MOCVD reaction room used for growing graphene

A reaction chamber and graphene technology, applied in the field of microelectronics, can solve the problems of poor uniformity of graphene materials, complex procedures, poor temperature uniformity, etc., and achieve the effects of improving crystal quality and effective area, improving preparation efficiency, and improving uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

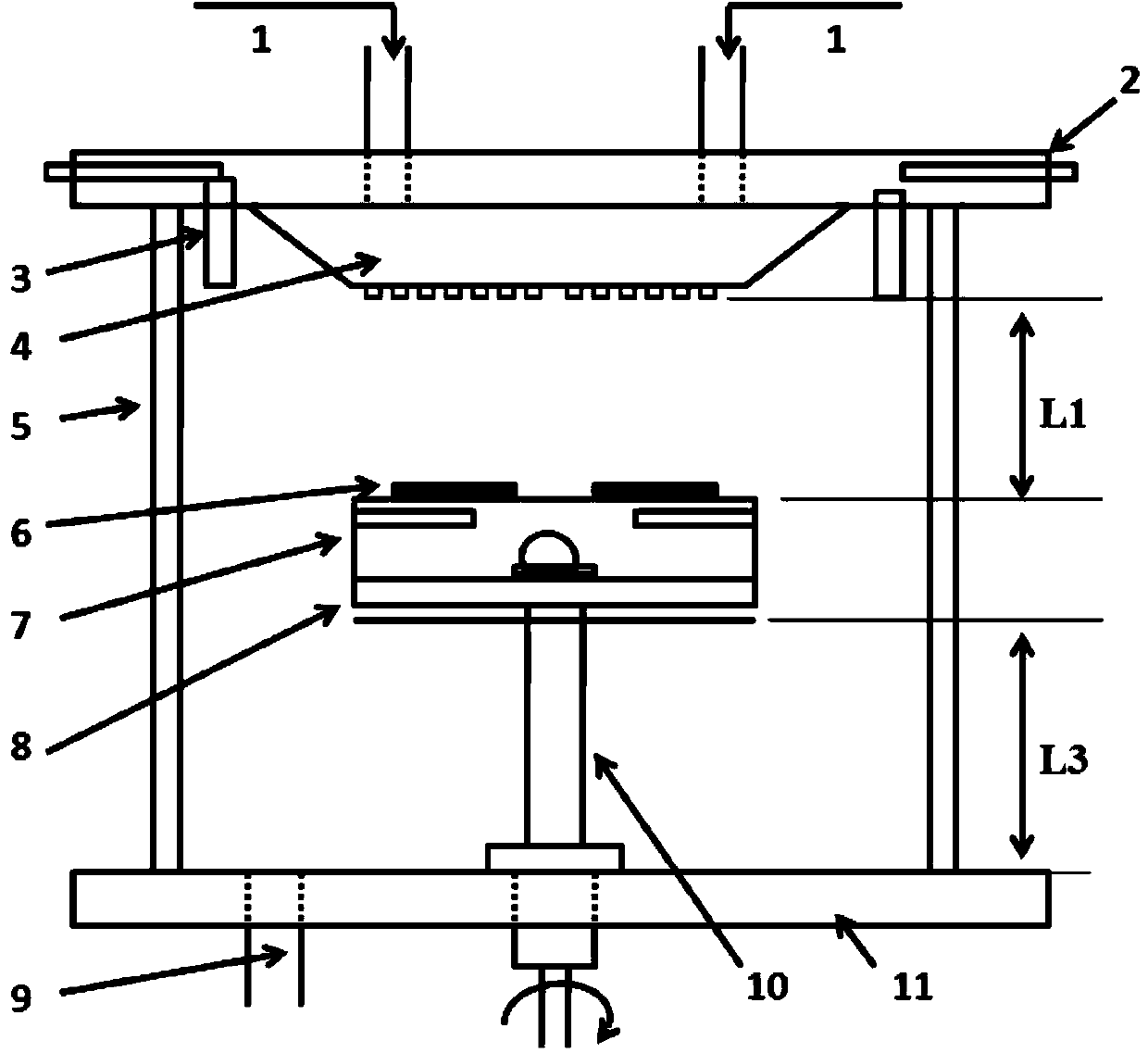

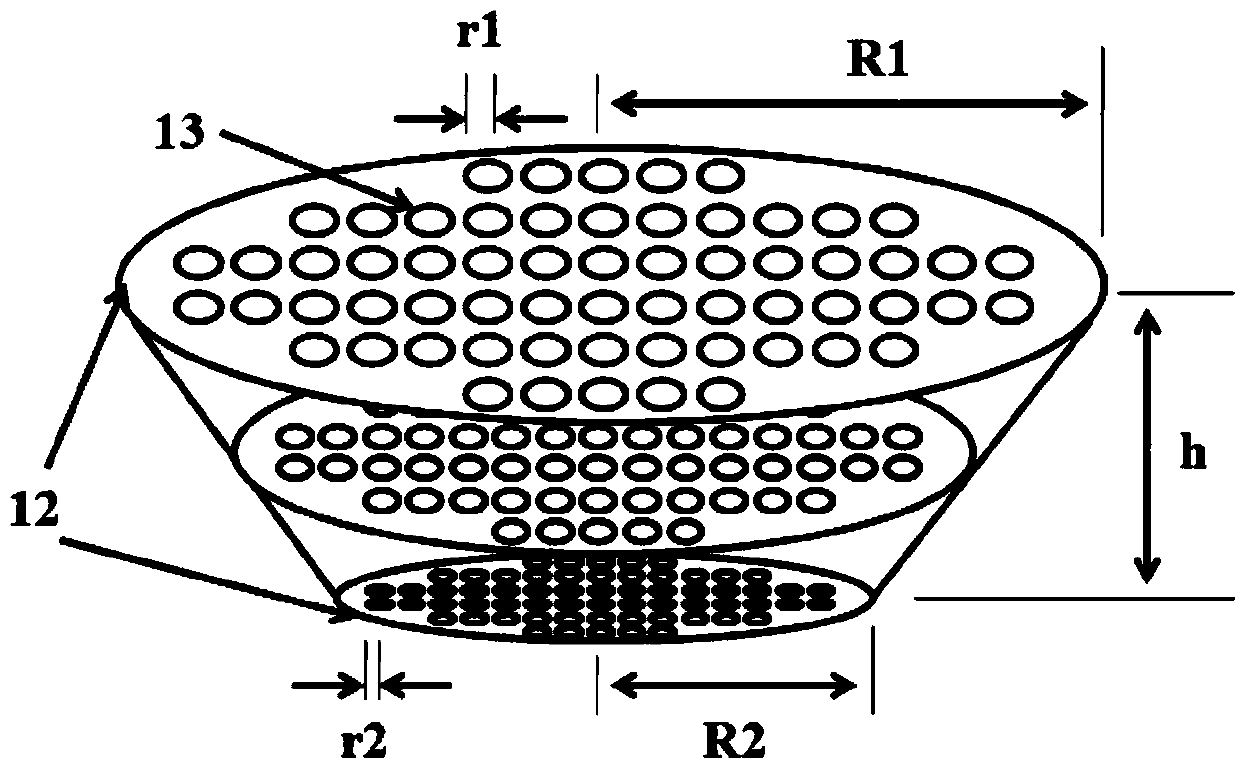

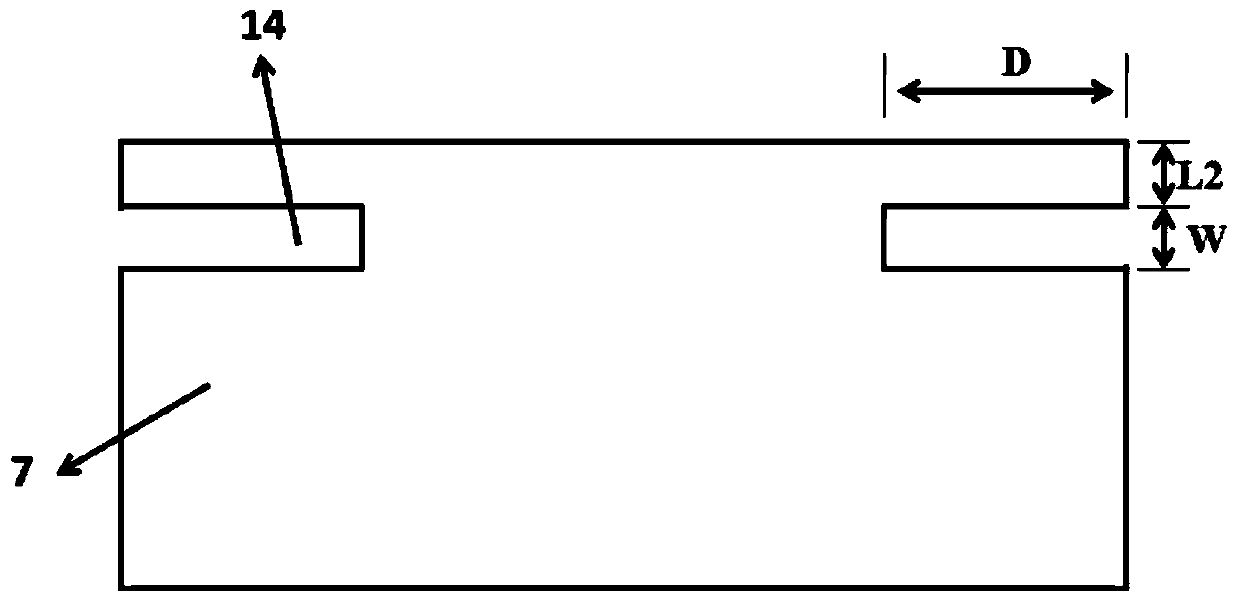

[0033] The radius R1 of the upper surface of the sprinkler 12 is 6 cm, the radius R2 of the lower surface is 3 cm, the height h of the sprinkler 4 is 2 cm, the number of nozzles N is 20, the radius r1 of the top nozzle is 2 mm, and the radius r2 of the bottom nozzle is 1 mm The depth D of the groove 14 is 10mm, the height W is 1mm, the distance L2 between the groove and the base surface is 2mm; the distance L1 between the shower head 4 and the graphite base 7 is 10cm, and the graphite base 7 and the exhaust port 9 The distance L3 is 10cm; the revolution speed of the graphite base 7 is 100r / min, and the rotation speed is 100r / min; the purge gas is Ar.

Embodiment 2

[0035]The radius R1 of the upper surface of the sprinkler 12 is 7cm, the radius R2 of the lower surface is 3.5cm, the height h of the sprinkler 4 is 2.5cm, the number of nozzles N is 30, the radius r1 of the top nozzle is 3mm, and the radius r2 of the bottom nozzle 1.5mm; the depth D of the groove 14 is 15mm, the height W is 2mm, the distance L2 between the groove and the base surface is 4mm; the distance L1 between the shower head 4 and the graphite base 7 is 12cm, the graphite base 7 and the row The distance L3 of the gas port 9 is 12cm; the revolution speed of the graphite base 7 is 200r / min, and the rotation speed is 120r / min; the purge gas is H 2 .

Embodiment 3

[0037] The radius R1 of the upper surface of the sprinkler 12 is 10 cm, the radius R2 of the lower surface is 5 cm, the height h of the sprinkler 4 is 4 cm, the number of nozzles N is 60, the radius r1 of the top nozzle is 5 mm, and the radius r2 of the bottom nozzle is 2.5 mm; the depth D of the groove 14 is 25mm, the height W is 4mm, the distance L2 between the groove and the base surface is 8mm; the distance L1 between the shower head 4 and the graphite base 7 is 15cm, and the graphite base 7 and the exhaust port The distance L3 of 9 is 15cm; the revolution speed of the graphite base 7 is 500r / min, and the rotation speed is 300r / min; the purge gas is N 2 .

[0038] During work, at first the semiconductor insulating substrate 6 is placed on the top of the graphite base 7, then the transition metal organic source is passed into the reaction chamber from the source inlet 1, and the purge gas is passed into the reaction chamber from the purge air flow device, by changing The c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com