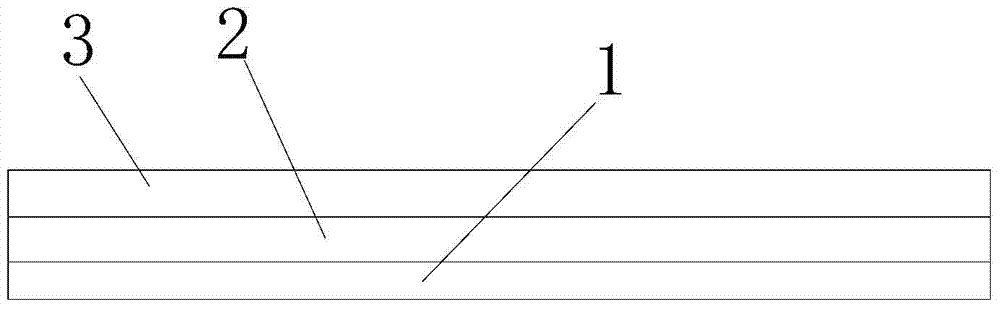

[0036] A novel radiation indicating film, comprising the following steps:

[0037] 1) Prepare the color-changing coating solution:

[0038] Weigh 0.6g of PVB (polyvinyl alcohol carboxybutyraldehyde), 0.4g of 10,12-tracosadiynoic acid and 1.2 of 1-hydroxycyclohexyl phenyl ketone (184) with an electronic balance; Measure 10ml of absolute ethanol; pour the above-mentioned raw materials into a beaker, stir with a magnetic stirrer, and after stirring evenly, obtain a color-changing coating solution;

[0039] 2) Make radiation indicating film:

[0040] Wash the polyester substrate with absolute ethanol and dry it; use an automatic dispensing robot to spot the color-changing coating solution in step 1) on the polyester substrate to form a color-changing coating; the color-changing coating after drying The coating thickness is 150 μm. After drying, a protective film is placed on top of the color-changing coating; the end result is the new radiation indicating film.

[0041] In pra...

specific Embodiment 2

[0043] A novel radiation indicating film, comprising the following steps:

[0044] 1) Prepare the color-changing coating solution:

[0045] Weigh 0.7g of PVB (polyvinyl alcohol carboxybutyraldehyde), 0.5g of 10,12-tracosadiynoic acid and 1.3g of 1-hydroxycyclohexyl phenyl ketone (184) with an electronic balance; Measure 10ml of absolute ethanol in a graduated cylinder; pour the above-mentioned raw materials into a beaker, stir with a magnetic stirrer, and after stirring evenly, obtain a color-changing coating solution;

[0046]2) Make radiation indicating film:

[0047] Wash the polyester substrate with absolute ethanol and dry it; use an automatic dispensing robot to spot the color-changing coating solution in step 1) on the polyester substrate to form a color-changing coating; the color-changing coating after drying The coating thickness was 170 μm. After drying, a protective film is placed on top of the color-changing coating; the end result is the new radiation indicati...

specific Embodiment 3

[0049] A novel radiation indicating film, comprising the following steps:

[0050] 1) Prepare the color-changing coating solution:

[0051] Weigh 0.5g of PVB (polyvinyl alcohol carboxybutyraldehyde), 0.4g of 10,12-tracosadiynoic acid and 1.3g of 1-hydroxycyclohexyl phenyl ketone (184) with an electronic balance; Measure 10ml of absolute ethanol in a graduated cylinder; pour the above-mentioned raw materials into a beaker, stir with a magnetic stirrer, and after stirring evenly, obtain a color-changing coating solution;

[0052] 2) Make radiation indicating film:

[0053] Wash the polyester substrate with absolute ethanol and dry it; use an automatic dispensing robot to spot the color-changing coating solution in step 1) on the polyester substrate to form a color-changing coating; the color-changing coating after drying The coating thickness was 130 μm. After drying, a protective film is applied on top of the color-changing coating; the result is a novel radiation indicating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com