Preparation method of resistant starch nutritional carrier based on metal-organic framework as well as product thereof

A metal-organic framework and resistant starch technology, which is applied in the field of preparation of food-grade nutritional carriers, can solve the problems that have not yet been reported on food-grade nutritional carriers, and achieve good solution self-aggregation performance and good health effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

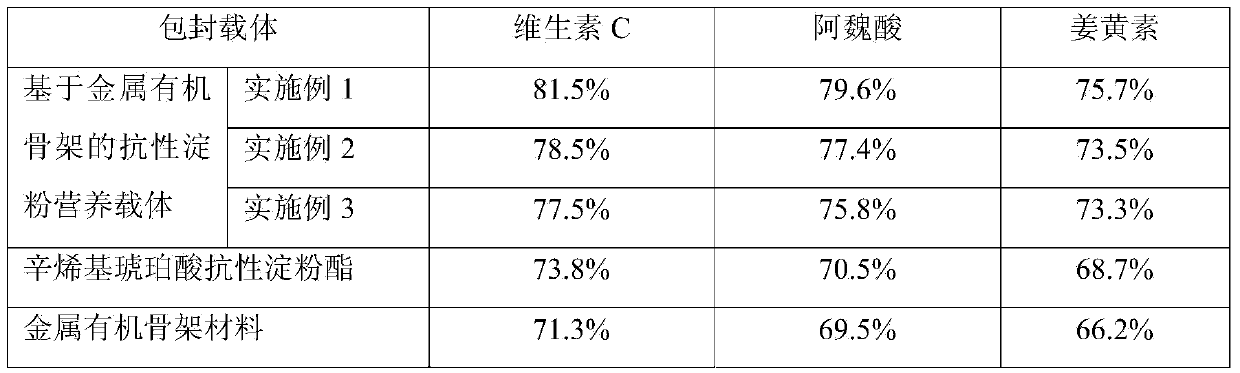

Embodiment 1

[0020] Example 1, Preparation of resistant starch nutritional carrier based on metal organic framework

[0021] The preparation method of the resistant starch nutrient carrier based on the metal organic framework comprises the following steps:

[0022] A. Preparation of octenyl succinic acid resistant starch ester: Stir 300g of resistant starch and 200mL of absolute ethanol in a high-speed mixer at 2000rpm to fully swell the resistant starch, then add 2g dropwise under stirring / mL 150mL of absolute ethanol solution of octenyl succinic anhydride, adjust the pH to 9.5 with 0.5mol / L sodium hydroxide solution, heat the reaction in a water bath at 100°C for 3h; after the reaction, adjust the pH to neutral with 0.5mol / L hydrochloric acid solution properties, filtered, the filter cake was washed with absolute ethanol, dried below 50°C, and pulverized to obtain octenyl succinic acid resistant starch ester;

[0023] B. Preparation of metal-organic framework materials: Dissolve 21.3g ...

Embodiment 2

[0026] Example 2, Preparation of resistant starch nutritional carrier based on metal organic framework

[0027] The preparation method of the resistant starch nutrient carrier based on the metal organic framework comprises the following steps:

[0028] A. Preparation of octenyl succinic acid resistant starch ester: Stir 500g of resistant starch and 300mL of absolute ethanol in a high-speed mixer at 3000rpm to fully swell the resistant starch, then add 0.96 125 mL of anhydrous ethanol solution of g / mL octenyl succinic anhydride, adjust the pH to 10.0 with 0.5 mol / L sodium hydroxide solution, and heat the reaction in a water bath at 95°C for 5 hours; after the reaction, adjust the pH to 0.5 mol / L hydrochloric acid solution Neutral, filter, wash the filter cake with absolute ethanol, dry below 50°C, and pulverize to obtain octenyl succinic acid resistant starch ester;

[0029] B. Preparation of metal-organic framework materials: Dissolve 30 g of γ-cyclodextrin and 3.7 g of potas...

Embodiment 3

[0032] Example 3, Preparation of resistant starch nutritional carrier based on metal organic framework

[0033] The preparation method of the resistant starch nutrient carrier based on the metal organic framework comprises the following steps:

[0034] A. Preparation of octenyl succinic acid resistant starch ester: Stir 200g of resistant starch and 100mL of absolute ethanol in a high-speed mixer at 1500rpm to fully swell the resistant starch, then add 0.5 160 mL of anhydrous ethanol solution of g / mL octenyl succinic anhydride, adjust the pH to 10.5 with 0.5 mol / L sodium hydroxide solution, and heat the reaction in a water bath at 90°C for 8 hours; after the reaction, adjust the pH to 0.5 mol / L hydrochloric acid solution Neutral, filter, wash the filter cake with absolute ethanol, dry below 50°C, and pulverize to obtain octenyl succinic acid resistant starch ester;

[0035] B. Preparation of metal-organic framework materials: Dissolve 10 g of γ-cyclodextrin and 1.24 g of potas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com