Preparation method for zinc oxide/stannic oxide composite microsphere

A technology of tin dioxide and composite microspheres, applied in the directions of zinc oxide/zinc hydroxide, microsphere preparation, tin oxide, etc., can solve the problems of poor selectivity, lack of synthesis methods, etc., and achieve easy components and sizes, and simple methods. , the effect of uniform particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

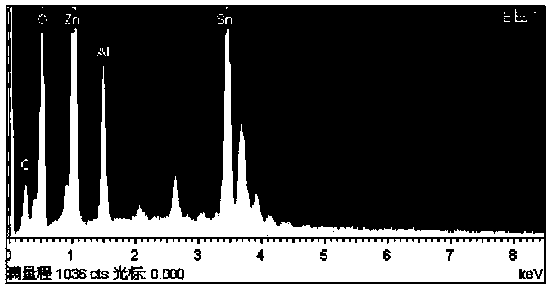

Image

Examples

Embodiment 1

[0024] ZnO / SnO 2 Preparation of composite precursor solution:

[0025] Weigh 2.1 g of triblock copolymer polyoxyethylene-polyoxypropylene-polyoxyethylene (P123), dissolve the block polymer in absolute ethanol, stir, and after P123 is completely dissolved, add 0.2 g of stannous chloride water, stirred at room temperature for 3 hours; then weighed 0.9 g of zinc acetate dihydrate, stirred at room temperature for 3 hours.

[0026] ZnO / SnO 2 Preparation of composite microspheres:

[0027] The prepared ZnO / SnO 2 The composite precursor solution was placed in a polytetrafluoroethylene autoclave, reacted at 180°C for 24 hours, and cooled naturally to room temperature. Filtered, washed with absolute ethanol and deionized water several times, dried at 60 °C, and fully ground to obtain the final product ZnO / SnO 2 Composite microspheres.

Embodiment 2

[0029] ZnO / SnO 2 Preparation of composite precursor solution:

[0030] Weigh 2.1 g of triblock copolymer polyoxyethylene-polyoxypropylene-polyoxyethylene (P123), dissolve the block polymer in absolute ethanol, stir, and after P123 is completely dissolved, add 0.2 g of stannous chloride water, stirred at room temperature for 3 hours; then weighed 0.9 g of zinc acetate dihydrate, stirred at room temperature for 3 hours.

[0031] ZnO / SnO 2 Preparation of composite microspheres:

[0032] The prepared ZnO / SnO 2 The composite precursor solution was placed in a polytetrafluoroethylene autoclave, reacted at 200°C for 24 hours, and cooled naturally to room temperature. Filtered, washed with absolute ethanol and deionized water several times, dried at 60 °C, and fully ground to obtain the final product ZnO / SnO 2 Composite microspheres.

Embodiment 3

[0034] ZnO / SnO 2 Preparation of composite precursor solution:

[0035] Weigh 2.1 g of triblock copolymer polyoxyethylene-polyoxypropylene-polyoxyethylene (P123), dissolve the block polymer in absolute ethanol, stir, and after P123 is completely dissolved, add 0.1 g of stannous chloride water, stirred at room temperature for 3 hours; then weighed 0.45 g of zinc acetate dihydrate, stirred at room temperature for 3 hours.

[0036] ZnO / SnO 2 Preparation of composite microspheres:

[0037] The prepared ZnO / SnO 2 The composite precursor solution was placed in a polytetrafluoroethylene autoclave, reacted at 120°C for 24 hours, and cooled naturally to room temperature. Filtered, washed with absolute ethanol and deionized water several times, dried at 80 °C, and fully ground to obtain the final product ZnO / SnO 2 Composite microspheres.

[0038] Example 3:

[0039] ZnO / SnO 2 Preparation of composite precursor solution:

[0040] Weigh 2.1 g of triblock copolymer polyoxyethylene-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com