Preparation method of Nb3Al superconducting material

A technology of superconducting material and solid solution is applied in the field of preparation of Nb3Al superconducting material, which can solve the problems of low Al content and grain growth, and achieve the effects of low cost, small grain size and simple preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

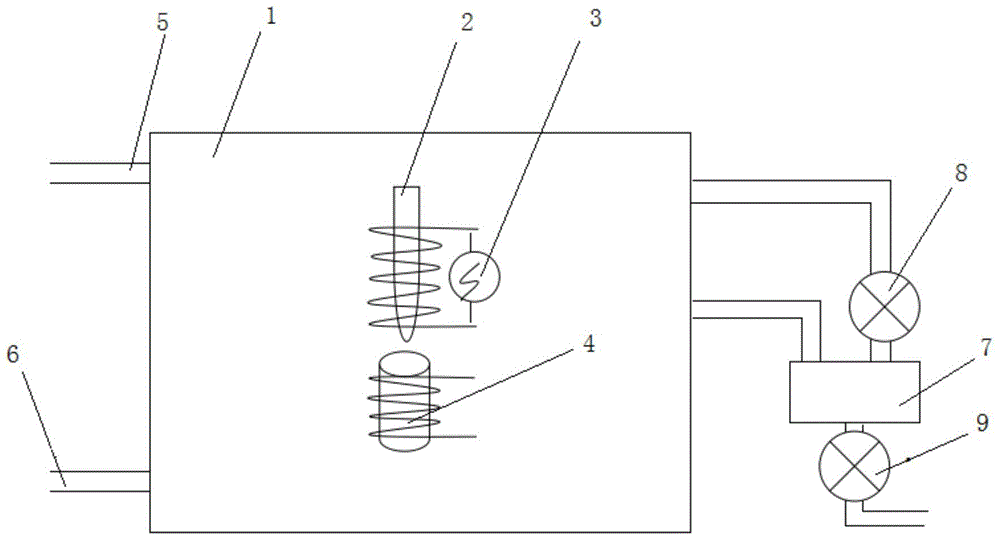

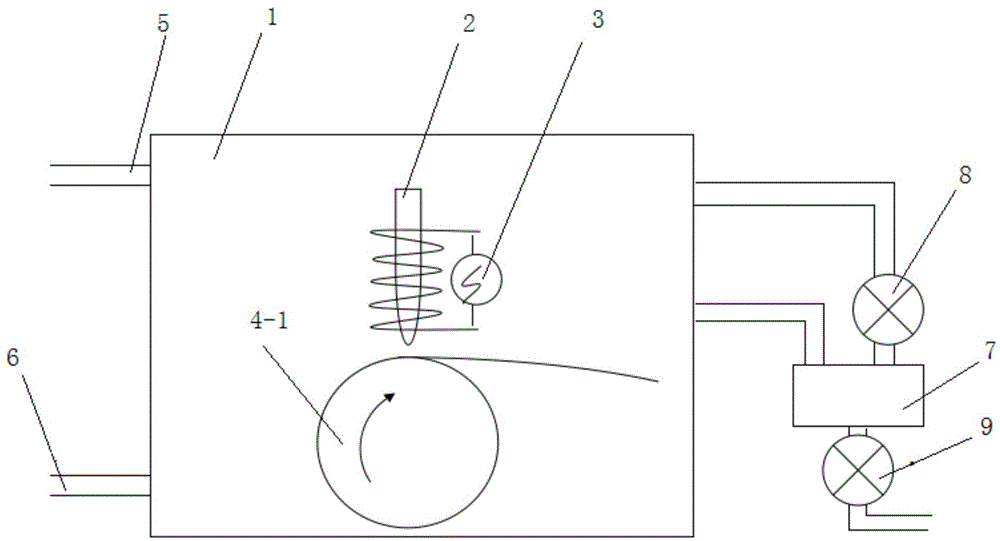

[0023] In the first step, take Nb powder with a purity of 99.99% and Al powder with a purity of 99.99%, mix it according to the ratio of Nb and Al atomic ratio of 3:1, weigh 5g of the uniformly mixed powder and place it in a boron nitride crucible, Install a water-cooled copper casting mold on the lower part of the crucible, and then vacuumize the vacuum chamber of the strip machine to 10 -3 Pa, and then fill the cavity with argon to normal pressure. See belt spinner figure 1 , including a vacuum chamber 1, a crucible 2 and a water-cooled copper mold 4 are arranged in the vacuum chamber 1, the crucible 2 has a power supply 3, the vacuum chamber 1 is connected with the intake pipe 5, the exhaust pipe 6, and the two-way pipe 7, and the two-way pipe 7 is connected with the The molecular pump 8 and the mechanical pump 9 are connected.

[0024] The second step is to turn on the power supply, control the heating temperature of the induction coil to 2450°C, keep it for 20 minutes t...

Embodiment 2

[0028] In the first step, take Nb powder with a purity of 99.99% and Al powder with a purity of 99.99%, mix it according to the ratio of Nb and Al atomic ratio of 3:1, weigh 2 g of the powder evenly mixed and place it in a boron nitride crucible, Install a water-cooled copper casting mold on the lower part of the crucible, and then vacuumize the vacuum chamber of the strip machine to 10 -4 Pa, then fill the chamber with argon to normal pressure, refer to figure 1 ;

[0029] The second step is to turn on the power supply, control the heating temperature of the induction coil to 2450°C, keep it for 20 minutes to make Nb and Al form a liquid phase, then cool down to 1950°C at a rate of 50°C / h, and keep it for 30 minutes to form a solid-liquid coexistence phase, and then Quickly fill the crucible cavity with high-purity argon, and use the pressure to spray the melt into the mold through the nozzle at the bottom of the crucible to obtain supersaturated solid solution Nb(Al)ss;

...

Embodiment 3

[0033] In the first step, take Nb powder with a purity of 99.99% and Al powder with a purity of 99.99%, mix it according to the ratio of Nb and Al atomic ratio of 3:1, weigh 8g of powder mixed uniformly and place it in a boron nitride crucible, Install a water-cooled copper casting mold on the lower part of the crucible, and then vacuumize the vacuum chamber of the strip machine to 10 -5 Pa, then fill the chamber with argon to normal pressure, refer to figure 1 ;

[0034] The second step is to turn on the power supply, control the heating temperature of the induction coil to 2450°C, keep it for 20 minutes to make Nb and Al form a liquid phase, then cool down to 2040°C at a rate of 50°C / h, and keep it for 30 minutes to form a solid-liquid coexistence phase, and then Quickly fill the crucible cavity with high-purity argon, and use the pressure to spray the melt into the water-cooled copper mold through the nozzle at the bottom of the crucible to obtain supersaturated solid solu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| superconducting critical temperature | aaaaa | aaaaa |

| superconducting critical temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com