Granules and method for producing same, production method for molten glass, and production method for glass article

A manufacturing method and technology for melting glass, which are applied in glass forming, manufacturing tools, feeding of melting furnaces, etc., can solve the problems of unstable glass composition, scattering of raw material powder, waste of raw materials, etc., and achieve good composition uniformity and strength. Good results with excellent strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example 1~14

[0221]

[0222] [Glass composition]

[0223] As for the glass composition, 11 types of G1 to G11 shown in Table 1 were used. The unit is mol%.

[0224] [Table 1]

[0225] glass composition

G1

G2

G3

G4

G5

G6

G7

G8

G9

G10

G11

SiO 2

64.6

65.2

65.5

65.7

65.7

65.8

62.1

61.0

60.2

66.8

68.7

al 2 o 3

11.0

11.1

11.2

11.2

11.2

11.2

10.6

10.4

10.3

7.9

8.1

B 2 o 3

7.7

3.9

2.0

1.0

0.5

0.0

7.4

3.7

0.9

5.2

0.0

MgO

5.2

4.9

4.7

4.6

4.6

4.5

5.0

4.5

4.2

0.0

0.0

CaO

4.6

4.7

4.7

4.7

4.7

4.7

12.8

18.4

22.4

0.0

0.0

SrO

4.7

8.1

9.8

10.7

11.2

11.6

0.0

0.0

0.0

0.0

0.0

BaO

0.0

0.0

0.0

0.0

0.0

0.0

0.0

...

manufacture example 6

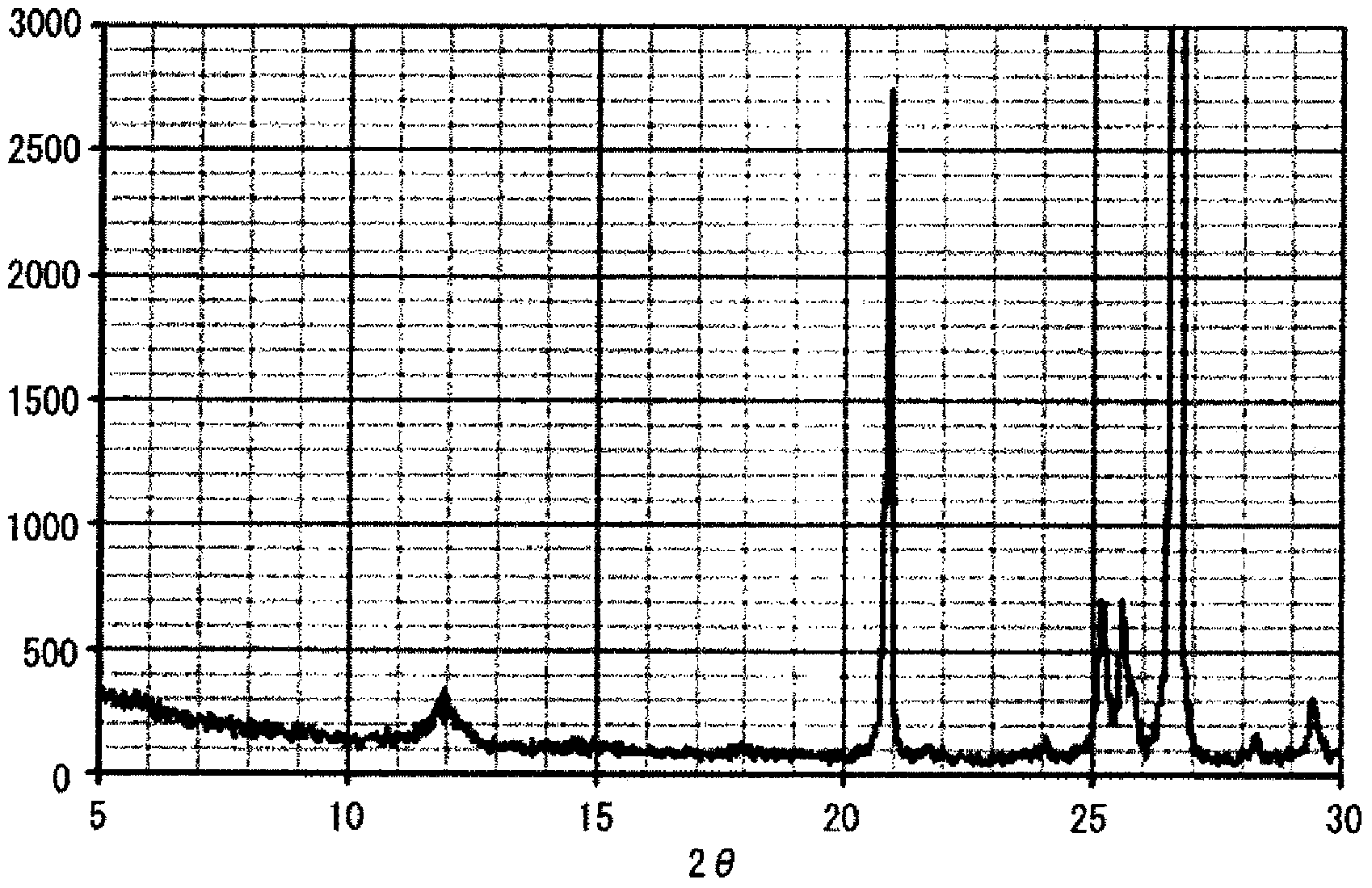

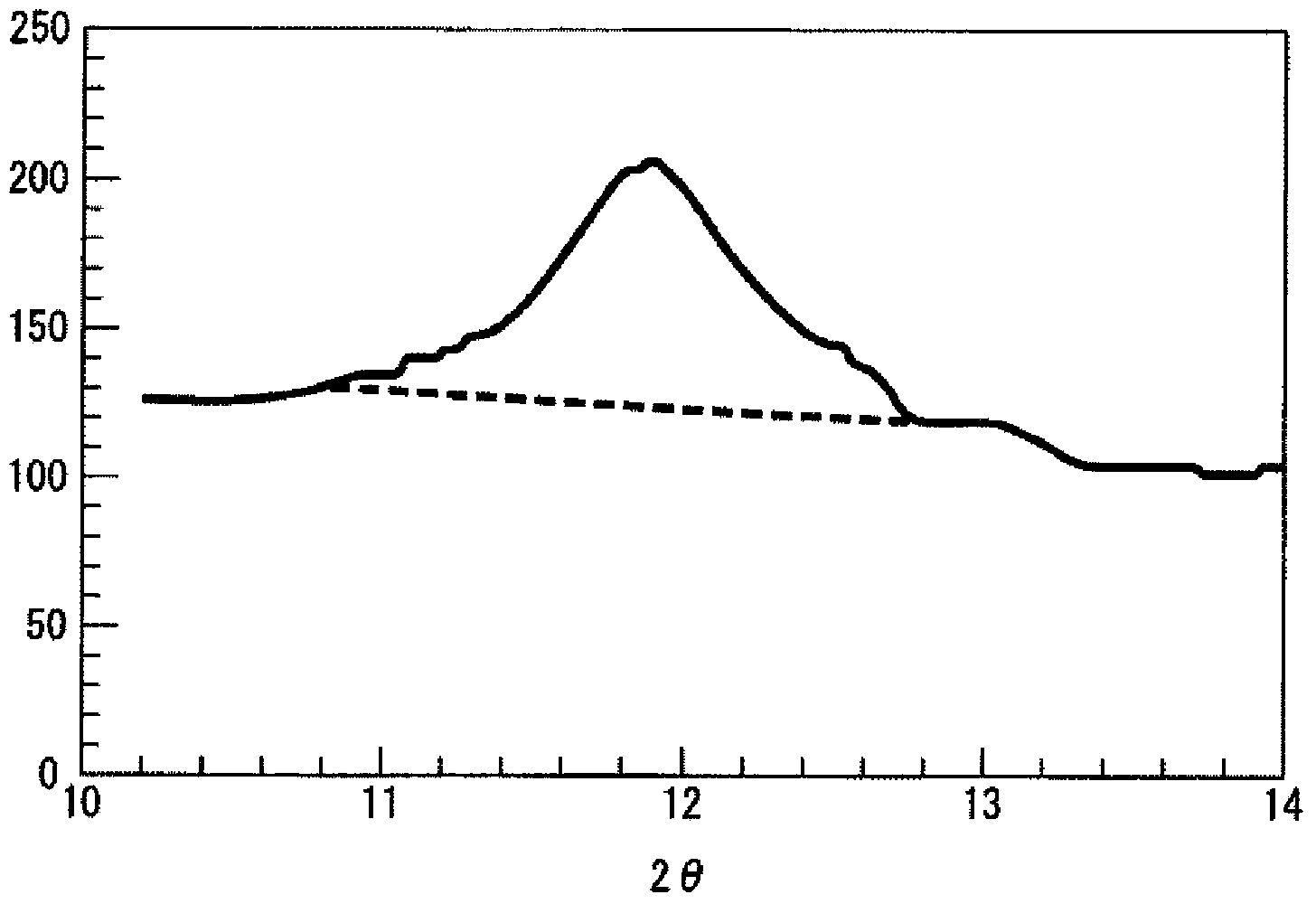

[0274] B in the glass composition (G5) of Production Example 6 2 o 3 The glass composition (G6) of Production Example 7 and the glass composition (G11) of Production Example 16 do not contain boric acid. Therefore, the hydrate (x 2 The value of the relative diffraction peak area of )[boric acid Sr hydrate] was zero, and good strength of the granules could not be obtained. In addition, the hydrate (x 1 ) [boric acid Ca hydrate] relative diffraction peak area is also zero, the hydrate (x 3 ) [Ba hydrate of boric acid] has a relative diffraction peak area of zero.

[0275] Production Examples 8 to 10 are examples in which neither SrO nor BaO is contained in the glass composition. The content of calcium carbonate in the glass composition (G9) of Production Example 10 was large, and B 2 o 3 The content is less. Therefore, the hydrate (x 1 ) [boric acid Ca hydrate] had a relative diffraction peak area value of zero, and good strength of the granules could not be obtaine...

manufacture example 12

[0276] The glass compositions (G1) of Production Examples 12 and 13 are the same as those of Production Examples 1 and 2, but Production Example 12 is an example in which calcium carbonate and magnesium carbonate are used instead of dolomite, and Production Example 13 is an example in which dolomite is used instead of Examples of calcium hydroxide and magnesium hydroxide are used. Their hydrates (x 2 ) [boric acid Sr hydrate] has relatively low diffraction peak area values, and the intensity of granules is slightly poor. This is considered to be because the value of Z in Production Example 12 was particularly small, and the calcium source in Production Example 13 contained a particularly large amount of calcium hydroxide.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com