Fe3O4-Au magnetic nano composite material, and preparation method and application thereof

A fe3o4-au, magnetic nanotechnology, applied in the preparation of organic compounds, preparation of amino hydroxyl compounds, nanotechnology, etc., can solve the problems affecting the performance of magnetic cores and cumbersome steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

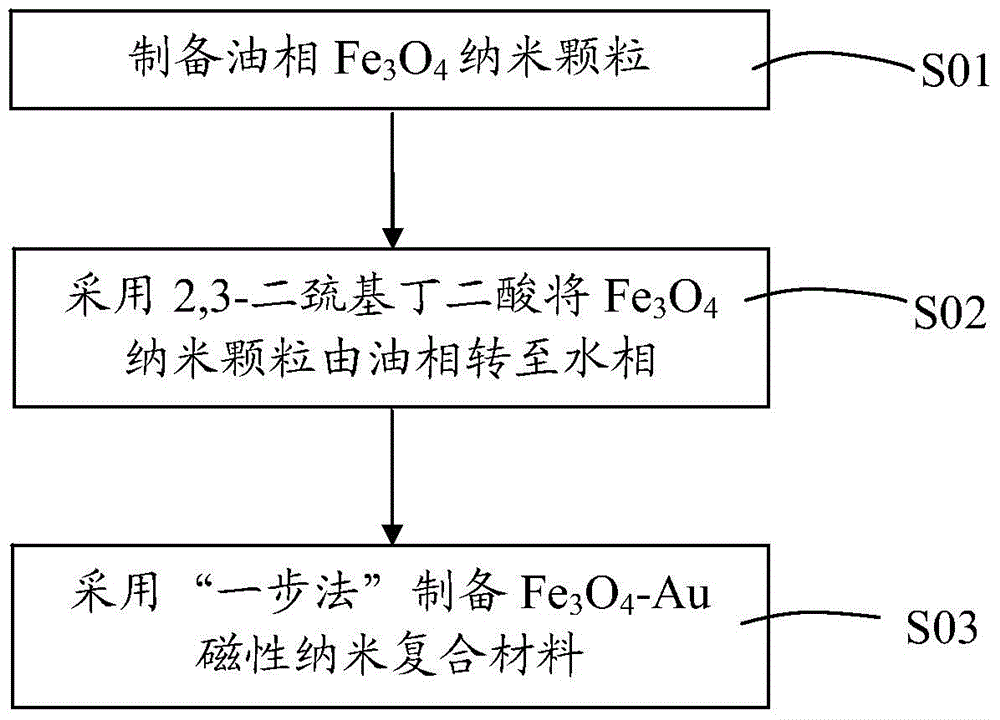

[0021] The embodiment of the present invention provides a kind of Fe 3 o 4 -The preparation method of Au magnetic nanocomposite material, the flow process of its preparation method is as follows figure 1 shown, including the following steps:

[0022] S01. Preparation of Fe in oil phase 3 o 4 nanoparticles;

[0023] S02. Using 2,3-dimercaptosuccinic acid to convert Fe 3 o 4 Nanoparticles are transferred from the oil phase to the water phase: the above oil phase Fe 3 o 4 The nanoparticles were dispersed in an organic solvent, and the organic solution of 2,3-dimercaptosuccinic acid was added to the oil phase Fe 3 o 4 Nanoparticles undergo surface ligand exchange reaction. After the reaction is completed, the product is washed with organic solvent, water and adjusted pH in sequence to obtain the aqueous phase Fe 3 o 4 Dispersions;

[0024] S03. Using "one-step method" to prepare Fe 3 o 4 -Au magnetic nanocomposite: the above aqueous phase Fe 3 o 4 After the disper...

Embodiment 1

[0045] a kind of Fe 3 o 4 -The preparation method of Au magnetic nanocomposite material, comprises the steps:

[0046]S11. Weigh 0.353g of iron acetylacetonate and 1.12g of dodecyl alcohol and dissolve it in 5ml of benzyl ether, and add 2ml of oleic acid and 2ml of oleyl ammonium into it, mix well and vacuumize at room temperature for one hour. Then, the temperature was raised to 200° C. under the condition of argon, and kept at this temperature for 2 hours, and then the temperature was gradually raised to 300° C., and kept at this temperature for 1 hour. After the reaction, cool to room temperature, add a certain amount of ethanol and n-hexane to wash in turn, repeat this step 3 times, and obtain an oil phase Fe with a diameter of about 10nm. 3 o 4 nanoparticles.

[0047] S12. the above-mentioned oil phase Fe 3 o 4 The nanoparticles were dispersed in 8 ml of chloroform to form Fe 3 o 4 Chloroform dispersion, take 1ml Fe 3 o 4 Add an equal volume of acetone to precip...

Embodiment 2

[0050] a kind of Fe 3 o 4 -The preparation method of the Au magnetic nanocomposite material is basically the same as the steps of the above-mentioned embodiment 1, the difference is: in the S21 step of the present embodiment, the organic ether solvent is 5ml of phenyl ether; The temperature should be raised to 265°C for the second time; the oil phase Fe obtained after the reaction 3 o 4 The diameter of nanoparticles is about 6nm.

[0051] That is, the specific operation of S21 is as follows:

[0052] Weigh 0.353g of iron acetylacetonate and 1.12g of dodecyl alcohol and dissolve it in 5ml of phenyl ether, and add 2ml of oleic acid and 2ml of oleyl ammonium to it, mix well and vacuumize at room temperature for one hour. Then, the temperature was raised to 200° C. under the condition of argon, and kept at this temperature for 2 hours, and then the temperature was gradually raised to 265° C., and kept at this temperature for 1 hour. After the reaction, cool to room temperatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com