Wire mesh made of reinforced fiber and stainless steel wire

A technology of reinforced fiber and stainless steel wire, which is used in mufflers, engine components, machines/engines, etc., can solve the problems of inability to adapt to the high temperature working conditions of automotive post-processors, insufficient turbulence, and high temperature resistance, and achieves high practicality. The effect of value, micro-performance improvement, reliability and stability improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

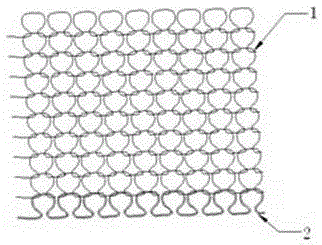

Image

Examples

Embodiment 1

[0025] Using 10 strands of 0.35mm FeCrAl stainless steel wire, weave a vapor-liquid filter on an industrial vapor-liquid filter weaving machine; after weaving, use tap water and alcohol as a solvent of 1:2, and ultrasonically immerse for 20 minutes at room temperature. Clean oil stains; rinse once with tap water; dry in an oven at 80°C for 1 hour; cut out a 60mm×220mm mesh, visually observe the'thickness' of the mesh is about 2mm, weigh W1=18.698g; put it in distilled water for 5 minutes, take it out, and pour Dry the excess water, weigh W2=19.652g, and calculate the water absorption rate of the carrier sheet according to the following formula R=(W2-W1) / W1=5.1%

Embodiment 2

[0027] Using 10 strands of 0.35mm FeCrAl stainless steel wire, one strand of stainless steel wire is paralleled with 1 strand of carbon fiber bundle. The carbon fiber bundle is a 1K carbon fiber bundle with a monofilament diameter of 5μm after phenolic strengthening treatment. On the vapor-liquid filter weaving machine, mix and crochet into a 10:1 hybrid wire mesh; after weaving, use a 1:2 solvent of tap water and alcohol, and at room temperature, ultrasonically immerse for 20 minutes to remove the resin binder; Rinse once with tap water; dry in an oven at 80°C for 3 hours; cut out 100mm×100mm mesh, visually measure the'thickness' of the mesh is about 5mm, weigh W1=24.844g, put it in distilled water for 5 minutes, take it out, and dry the excess Water, weighed W2=33.953g, the water absorption rate of the carrier sheet R=(W2-W1) / W1=36.67%

Embodiment 3

[0029] 10 strands of 0.35mm FeCrAl stainless steel wire with a diameter of 0.35mm are used. One strand of carbon fiber bundle is used in each stainless steel wire, a total of 10 strands. The carbon fiber bundle is a 1K carbon fiber bundle with a monofilament diameter of 20μm after phenolic strengthening treatment. The industrial vapor-liquid filter screen knitting machine is mixed and crocheted into a 1:1 hybrid wire mesh; after weaving, use tap water and alcohol as a 1:2 solvent, at room temperature, ultrasonic immersion for 30 minutes to remove resin bonding Rinse once with tap water; dry in an oven at 80℃ for 3h; cut out a 100mm×100mm mesh, visually observe that the'thickness' of the mesh is greater than 5mm, weigh W1=38.958g, put it in distilled water for 5 minutes, take it out, and dry the excess Water, weighing W2=107.888g, the water absorption rate of the carrier sheet R=(W2-W1) / W1=176.9%

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com