Method for producing radiation-vulcanized ethylene propylene diene monomer flame-retardant automobile rubber tube

A technology of EPDM rubber and production method, which is applied in the direction of hoses, pipes, pipes/pipe joints/pipe fittings, etc., which can solve the problem of low compression deformation of rubber hoses, high temperature resistance, resistance to cooling liquid, and resistance to aging of rubber hoses Performance impact, automobile corrosion damage and other problems, to shorten the vulcanization time, improve the vulcanization effect, and improve the performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

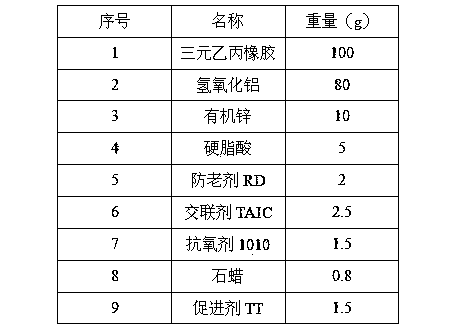

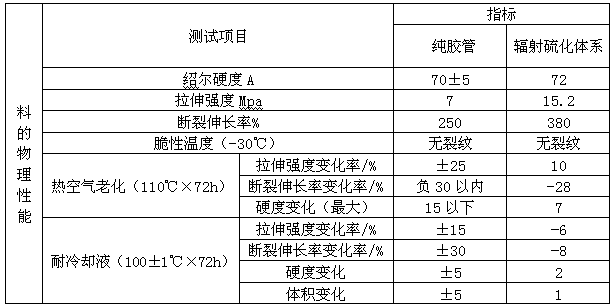

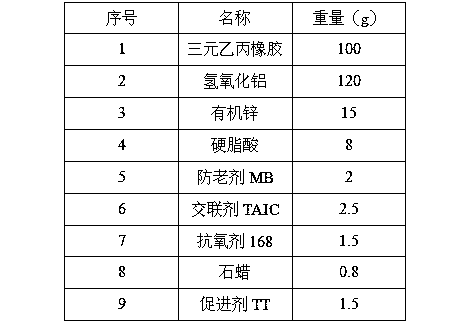

[0018] 1. The following are three formulation examples of crosslinking flame retardant EPDM hose formulations by electron beam irradiation:

[0019] Among them, EPDM rubber is EPDM rubber produced by Dow in the United States; aluminum hydroxide is surface-modified aluminum hydroxide with a particle size of 8000 meshes on the market; organic zinc is obtained by surface modification and grafting of zinc oxide. Organic zinc made on organic matter.

[0020] Self-made organic zinc process: adjust the temperature of the double-roll mill to 130°C, and masticate 100 parts by mass of butadiene rubber and styrene-butadiene rubber (1:4). Then add 50 parts by mass of pre-mixed zinc oxide, stearic acid, dibutyl phthalate and a small amount of accelerator DM, masticate for 10 minutes, discharge the material after the zinc oxide is uniformly dispersed, and granulate for later use. The organozinc prepared by the method has good binding force with the resin, and can be used as a reinforcing a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com