Method for preparing lightweight calcium hexaaluminate at low temperature

A light-weight calcium hexaaluminate technology, which is applied in the field of low-temperature preparation of light calcium hexaaluminate, can solve the problems of endangering the health of workers and the environment, hindering the popularization of calcium hexaaluminate, volatile corrosion or pollution of the furnace body, etc. , to achieve the effect of simple process, easy operation and lower sintering temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

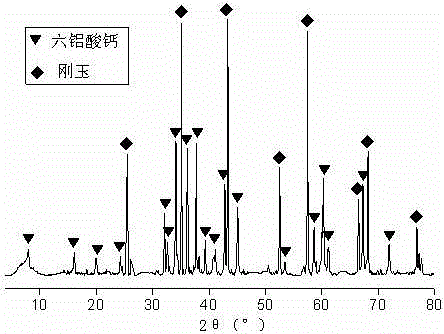

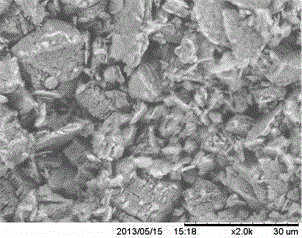

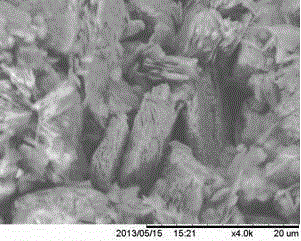

[0027] A method for preparing light calcium hexaaluminate at low temperature, according to CaO, Al 2 o 3 The molar ratio is 1:6 to weigh calcium hydroxide and aluminum hydroxide, the water consumption is 55 times that of calcium hydroxide, the consumption of glycerol and triethanolamine are respectively 25% and 10% of the water consumption, and the consumption of sodium hydroxide is hydrogen 2.6% of the amount of alumina. After mixing the raw materials evenly, place them in an autoclave at 150°C for 12 hours. After cooling, the solid-liquid separation is formed into balls. After drying, they are calcined in a high-temperature furnace at 1400°C for 3 hours, and then cooled to room temperature with the furnace to obtain the product. The apparent density of the product is 1290 Kg / m 3 , bulk density is 640 Kg / m 3 .

Embodiment 2

[0029] A method for preparing light calcium hexaaluminate at low temperature, according to CaO, Al 2 o 3 The molar ratio is 1:8 to weigh calcium hydroxide and aluminum hydroxide, the water consumption is 55 times that of calcium hydroxide, the consumption of glycerol and triethanolamine are respectively 25% and 10% of the water consumption, and the consumption of sodium hydroxide is hydrogen 0% of the amount of alumina used. After mixing the raw materials evenly, place them in an autoclave at 150°C for 12 hours. After cooling, the solid-liquid separation is formed into balls. After drying, they are calcined in a high-temperature furnace at 1400°C for 3 hours, and then cooled to room temperature with the furnace to obtain the product. The apparent density of the product is 1260 Kg / m 3 , bulk density is 680 Kg / m 3 .

Embodiment 3

[0031] A method for preparing light calcium hexaaluminate at low temperature, according to CaO, Al 2 o 3 The molar ratio is 1:8 to weigh calcium hydroxide and aluminum hydroxide, the water consumption is 55 times that of calcium hydroxide, the consumption of glycerol and triethanolamine are respectively 10% and 10% of the water consumption, and the consumption of sodium hydroxide is hydrogen 0% of the amount of alumina used. After mixing the raw materials evenly, place them in an autoclave at 150°C for 12 hours. After cooling, the solid-liquid separation is formed into balls. After drying, they are calcined in a high-temperature furnace at 1400°C for 3 hours, and then cooled to room temperature with the furnace to obtain the product. The apparent density of the product is 1250 Kg / m 3 , bulk density is 670 Kg / m 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com