Preparation method for mesoporous silica material

A technology of mesoporous silica and alkali metal silicate, applied in the direction of silica, silica, etc., can solve the problems of energy consumption, pollutant discharge, uneven distribution, long production cycle, etc., and shorten the preparation time , reduce production costs, and improve the effect of industrialization value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0011] First, the present invention provides a method for preparing a mesoporous silica material, wherein the method includes: (1) contacting an aqueous solution of an alkali metal silicate with a weakly acidic cation exchange resin under hydrolysis conditions to obtain a silica sol; (2) In the presence of a template agent, the obtained silica sol is subjected to microwave irradiation to produce mesoporous silica raw powder; (3) The product obtained by microwave irradiation is subjected to solid-liquid separation to remove the obtained mesoporous silica Templating agent in raw powder.

[0012] In the method of the present invention, the weakly acidic cation exchange resin can exchange metal cations such as alkali metal cations in the ionic state in the aqueous solution for H by contacting with an aqueous solution of an alkali metal silicate. + .

[0013] In the method of the present invention, theoretically as long as the amount of the weakly acidic cation exchange resin can ...

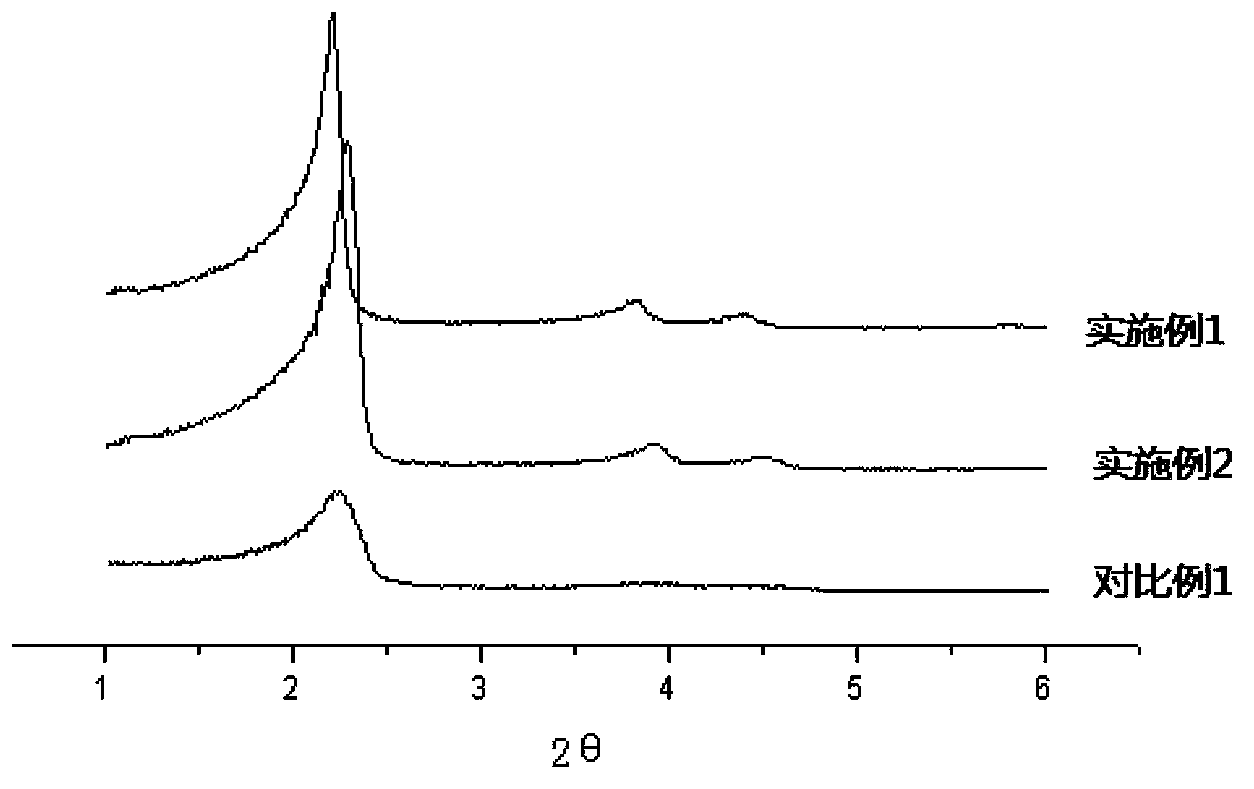

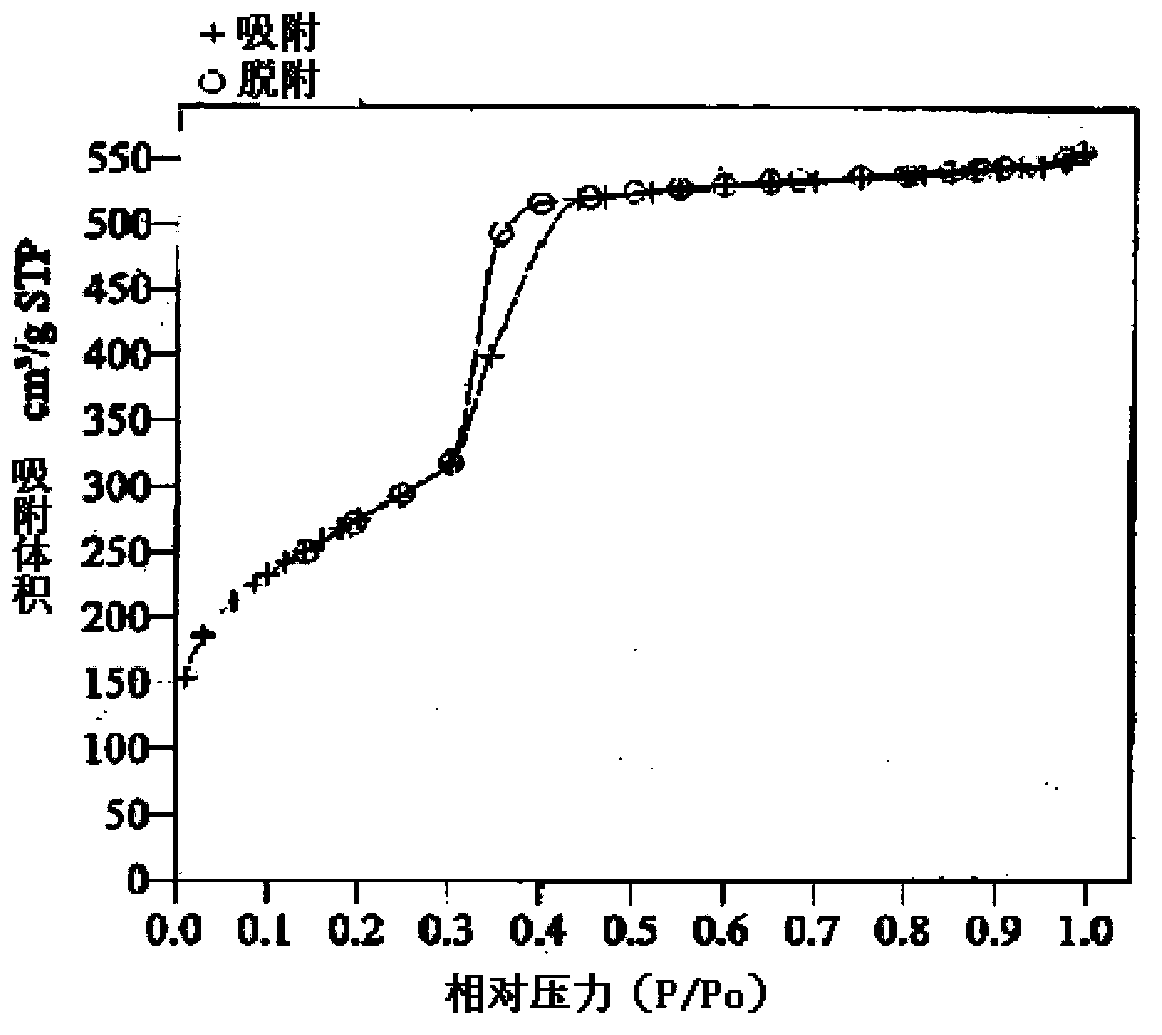

Embodiment 1

[0035] (1) Dissolve 260g of sodium silicate with a modulus of 3.6 in 140g of deionized water at 90°C to obtain an aqueous solution of sodium silicate. Under stirring, add 200g of weakly acidic cation exchange resin to the aqueous solution of sodium silicate in 16 times D113 (manufactured by Tianjin Nanda Resin Technology Co., Ltd., with a total exchange capacity of 10mmol / g), add the weakly acidic cation exchange resin for the last time and then continue to stir for 5 minutes (at this time, it is 80 minutes before adding the weakly acidic cation exchange resin), The weakly acidic cation exchange resin is removed by filtration to obtain a silica sol, and the particle diameter of the colloidal particles in the silica sol measured by a laser particle size analyzer is 15-20 nm.

[0036] (2) Add 13g of cetyltrimethylammonium bromide to the silica sol obtained in step (1) under stirring, and put the mixture into a microwave oven. Set the power of the microwave oven to 250W and the ti...

Embodiment 2

[0040] (1) Dissolve 200g of sodium silicate with a modulus of 3.4 in 240g of deionized water at 75°C to obtain an aqueous solution of sodium silicate. Under stirring, add 210g of weakly acidic cation exchange resin to the aqueous solution of sodium silicate for 10 times D114 (manufactured by Tianjin Nanda Resin Technology Co., Ltd., with a total exchange capacity of 8mmol / g), add the weakly acidic cation exchange resin for the last time and then continue to stir for 10 minutes (at this time, it is 70 minutes before adding the weakly acidic cation exchange resin), The weakly acidic cation exchange resin is removed by filtration to obtain a silica sol, and the particle diameter of the colloidal particles in the silica sol measured by a laser particle size analyzer is 15-25 nm.

[0041] (2) Under stirring, add 5g of P123 to the silica sol obtained in step (1), and put the mixture into a microwave oven at the same time, set the power of the microwave oven to 400W and the time to 0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Particle size range | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com