Cigarette filter tip and manufacturing method thereof

A filter tip and cigarette technology, applied in e-liquid filter, tobacco, application and other directions, can solve the problems of excessive pore closed-cell structure, need to improve the use effect, complex processing technology system, etc. The effect of strong material ability and low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

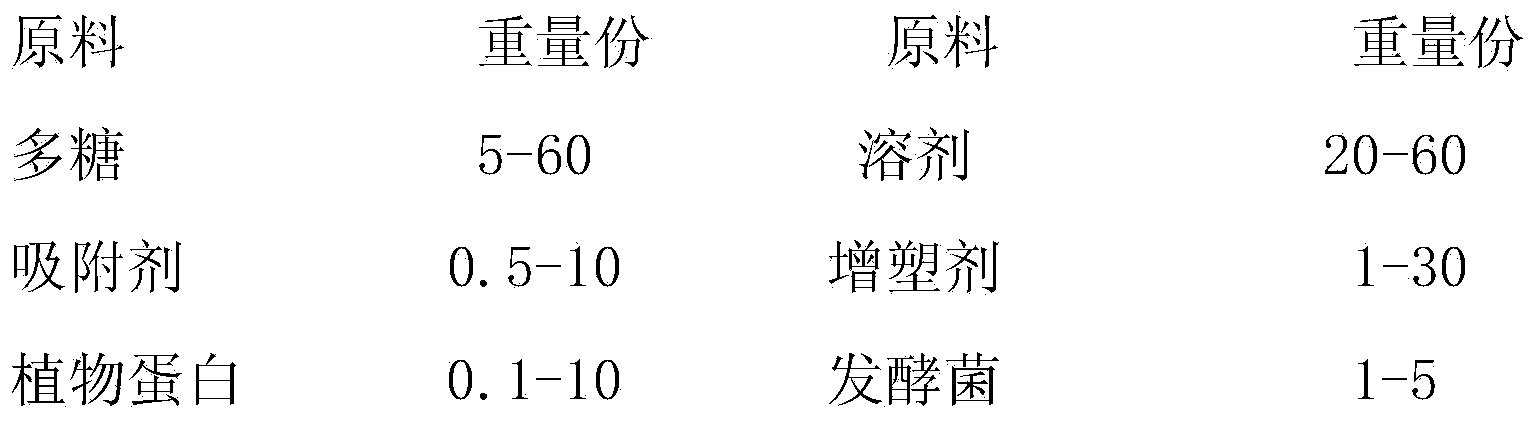

[0032] The present invention is prepared by the raw material of following weight portion:

[0033]

[0034] The preparation method of the present invention comprises the following steps:

[0035] 1. Dissolve dry yeast powder in water according to the above ratio;

[0036] 2. Mix starch, carrageenan, konjac glucomannan, hydroxypropyl methylcellulose, activated carbon, glycerin, and soybean protein according to the above ratio, and then add the aqueous solution of yeast. ℃) at a speed of 100rpm for 10min to form a mass to obtain a pre-fermented product;

[0037] 3. Put the pre-fermented product mixed evenly into agglomerates in step 2 into a constant temperature and humidity box at 28°C and 80% humidity to ferment for 40 minutes;

[0038] 4. Feed the material fermented in step 3 into the twin-screw extrusion puffing machine, control the feeding section, melting section, and puffing heating temperature, fully puff it, and get the cigarette filter after setting the shape. The...

Embodiment 2

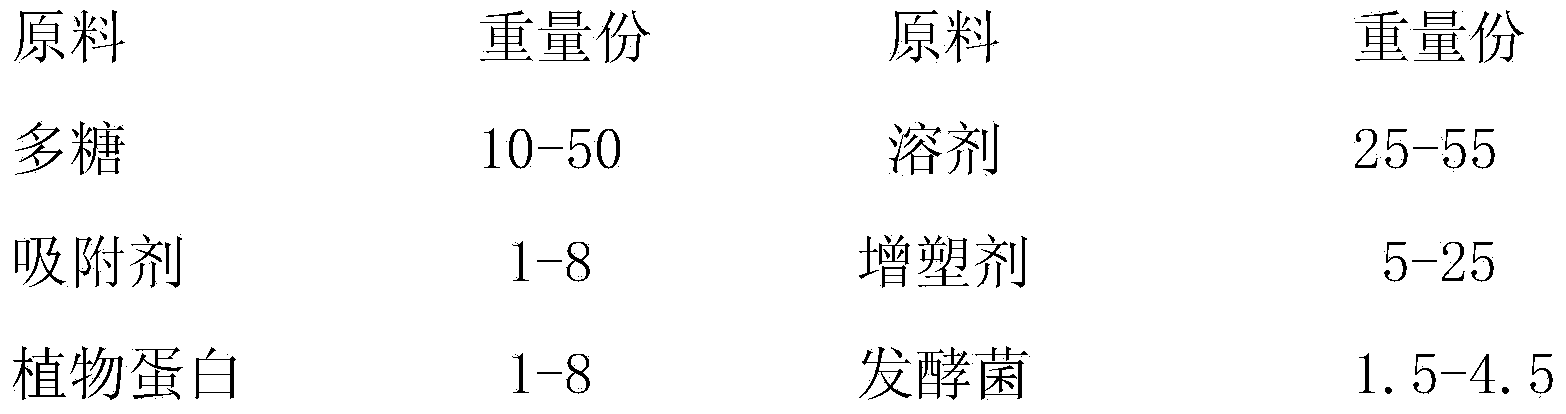

[0040] The present invention is prepared by the raw material of following weight portion:

[0041]

[0042] The preparation method of the present invention comprises the following steps:

[0043] 1. Dissolve dry yeast powder in water according to the above ratio;

[0044]2. Mix starch, carrageenan, konjac glucomannan, hydroxypropyl methylcellulose, activated carbon, glycerin, and soybean protein according to the above ratio, and then add the aqueous solution of yeast. ℃) at a speed of 100rpm for 10min to form a mass to obtain a pre-fermented product;

[0045] 3. Put the pre-fermented product mixed evenly into agglomerates in step 2 into a constant temperature and humidity box at 28°C and 80% humidity to ferment for 40 minutes;

[0046] 4. Feed the material fermented in step 3 into the twin-screw extrusion puffing machine, control the feeding section, melting section, and puffing heating temperature, fully puff it, and get the cigarette filter after setting the shape. The ...

Embodiment 3

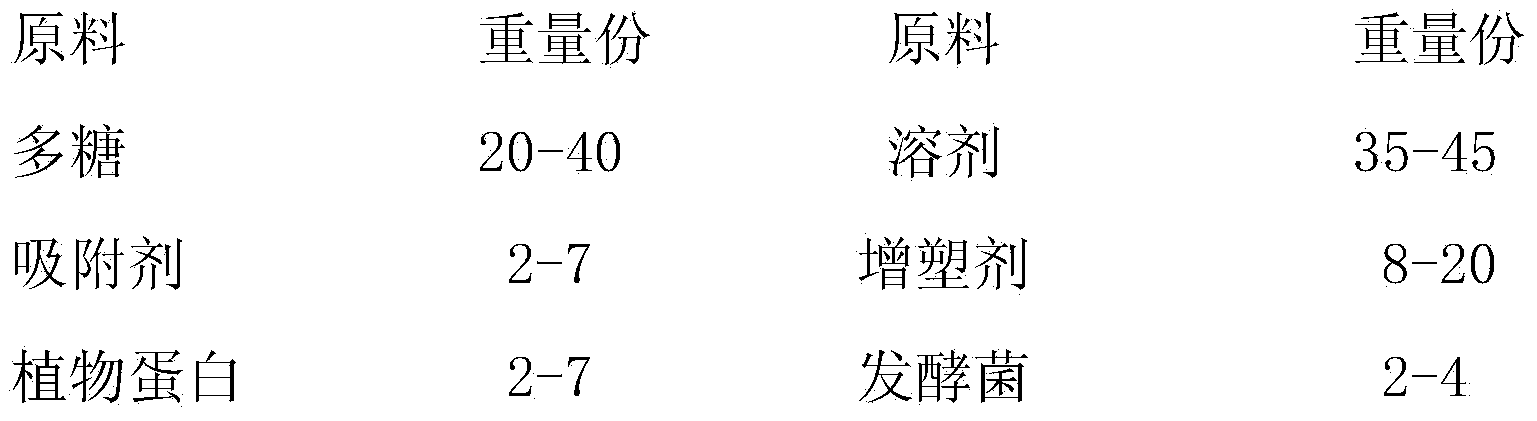

[0048] The present invention is prepared by the raw material of following weight portion:

[0049]

[0050] Its preparation steps are identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com