Method for treating cyaniding gold extraction waste liquid to recover gold, silver and copper by use of acid making waste gas

A technology for extracting gold waste liquid and acid waste gas, which is applied in waste gas treatment and environmental protection in the chemical industry, and in the field of gold smelting. It can solve the problems of environmental hazards, poor treatment effects, and high treatment costs, so as to reduce pollution hazards and eliminate treatment costs. High, improve the effect of economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

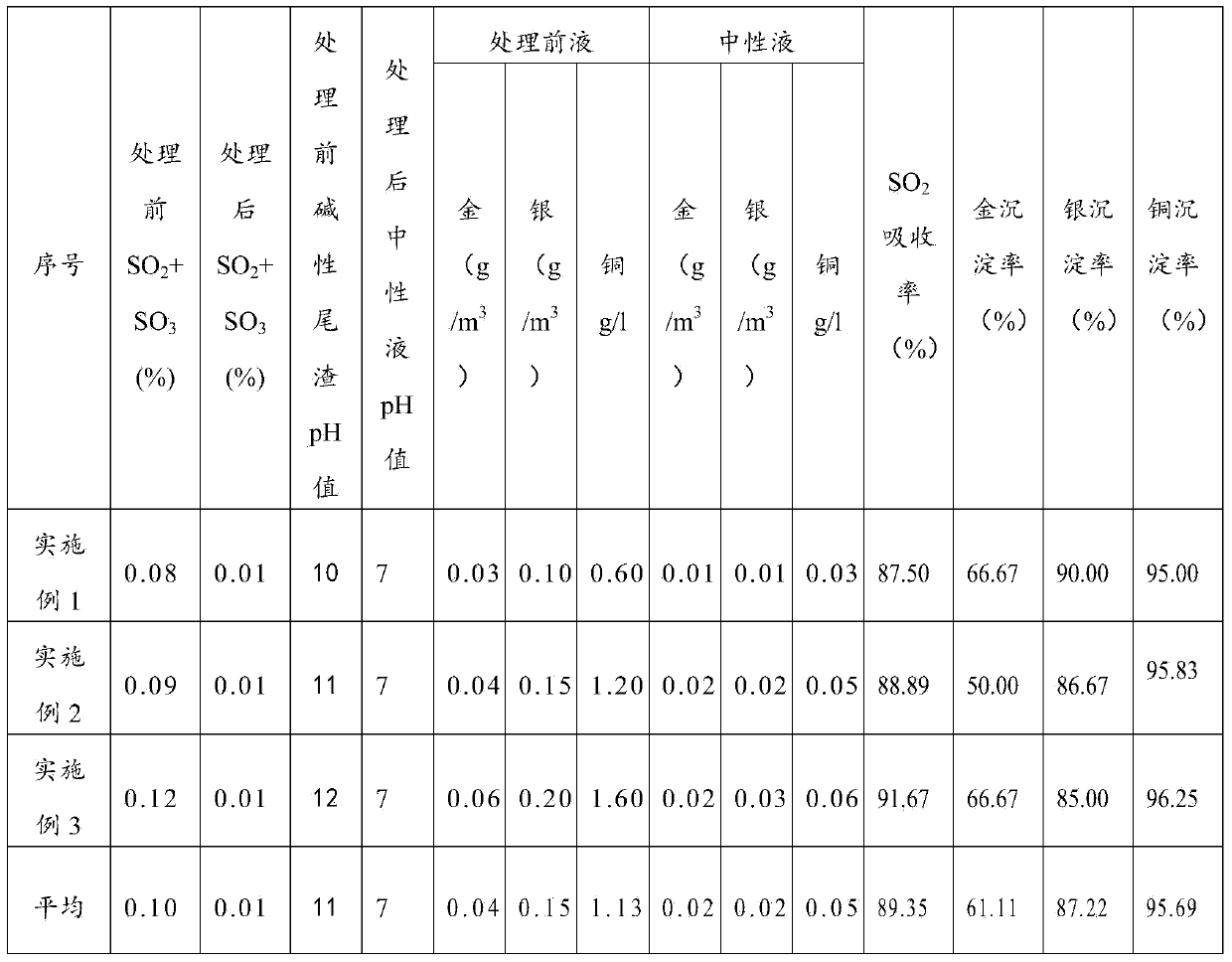

Embodiment 1

[0024] The first step, sulfur-containing mineral roasting

[0025] Configure 22% sulfur-containing minerals or polymetallic sulfide minerals into the roasting furnace, wherein the polymetallic sulfide minerals can include copper, zinc, gold, silver, etc., and roast to obtain roasting flue gas and calcined sand after roasting. The roasting flue gas is discharged from the flue of the roaster, and then enters the first-level cooling dust collector and the second-level cooling dust collector in turn, the roasting flue gas in the first-level cooling dust collector and the dust-containing smoke in the second-level cooling dust collector The gas is further purified and dedusted through electrostatic dedusting, washing, and electrostatic demisting, and the calcined sand after the roasting enters the corresponding extraction process;

[0026] The second step, acid production tail gas

[0027] After purification and dust removal of the output SO 2 Dried SO 2 , two conversions of SO ...

Embodiment 2

[0033] The first step, sulfur-containing mineral roasting

[0034] Configure 23% sulfur-containing minerals or polymetallic sulfide minerals into the roasting furnace, wherein the polymetallic sulfide minerals can include copper, zinc, gold, silver, etc., and roast to obtain roasting flue gas and calcined sand after roasting. The roasting flue gas is discharged from the flue of the roaster, and then enters the first-level cooling dust collector and the second-level cooling dust collector in turn, the roasting flue gas in the first-level cooling dust collector and the dust-containing smoke in the second-level cooling dust collector The gas is further purified and dust-removed through electric dust removal, washing, and electric defogging, and the roasted sand enters the corresponding extraction process.

[0035] The second step, acid production tail gas

[0036] After purification and dust removal of the output SO 2 Dried SO 2 , two conversions of SO 2 And secondary absorpt...

Embodiment 3

[0042] The first step, sulfur-containing mineral roasting

[0043] Configure 25% sulfur-containing minerals or polymetallic sulfide minerals into the roasting furnace, wherein the polymetallic sulfide minerals can include copper, zinc, gold, silver, etc., and roast to obtain roasting flue gas and calcined sand after roasting. The roasting flue gas is discharged from the flue of the roaster, and then enters the first-level cooling dust collector and the second-level cooling dust collector in turn, the roasting flue gas in the first-level cooling dust collector and the dust-containing smoke in the second-level cooling dust collector The gas is further purified and dust-removed through electric dust removal, washing, and electric defogging, and the roasted sand enters the corresponding extraction process.

[0044] The second step, acid production tail gas

[0045] After purification and dust removal of the output SO 2 Dried SO 2 , two conversions of SO 2 And secondary absorpt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com