Preparation method and using method of graded hole TiO2 ceramic photocatalyst

A photocatalyst and graded pore technology, used in ceramic products, chemical instruments and methods, catalysts for physical/chemical processes, etc., can solve the problems of inability to prepare and long time for the degradation of organic pollutants, and achieve the effect of shortening the degradation time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

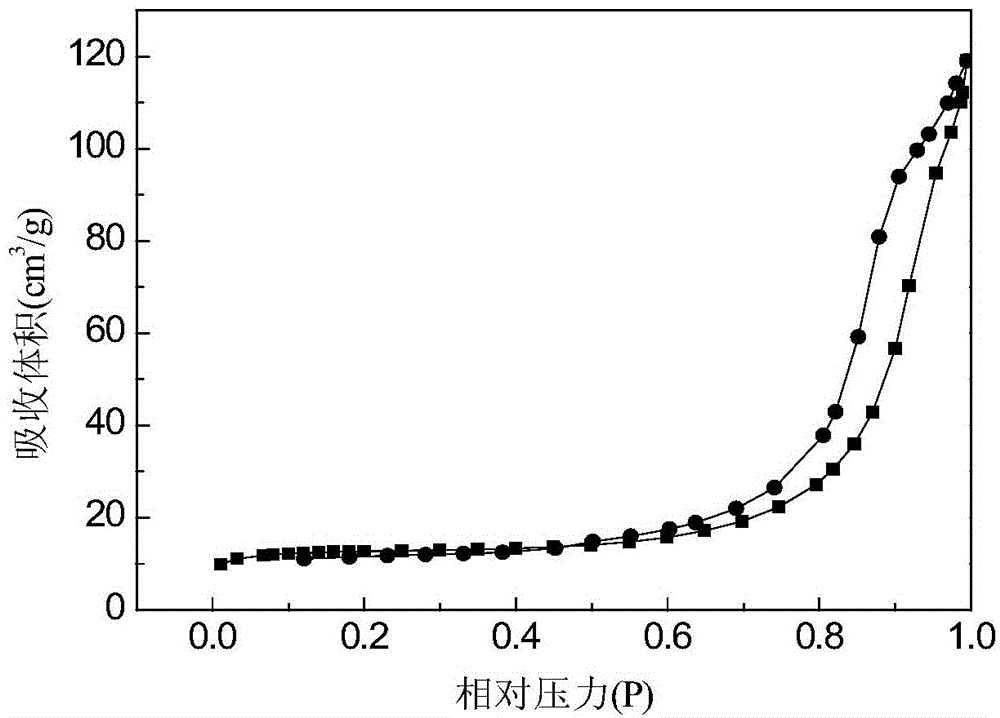

[0015] Specific implementation mode 1: In this implementation mode, a graded hole TiO 2 The preparation method of ceramic photocatalyst is carried out in the following steps:

[0016] 1. Mixing of reagents: Weigh 20 to 50 parts of high thermal stability mesoporous TiO according to the ratio of parts by mass 2 Powder material, 100-150 parts of deionized water, 10-15 parts of foaming agent, 2-5 parts of dispersant and 2-5 parts of binder, and then stir and mix the above-mentioned weighed reagents for 5-15 minutes to obtain Mixed reagent; 2. Ball milling: ball mill the mixed reagent prepared in step 1 at a temperature of 40°C to 80°C, and the ball milling time is 24h to 48h to obtain a slurry; 3. Injection molding: mix the slurry prepared in step 2 Put into the closed mold and place it in a constant temperature water bath at 80°C to 100°C for 1h to 2h to obtain the formed slurry; 4. Demoulding: separate the formed slurry obtained in step 3 from the mold to obtain the green body;...

specific Embodiment approach 2

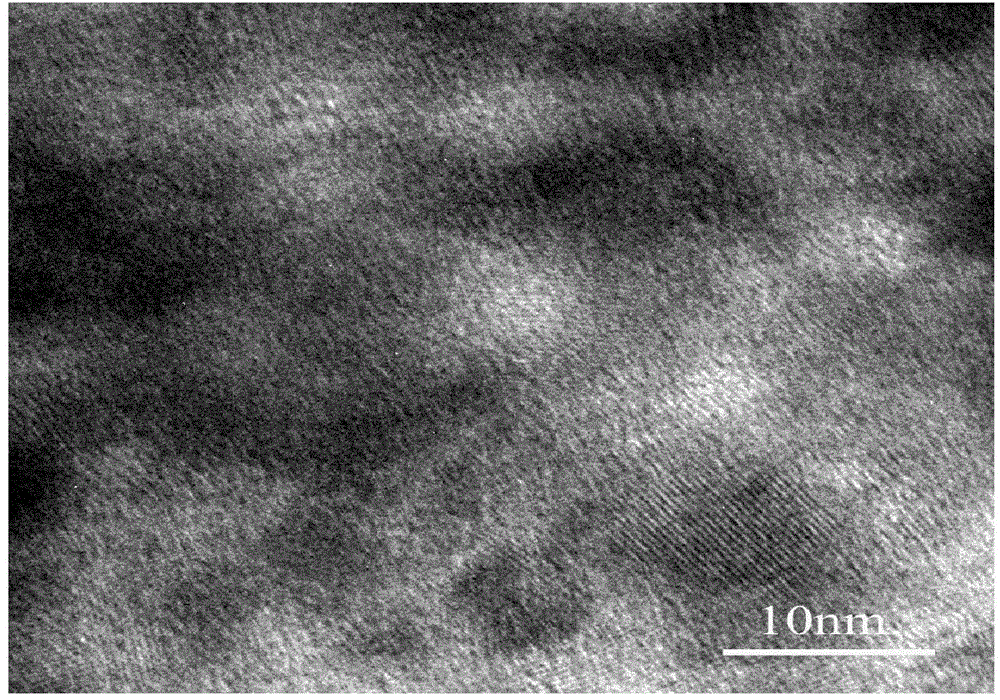

[0019] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the high thermal stability mesoporous TiO described in step one 2 The preparation method of powder material is carried out as follows: one, TiO 2 Preparation of sol: add 10mL of absolute ethanol to 10mL of tetrabutyl titanate and stir for 1h to form A solution; dissolve 0.5g of ammonium phosphate in 15mL of distilled water, add 30mL of absolute ethanol, add 3mL of nitric acid and stir for 30min to form B solution, and dissolve B The solution was dropped into solution A, stirred for 1 h, and heated in water at 160°C for 6 h. 2. SiO2 2 Preparation of sol: Dissolve 1g of P123 in 25g of distilled water, add 2g of hydrochloric acid, stir for 30min, then add 2.4g of tetraethyl orthosilicate, stir for 12h, then heat at 100°C for 12h. TiO obtained in step 1 2 Sol and SiO obtained in step 2 2 After the sol was mixed and stirred for 2 hours, it was dried in a drying oven at 60°C, t...

specific Embodiment approach 3

[0020] Specific embodiment 3: The difference between this embodiment and specific embodiment 1 or 2 is that in step 2, the reagents weighed above are stirred and mixed for 8 minutes. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com