Lactobacillus acidophilus fermented milk and preparation method thereof

A technology of Lactobacillus acidophilus and fermented milk, which is applied in the field of Lactobacillus acidophilus fermented milk, can solve the problems of low content of Lactobacillus acidophilus, difficulty in exerting the health care and probiotic functions of Lactobacillus acidophilus, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

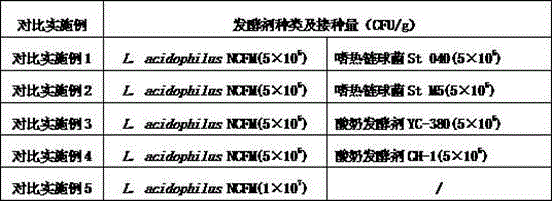

Image

Examples

Embodiment 2

[0083] ①Product ingredients: Add 30 grams of white sugar, 60 grams of fructose syrup F42, 1.5 grams of dipotassium hydrogen phosphate, 1.5 grams of potassium dihydrogen phosphate, 5 grams of trehalose and 10 grams of egg yolk peptide, after stirring evenly, add 200 grams of loquat and longan mixed fruit pulp while stirring to obtain a feed liquid;

[0084] ② Homogenization and sterilization: Preheat the prepared material liquid to heat up, after homogenizing at 60°C and 18MPa, heat and sterilize at 90°C for 10 minutes, and cool to 37°C;

[0085] ③ Product fermentation: under sterile conditions, according to the inoculum size 3 × 10 6 CFU / g was inserted into Lactobacillus acidophilus NCFM, mixed evenly, fermented at 37°C, and the fermentation was terminated when the titrated acidity of the fermentation system was measured to 85oT.

[0086] ④ Stirring and cooling: Stir and demulsify in a water bath until the fermented milk reaches 22°C to cool the fermented milk;

[0087] ⑤ Pr...

Embodiment 3

[0090] ①Product ingredients: Dragon fruit is washed, crushed, squeezed, and filtered to obtain fruit juice. Add 60 grams of white sugar, 40 grams of fructose syrup F42, 2 grams of sodium tripolyphosphate, 10 grams of trehalose, 3 grams of egg yolk peptide, and 3 grams of corn peptide were stirred evenly, and 50 grams of dragon fruit juice was added while stirring to obtain a feed liquid;

[0091] ② Homogenization and sterilization: Preheat the prepared material liquid to heat up, after homogenizing at 70°C and 22MPa, heat and sterilize at 92°C for 6 minutes, and cool to 39°C;

[0092] ③ Product fermentation: under sterile conditions, according to the inoculum size 2 × 10 6 CFU / g was inserted into Lactobacillus acidophilus NCFM, mixed evenly, fermented at 39°C, and the fermentation was terminated when the titrated acidity of the fermentation system was measured to 75oT.

[0093] ④ Stirring and cooling: stir and break the emulsion in a water bath until the fermented milk reach...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com