POSS (Polyhedral Oligomeric Silsesquioxane) crosslinking type sulfonated polyimide proton exchange membrane as well as preparation method thereof

A technology of sulfonated polyimide and proton exchange membrane, which is applied in the field of functional polymer materials and electrochemistry, and can solve proton conduction hindrance, poor stability against free radical oxidation, and low proton conductivity of sulfonated polybenzimidazole membrane And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

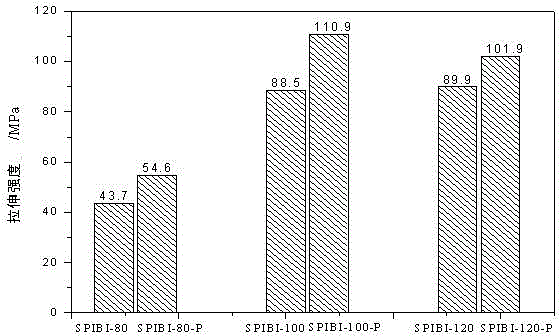

Image

Examples

Embodiment 1

[0032] The ratio of raw materials used is as follows:

[0033] 1 part of SPIBI-100 (number of moles of repeating units)

[0034] Octaepoxy polyhedral oligomeric silsesquioxane (POSS) 0.025 parts (accounting for the mass number of SPIBI-100)

[0035] Dimethylsulfoxide 160 parts (moles)

[0036] (1) Soak 0.6g SPIBI-100 in saturated NaCl solution, take it out and dry it after 24 hours. Then dissolved in 13 mL of dimethyl sulfoxide (DMSO) at 100 °C to form a homogeneous solution.

[0037] (2) Dissolve 0.015g octaepoxy-substituted POSS in 1mL DMSO solution at room temperature, and stir until a homogeneous solution. Mix well with the solution formed in (1) at room temperature, and filter to remove air bubbles.

[0038] (3) The mixture obtained in step (2) was poured on a 10 cm×10 cm glass plate, and dried in a vacuum oven at 80 °C for 6 h, and the solvent was completely evaporated. Raise the temperature to 150 °C and continue heating for 10 h to complete the cross-linking react...

Embodiment 2

[0043] The ratio of raw materials used is as follows:

[0044] 1 part of SPIBI-10 (number of moles of repeating units)

[0045] 0.15 parts of octaepoxy polyhedral oligomeric silsesquioxane (POSS) (accounting for the mass number of SPIBI-10)

[0046]400 parts of dimethyl sulfoxide (number of moles)

[0047] (1) Soak 0.6g SPIBI-100 in saturated NaCl solution, take it out and dry it after 24 hours. Then dissolved in 30 mL dimethyl sulfoxide (DMSO) at 100 °C to form a homogeneous solution.

[0048] (2) Dissolve 0.015g octaepoxy-substituted POSS in 4mL DMSO solution at room temperature, and stir until a homogeneous solution is obtained. Mix well with the solution formed in (1) at room temperature, and filter to remove air bubbles.

[0049] (3) The mixture obtained in step (2) was poured on a 10 cm×10 cm glass plate, and dried in a vacuum oven at 80 °C for 6 h, and the solvent was completely evaporated. Raise the temperature to 150°C and continue heating for 12 hours to complet...

Embodiment 3

[0052] The ratio of raw materials used is as follows:

[0053] 1 part of SPIBI-190 (number of moles of repeating unit)

[0054] Octaepoxy polyhedral oligomeric silsesquioxane (POSS) 0.50 parts (mass ratio to SPIBI-190)

[0055] N-Methylpyrrolidone (NMP) 500 parts (moles)

[0056] (1) Soak 0.6g SPIBI-190 in saturated NaCl solution, take it out and dry it after 24 hours. Then dissolve in 30 mL of N-methylpyrrolidone (NMP) at 100 °C to form a homogeneous solution.

[0057] (2) Dissolve 0.3g of octaepoxy-substituted POSS in 10mL of NMP solution at room temperature, and stir until a homogeneous solution is obtained. Mix well with the solution formed in (1) at room temperature, and filter to remove air bubbles.

[0058] (3) The mixture obtained in step (2) was poured on a 10 cm×10 cm glass plate, and dried in a vacuum oven at 80 °C for 6 h, and the solvent was completely evaporated. Raise the temperature to 150°C and continue heating for 8 hours to complete the crosslinking rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com