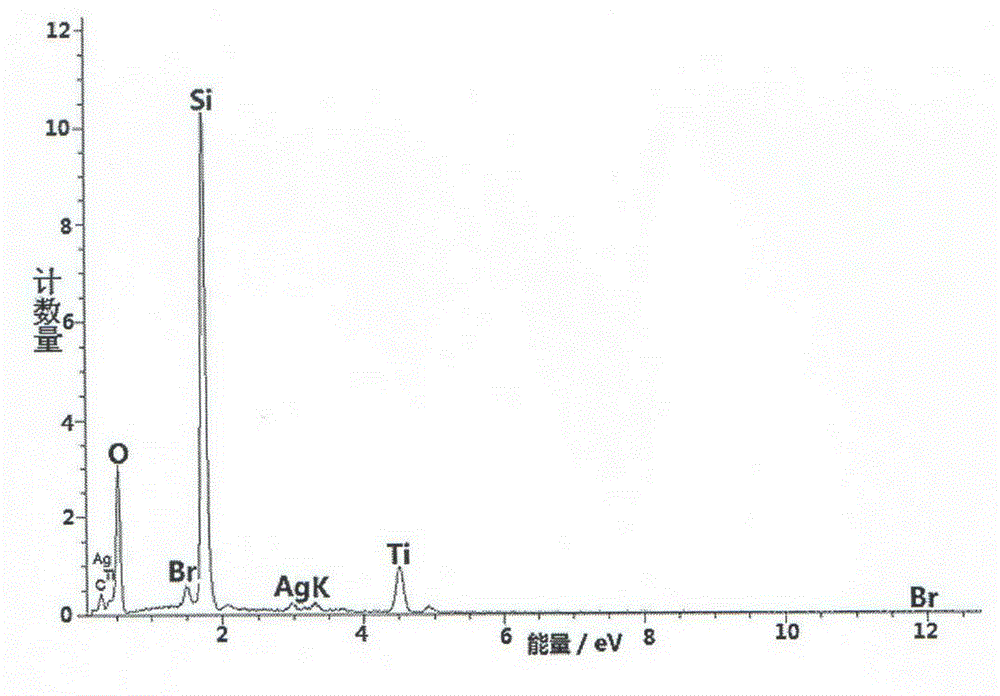

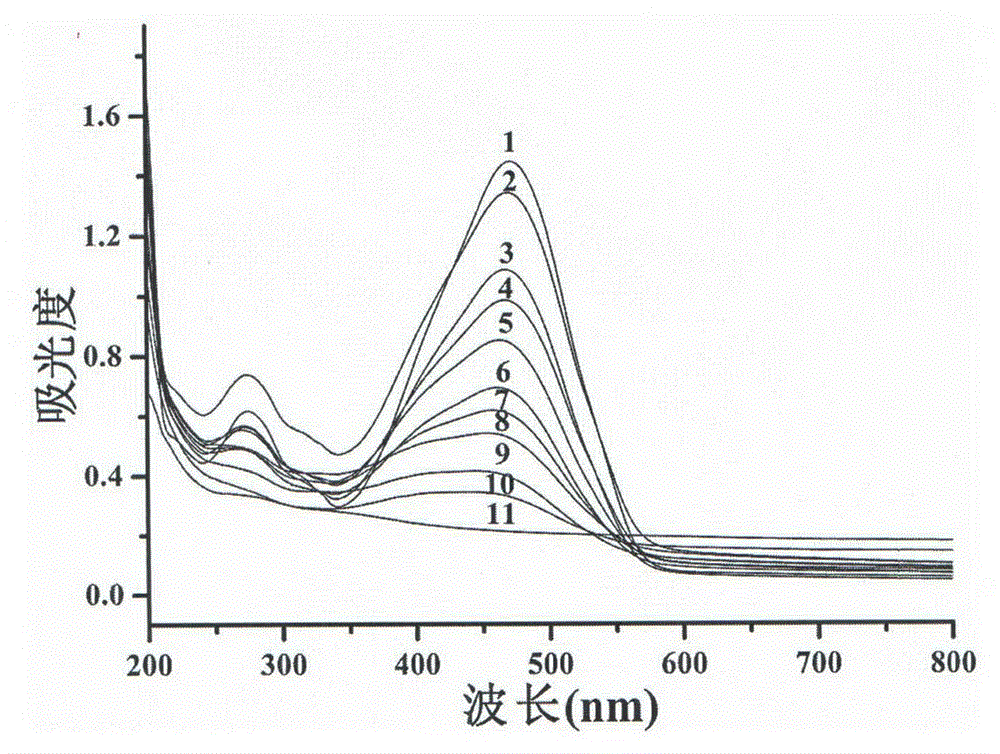

Preparation method of glass fiber loaded silver-silver bromide-titanium oxide composite material

A glass fiber and composite material technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve problems such as difficult recycling and low composite efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] a. Add 0.05M isopropyl titanate to 1M sulfuric acid solution and mix well;

[0022] b. Add 3g of E-glass fiber in short fiber form to the solution obtained in step a, heat up to 110°C, react for 6 hours, adjust the pH value to 7 with concentrated ammonia solution, and after aging for 12 hours, wash and dry to obtain a composite Material;

[0023] c. Add 0.6g polyvinylpyrrolidone to 0.05M ethylene glycol solution containing silver nitrate to obtain a mixed solution, impregnate the composite material obtained in step b into the mixed solution, and then add 0.05M ethylene glycol solution containing potassium bromide After mixing the diol solution evenly, heat it to a temperature of 50°C and keep it warm for 3 hours. After washing the product alternately with deionized water and ethanol, the threaded glass fiber loaded AgBr-TiO can be obtained. 2 Composite photocatalytic materials;

[0024] d. Load the threaded glass fiber with AgBr-TiO 2 The composite material was dispe...

Embodiment 2

[0026] a. Add 0.15M titanium tetrachloride to 1M sulfuric acid solution and mix well;

[0027] b. Add 3 g of C-glass fibers in bundled form to the solution obtained in step a, raise the temperature to 110°C, react for 6 hours, adjust the pH value to 7 with concentrated ammonia solution, and age for 12 hours, wash and dry to obtain a composite Material;

[0028] c. Add 2g of polyvinylpyrrolidone to 0.05M ethylene glycol solution containing silver nitrate to obtain a mixed solution, impregnate the composite material obtained in step b into the mixed solution, and then add 0.05M ethylene glycol containing potassium bromide After mixing the solution evenly, heat it to a temperature of 80°C and keep it warm for 2 hours. After washing the product alternately with deionized water and ethanol, the threaded glass fiber loaded AgBr-TiO can be obtained. 2 Composite photocatalytic materials;

[0029] d. Load the threaded glass fiber with AgBr-TiO 2 The composite material was dispersed ...

Embodiment 3

[0031] a. Add 0.02M ammonium fluotitanate to 1M sulfuric acid solution and mix well;

[0032] b. Add 3g of non-woven fabric AR-glass fiber to the solution obtained in step a, raise the temperature to 110°C, react for 6 hours, adjust the pH value to 7 with concentrated ammonia solution, and after aging for 12 hours, wash and dry to obtain composite materials;

[0033] c. Add 3g of polyvinylpyrrolidone to 0.05M ethylene glycol solution containing silver nitrate to obtain a mixed solution, dip the composite material obtained in step b into the mixed solution, and then add 0.05M ethylene glycol solution containing potassium bromide Alcohol solution, after mixing evenly, heat to a temperature of 150°C and keep it warm for 1 hour. After washing the product alternately with deionized water and ethanol, the threaded glass fiber loaded AgBr-TiO can be obtained. 2 Composite photocatalytic materials;

[0034] d. Load the threaded glass fiber with AgBr-TiO 2 The composite material is d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com