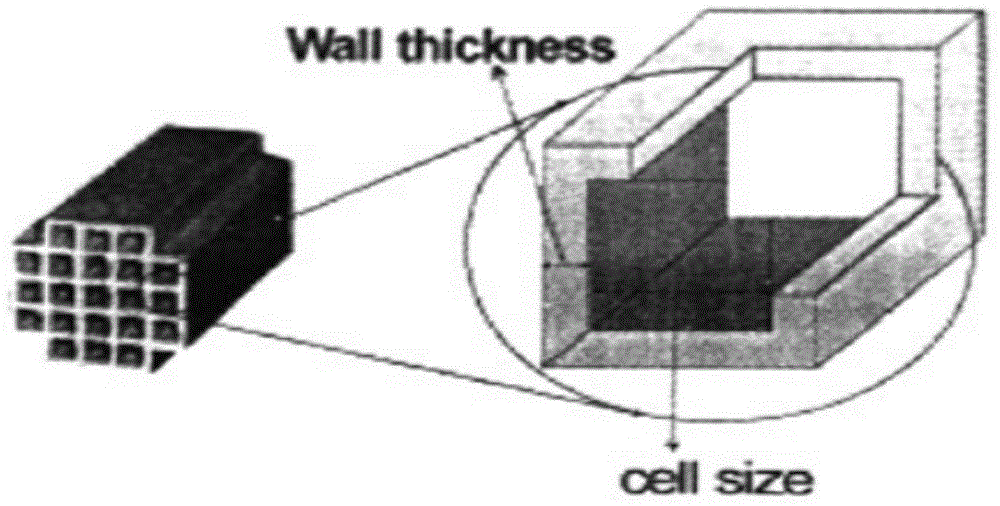

Porous graphite carbon composite material as well as preparation method and application thereof

A technology of porous graphite carbon and composite materials, which is applied in the field of porous graphite carbon composite materials and the preparation of porous graphite carbon composite materials, can solve the problems of inability to balance strength and carbon content, low overall performance, etc., and achieve good mechanical properties and raw materials. The effect of a wide range of sources and good heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The porous graphite carbon composite material of the present embodiment is made of the following raw materials in parts by weight: 75 parts of graphite, 13 parts of polystyrene cation exchange resin, 12 parts of pitch coke, and 100 parts of polyvinyl alcohol solution with a mass concentration of 15%. , 30 parts of coal tar pitch.

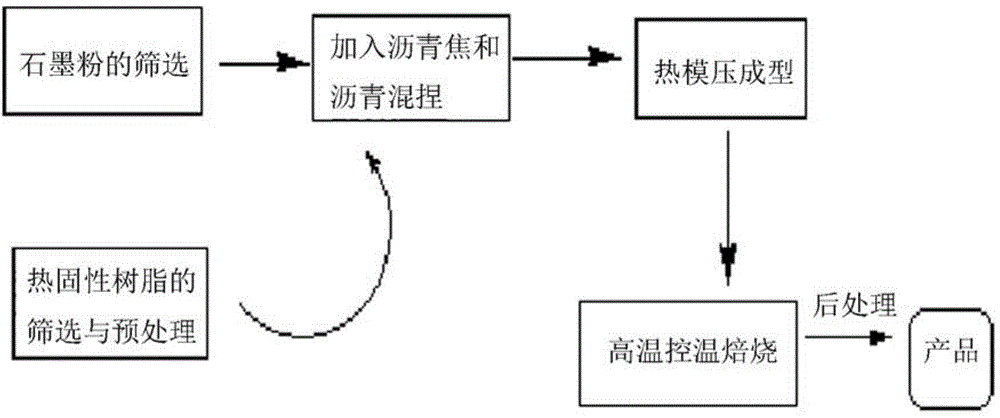

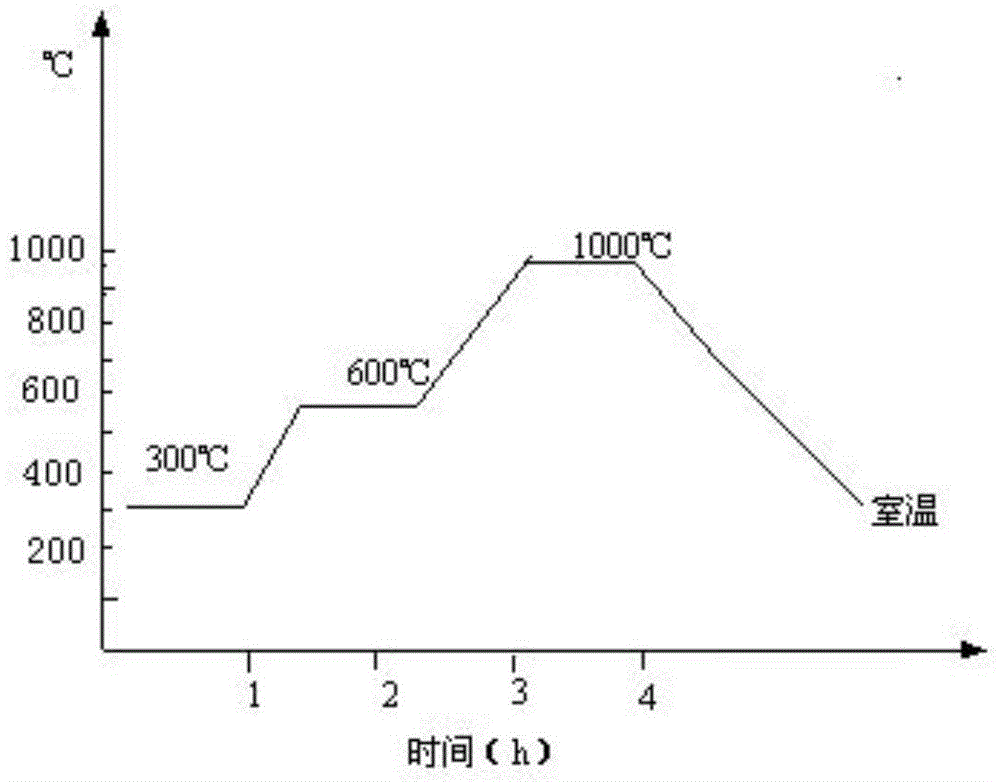

[0033] The preparation method of the porous graphite carbon composite material of the present embodiment, the flow chart is as follows figure 2 shown, including the following steps:

[0034] 1) Preprocessing:

[0035] Soak graphite powder in nitric acid with a concentration of 1mol / L for 0.5h, ultrasonically wash for 10min, filter and wash with water until neutral, dry in an oven at 110°C for 1h, and set aside;

[0036] Soak the polystyrene cation exchange resin in 1mol / L hydrochloric acid for 10 hours, wash it with water until neutral, dry it at 80°C, and set it aside;

[0037] Grind the pitch coke into powder and sieve through a 200-mes...

Embodiment 2

[0047] The porous graphite carbon composite material of the present embodiment is made of the following raw materials in parts by weight: 70 parts of graphite, 8 parts of phenolic resin, 10 parts of pitch coke, 120 parts of polyvinyl alcohol solution with a mass concentration of 10%, 20 parts of coal tar pitch share.

[0048] The preparation method of the porous graphite carbon composite material of the present embodiment comprises the following steps:

[0049] 1) Preprocessing:

[0050] Soak graphite powder in nitric acid with a concentration of 1mol / L for 0.5h, ultrasonically wash for 10min, filter and wash with water until neutral, dry in an oven at 110°C for 1h, and set aside;

[0051] Grind the pitch coke into powder and sieve through a 200-mesh sieve, then take the fine powder for later use;

[0052] 2) Take 70 parts by weight of graphite powder, 8 parts by weight of phenolic resin, and 10 parts by weight of pitch coke powder, mix and stir evenly, add 120 parts by weig...

experiment example

[0060] In this experimental example, the properties of the porous graphite carbon composite material obtained in Examples 1 and 2 were tested, and the results are shown in Table 1. Among them, the comparative example is activated carbon material (commercially available).

[0061] Table 1 Performance test results of the porous graphite carbon composite material obtained in Examples 1-2

[0062] project

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com