Preparation method of chitosan modification-polymer composite membrane

A technology of chitosan and sulfonated chitosan, which is applied in the field of fuel cell proton exchange membranes, can solve the problems of low proton conductivity of pure polybenzimidazole and cannot be directly applied to batteries, etc., to overcome low proton conductivity and improve Compatibility, effect of high proton transport channel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

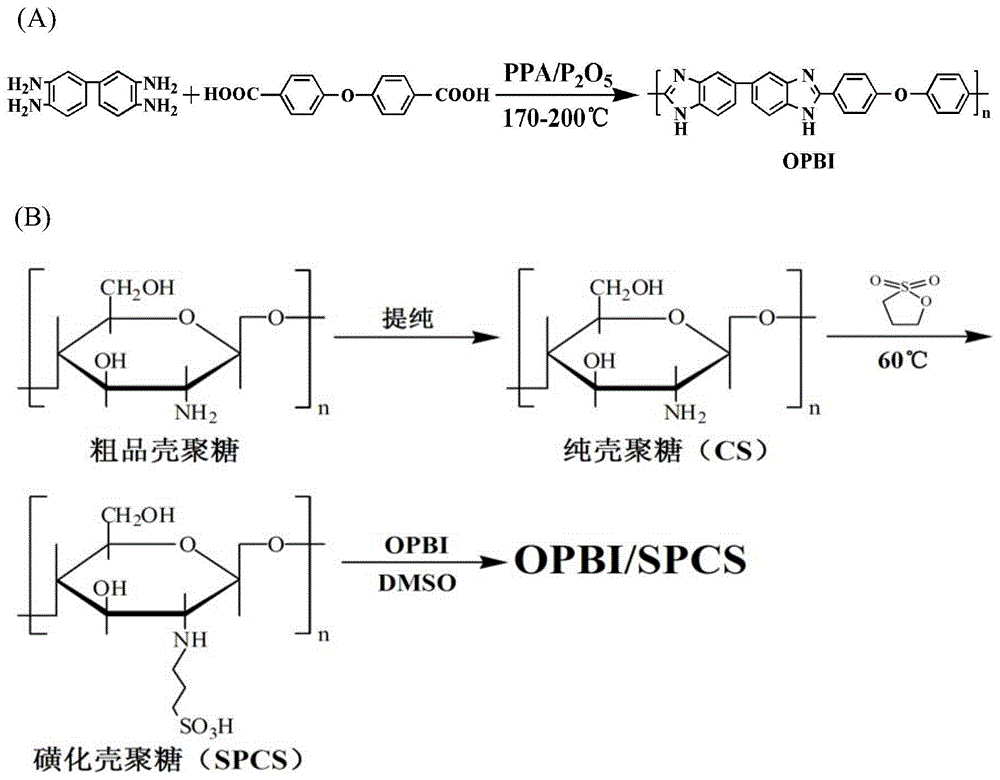

[0021] Embodiment 1: the preparation of polybenzimidazole

[0022] (1) Steps for preparing polybenzimidazole: (see literature: Journal of Membrane Science, 2003, 226, 169-184). The specific preparation steps are: add a certain amount of polyphosphoric acid (PPA, 85%) into a three-necked flask with a mechanical stirring device, and add 3,3',4,4'-biphenyltetramine salt under nitrogen atmosphere acid salt, stir and dissolve at 120°C for 1 hour, remove air bubbles, cool to room temperature, then add dicarboxylic acid (isophthalic acid or 4,4'-dicarboxydiphenyl ether), stir and react at 90°C for 1 hour , stirred at 110°C for 3 hours, at 140°C for 6 hours, at 170°C for 12 hours, and finally at 190°C for 5 hours to end the reaction. Pour the dark brown viscous substance into ice water for precipitation and wash with deionized water and NaHCO 3 The solution was washed repeatedly until neutral, and then dried at 120°C to obtain a brown-yellow polymer.

[0023] The schematic diagram ...

Embodiment 2

[0024] Embodiment 2: Preparation of sulfonated chitosan (SPCS):

[0025] The specific reaction process of the preparation of sulfonated chitosan is as follows: figure 1 As shown in (B), it is divided into 2 steps:

[0026] Purification of chitosan (CS): First, measure 100 mL of distilled water and pour it into a 250 mL beaker, add 0.54 mL of concentrated sulfuric acid, and stir to obtain a sulfuric acid solution with a concentration of 0.1 mol / L. Then add 1g of chitosan to 0.1mol / L sulfuric acid solution, heat and stir to dissolve the crude chitosan, filter while it is hot to remove insoluble impurities, add 0.1mol / L sodium hydroxide solution to the filtrate medium (chitosan is alkaline, therefore, add sodium hydroxide solution to adjust the pH = 11-12), make chitosan precipitate from the acidic solution, filter with suction to obtain chitosan filter cake, and filter chitosan filter cake Dry overnight at 60°C in an electric blast drying oven to obtain pure chitosan.

[0027...

Embodiment 3

[0028] Embodiment 3: the preparation of the OPBI composite membrane of doping 10wt.% sulfonated chitosan:

[0029] (1) Take 1g of ether-bonded polybenzimidazole (OPBI) and dissolve it in 25ml of dimethyl sulfoxide (DMSO). Proper heating can promote the dissolution, and the system becomes a reddish-brown transparent solution;

[0030] (2) The sulfonated chitosan obtained in Example 2 was dissolved in DMSO, and then ultrasonically dispersed for 30 minutes to make it uniformly dispersed.

[0031] (3) Take the DMSO solution of OPBI obtained in step (1) and the sulfonated chitosan dispersion obtained in step (2) and mix them and disperse evenly by ultrasonic, controlling the mass ratio of OPBI to sulfonated chitosan to be 90: 10. Pour the blend solution into a glass tank with a clean and flat bottom, adjust the thickness of the film by controlling the amount of the blend solution poured into it, and dry it in an oven at 80°C for 48 hours; when immersed in deionized water, the compo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com