Pneumatic self-circulation animal cell culture bioreactor and application method thereof

A technology of animal cell culture and bioreactor, applied in the direction of bioreactor/fermenter combination, specific-purpose bioreactor/fermenter, biochemical equipment and methods, etc., can solve the problem of uneven mixing of large tank liquid, cell Cultivate problems such as low pollution rate and affecting product yield, so as to avoid flaws and defects, simplify pipeline layout, and solve the problem of heating overcharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

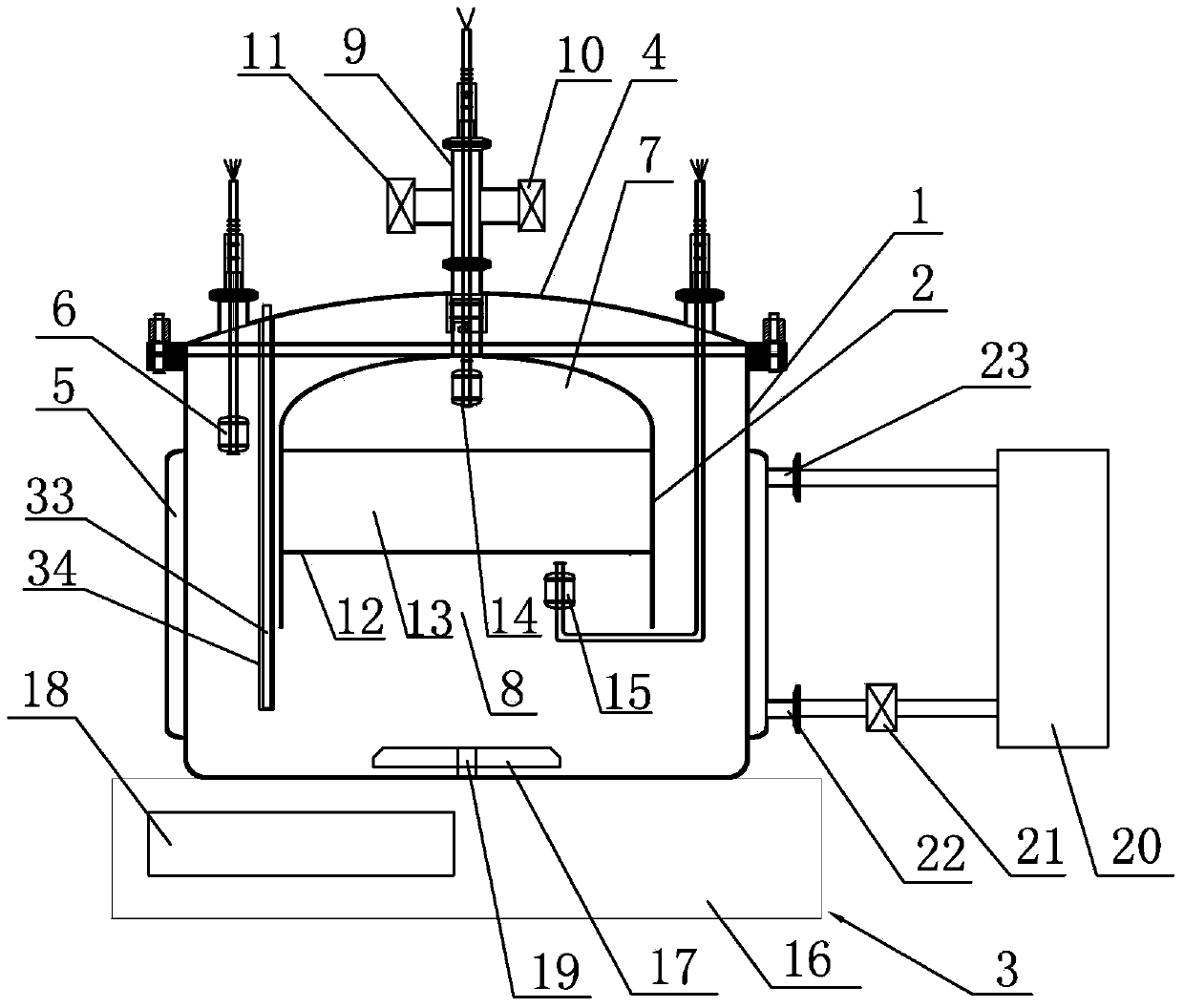

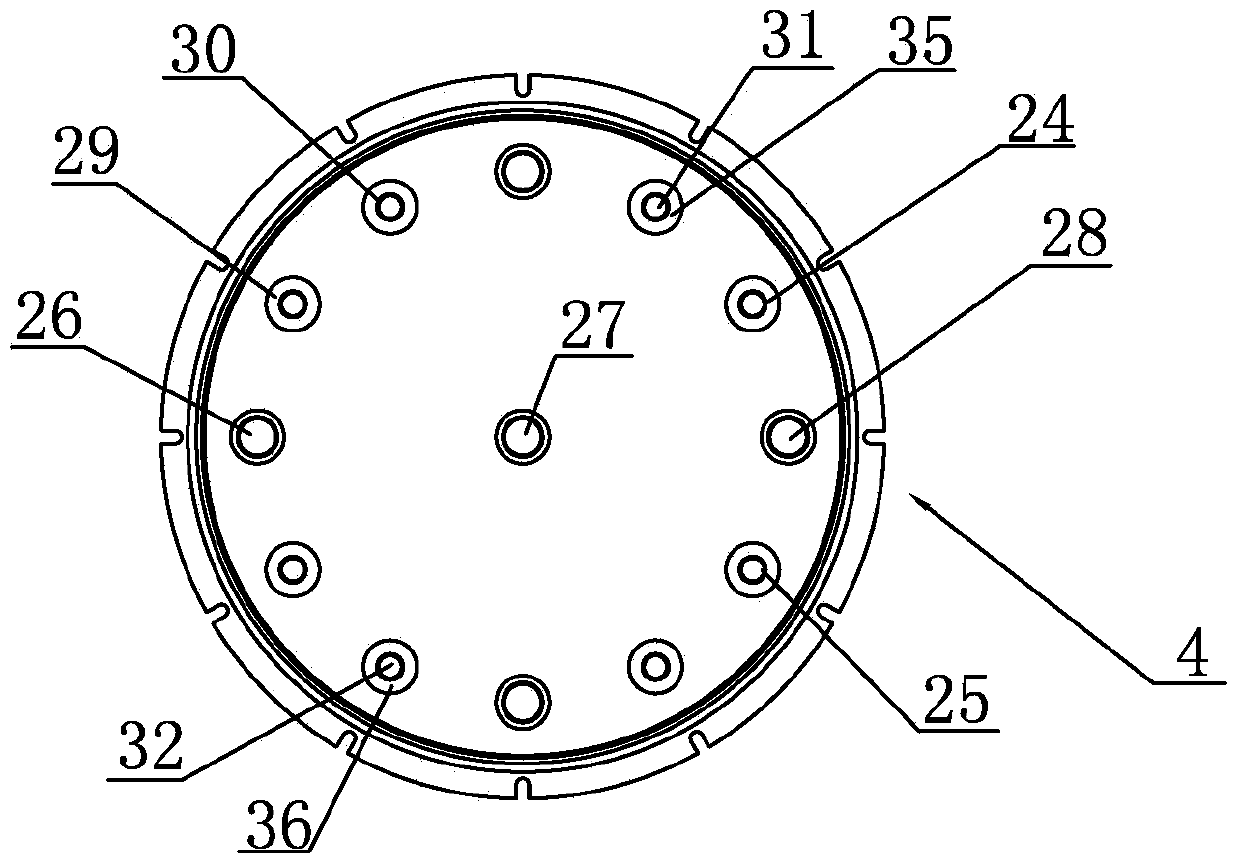

[0038] A pneumatic self-circulation animal cell culture bioreactor, such as figure 1 and figure 2 As shown, it includes a large tank 1, a small tank 2, a magnetic stirring system 3, a heating system and a control system. The upper end of the large tank 1 is provided with a sealing cover 4, and the sealing cover 4 is provided with a liquid inlet 35 and a liquid discharge port 36. Both sides of the large tank 1 are provided with a jacket 5, the jacket 5 is connected to the heating system, the upper part of the large tank 1 is provided with a maximum liquid level sensor 6 of the large tank; the small tank 2 is arranged in the large tank 1 and close to the sealing cover 4, The upper end of the small tank 2 is provided with a sealing head 7 and its lower end is provided with an opening 8 communicating with the large tank 2. The sealing head 7 and the sealing cover 4 are sealed and fixedly connected by the ventilation tube 9, and the upper end of the ventilation tube 9 passes throu...

specific Embodiment 2

[0045] A method for using a pneumatic self-circulation animal cell culture bioreactor, such as figure 1 As shown, it specifically includes the following steps:

[0046] (1) Place the cell carrier in the cavity 13 of the small tank 2 in advance, sterilize the small tank 2 and place it in the large tank 1, and seal and fix the sealing cover 4 of the large tank 1 and the head 7 of the small tank 2 Connect, then the sealing cover 4 is sealed with the large tank 1;

[0047] (2) Mix the cell suspension into the cell culture medium in a certain proportion, send it into the large tank 1 until it touches the high liquid level sensor 6 of the large tank, turn on the magnetic stirring system 3 and mix the cell culture medium in the large tank 1, At the same time, set the parameter values of dissolved oxygen, pH value, temperature, liquid level height, liquid inlet volume and liquid discharge volume through the control system, and then enter the cell culture stage (when setting, the sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com