Technology for synthesizing SrTiO3 nano-powder through mechanochemical method

A mechanochemical method, powder technology, applied in chemical instruments and methods, inorganic chemistry, nanotechnology for materials and surface science, etc., can solve the problems of small process batch, inability to obtain fine powder, low degree of automation, etc. , to achieve the effect of good uniformity and consistency, good perovskite structure, and high degree of mechanization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

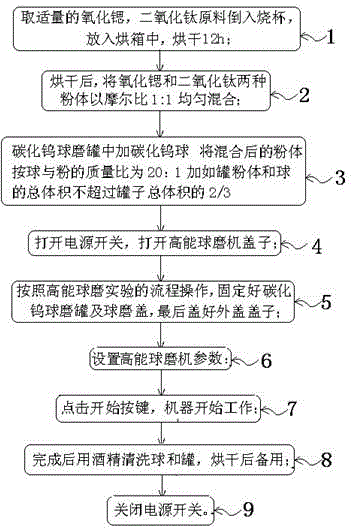

[0022] Such as figure 1 As shown, a mechanochemical method for the synthesis of nano-SrTiO 3 The powder method at least comprises the following steps:

[0023] 1) Take an appropriate amount of strontium oxide and titanium dioxide raw materials and pour them into a beaker, put them in an oven, and dry them for 12 hours;

[0024] 2) After drying, mix the two powders of strontium oxide and titanium dioxide uniformly at a molar ratio of 1:1;

[0025] 3) The number of tungsten carbide balls added to the tungsten carbide ball mill tank is Ф20mm / Ф10mm=1:2, and the mixed powder is added to the tank according to the mass ratio of balls and powders at 20:1; the total amount of powder and balls The volume does not exceed 2 / 3 of the total volume of the jar; After putting the material and balls, add a sealing ring to the jar and cover it;

[0026] 4) Turn on the power switch and open the cover of the high energy ball mill;

[0027] 5) Operate according to the procedure of the high-ener...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com