Polysilazane coating solution and method for preparing composite coating containing metallic oxide-SiO2

A polysilazane, metal compound technology, applied in the field of materials, achieves the effects of good chemical stability, low equipment requirements, and good light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

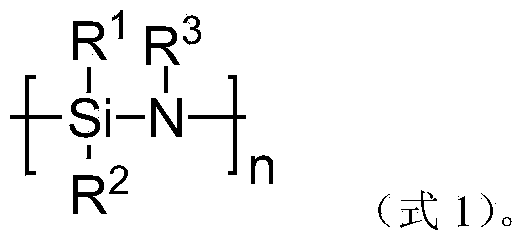

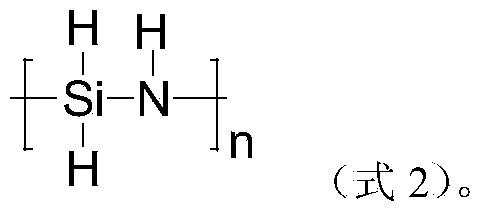

[0060] Embodiment 1: Preparation of inorganic polysilazane

[0061] 3000ml three-necked bottle, equipped with mechanical stirring, ultra-low temperature condenser, ammonia gas inlet tube and condenser tube. Vacuum through high-purity nitrogen three times, add 1800ml of dichloromethane, then lower the whole system to -30°C, add about 1000g of H 2 SiCl 2 Afterwards, ammonia gas is passed slowly for ammonolysis until the ammonia gas is no longer absorbed (there is a bubbling gas behind the reaction device, if the ammonia gas is no longer absorbed, the ammonia gas passed through will escape through the bubbler), so as to reduce the amount of ammonia gas Speed, continue to flow for 2h, stop the reaction, filter to remove ammonium chloride, and wash 3 times with the solvent dichloromethane, remove the solvent and oligomers by decompression, and obtain a colorless transparent liquid that is inorganic polysilazane, producing The ratio is about 70%, and the number average molecular w...

Embodiment 2

[0062] Embodiment 2: Preparation of inorganic polysilazane

[0063] 3000ml three-necked bottle, equipped with mechanical stirring, ultra-low temperature condenser, ammonia gas inlet tube and condenser tube. Vacuum through high-purity nitrogen three times, add 1800ml of dichloromethane, then lower the whole system to -30°C, add about 1000g of HSiCl 3 Afterwards, ammonia gas is passed slowly for ammonolysis until the ammonia gas is no longer absorbed (there is a bubbling gas behind the reaction device, if the ammonia gas is no longer absorbed, the ammonia gas passed through will escape through the bubbler), so as to reduce the amount of ammonia gas Speed, continue to pass for 2 hours, stop the reaction, filter to remove ammonium chloride, and wash with the solvent dichloromethane 3 times, remove the solvent and oligomers by decompression, and obtain a colorless transparent liquid that is inorganic polysilazane. The yield is about 70%, and the number average molecular weight of ...

Embodiment 3

[0064] Embodiment 3 prepares organopolysilazane

[0065] 3000ml three-necked bottle, equipped with mechanical stirring, ultra-low temperature condenser, ammonia gas inlet tube and condenser tube. Vacuum through high-purity nitrogen three times, add 1800ml of dichloromethane, then lower the whole system to -30°C, add about 1000g of CH 3 SiHCl 2 Afterwards, ammonia gas is passed slowly for ammonolysis until the ammonia gas is no longer absorbed (there is a bubbling gas behind the reaction device, if the ammonia gas is no longer absorbed, the ammonia gas passed through will escape through the bubbler), so as to reduce the amount of ammonia gas Speed, continue to flow for 2h, that is, stop the reaction, filter to remove ammonium chloride, and wash 3 times with solvent dichloromethane, remove solvent and oligomers by decompression method, and obtain a colorless transparent liquid that is organopolysilazane, wherein R1 is methyl, and both R2 and R3 are H. The yield is about 70%, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com