Crystalline silica solar cell chip diffusion method

A technology for solar cells and crystalline silicon wafers, applied in the directions of crystal growth, diffusion/doping, chemical instruments and methods, etc., can solve the problem of low-efficiency crystalline silicon solar cells, poor uniformity of surface sheet resistance, poor short-wave response of cells, etc. problem, to achieve the effect of low cost, high conversion efficiency and uniform diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

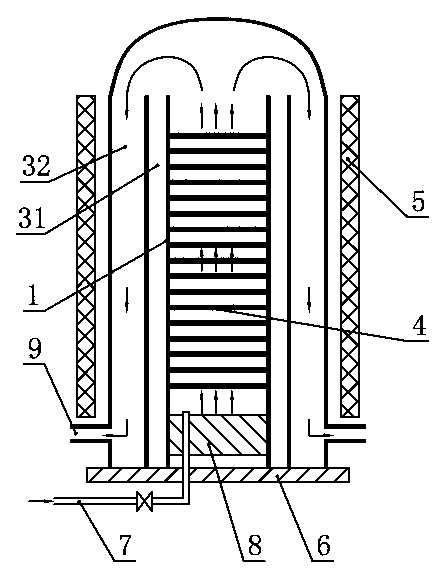

[0020] Such as figure 1 Shown is a schematic structural view of a vertical diffusion furnace used in a crystalline silicon solar cell diffusion method according to the present invention, consisting of an inner furnace chamber 31, an outer furnace chamber 32, and an air inlet 7 at the bottom of the inner furnace chamber 31 , an air extraction port 9 located at the bottom of the outer furnace chamber 32, a furnace door 6, an insulating layer 8, a heater 5 arranged on the outer wall of the furnace body, and a quartz boat 1 for loading crystalline silicon wafers 4. The inner and outer furnace chambers The tops of 31 and 32 communicate with each other. Select a P-type 156×156mm polycrystalline silicon wafer, use hydrofluoric acid or nitric acid to clean the surface oil and texture the crystalline silicon wafer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com