High-strength multilayer-film photoelectric glass and preparation method thereof

A technology of photoelectric glass and multi-layer film, applied in photovoltaic power generation, coating, circuit and other directions, can solve problems affecting product performance and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

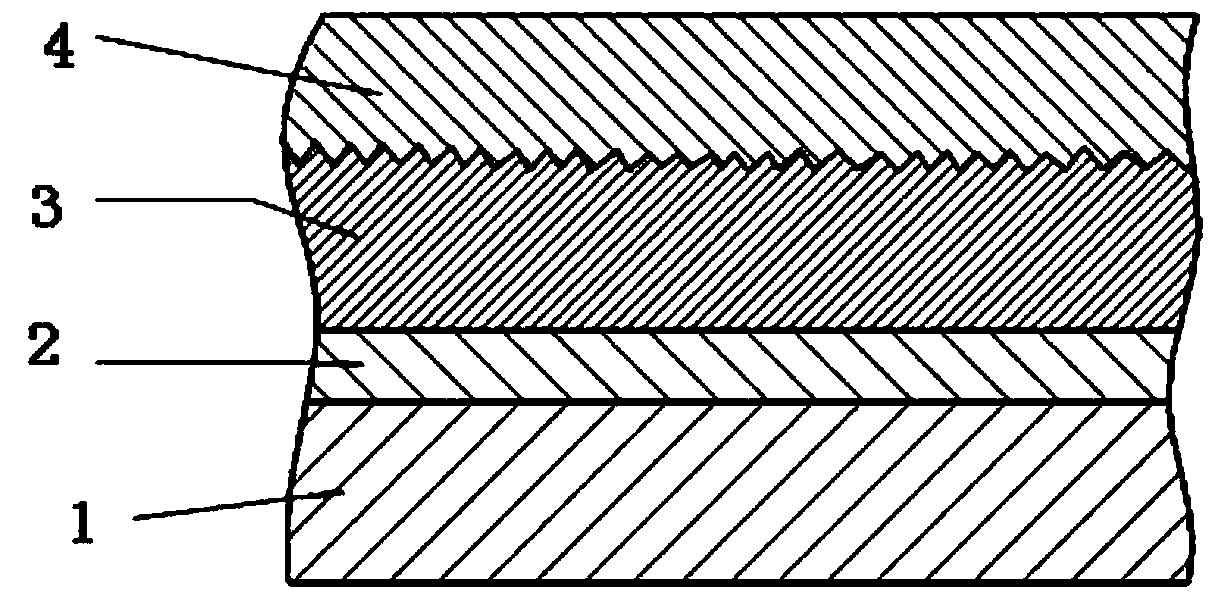

[0025] Example. A high-strength multi-layer photoelectric glass comprises a glass substrate 1 on which a silicon dioxide layer 2 , an aluminum oxide thin film layer 3 and an AZO thin film layer 4 are sequentially arranged. The silicon dioxide layer 2 is a high-purity silicon dioxide layer.

[0026] To realize the preparation method of the aforementioned high-strength multilayer film-based photoelectric glass, proceed as follows:

[0027] ① Pre-clean the glass substrate;

[0028] ② Repeat step ① 3-4 times, and then dry in a vacuum oven;

[0029] ③Cleaning the glass substrate by ion beam sputtering under vacuum conditions;

[0030] ④ In the environment where argon is used as the working gas, silicon dioxide, aluminum oxide and AZO (collectively referred to as sputtering targets) are ...

PUM

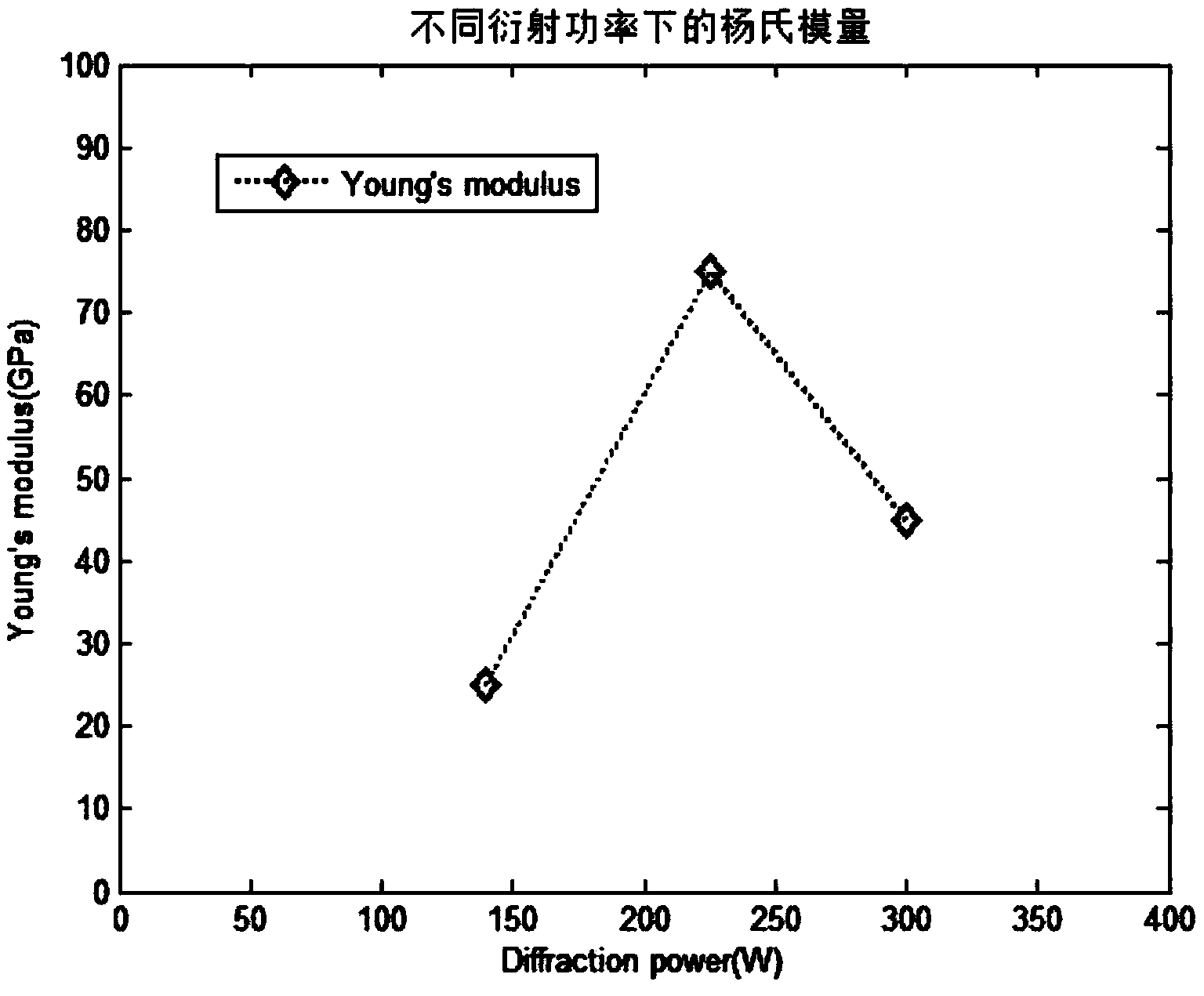

| Property | Measurement | Unit |

|---|---|---|

| Young's modulus | aaaaa | aaaaa |

| Young's modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com