Tungsten trioxide nanosheet and tungsten trioxide nanosheet-doped gas sensor

A technology of gas sensor and tungsten trioxide, which is applied in the field of nanotechnology and new materials, can solve the problems of difficult synthesis, high cost, and obstacles to the preparation of tungsten trioxide nanosheets, and achieve low equipment requirements, fast response capabilities, and excellent preparation process. simple and easy effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

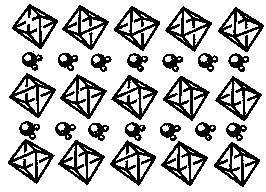

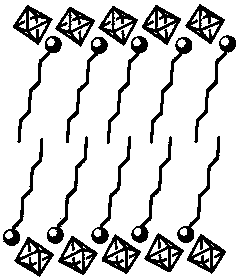

[0022] After thoroughly mixing 20 mL of isopropanolamine and 40 mL of ethanol, add 4 g of tungstic acid (H 2 WO 4 or WO 3 ·H 2 O), figure 1 It is a schematic diagram of the layered structure of tungstic acid. At room temperature, after magnetic stirring for 120 h, the color of tungstic acid gradually changed from light yellow to milky white. After centrifugation, a white solid was obtained. After the obtained sample is washed twice with ethanol, the resulting white powder is dried under low pressure at room temperature and is tungstic acid / organic intercalation compound. figure 2 A schematic diagram of the structure of the compound. Add the white powder to 50 mL of 5 M nitric acid solution, stir magnetically for 12 hours, and centrifuge and wash with ethanol to obtain light yellow tungstic acid (WO 3 2H 2 (0) nanosheets, then place the nanosheets in an alumina crucible, heat to 500°C at a rate of 5°C / min, keep the temperature in air for 2 h, and cool to room temperatur...

example 2

[0024] Disperse 120 mg tungsten trioxide nanosheets in 1 mL of 20mM HAuCl 4 ·3H 2 In the O aqueous solution, the solution is added dropwise to the gas sensor substrate with a heater, heat-treated at 80 °C for 10 min, then the temperature is raised to 400-500 °C, kept at a constant temperature for 0.5-2 h, taken out and cooled to room temperature, that is gas sensor.

example 3

[0026] Put 120 mg of tungsten trioxide nanosheets in 1 mL of 20 mM HAuCl 4 ·3H 2 O aqueous solution, add 2 mg of polyvinylpyrrolidone (Polyvinylpyrrolidone, average molecular weight 40000), after uniform dispersion, the solution is added dropwise to the gas sensor substrate with a heater, heat treatment at 80 °C for 10 min, and then the temperature is raised to 300-500 °C, constant temperature for 0.5-2 h, take it out and cool it to room temperature, it is a gas sensor. In the sensing test of 50 ppm hydrogen sulfide gas, it was found that the traditional solid gas sensor exhibited a phenomenon of "sleeping", that is, when the sensor was exposed to a clean environment, after a period of time (ranging from hours to months) , the first time for the gas T 90 (the time required to reach 90% gas concentration) is significantly longer than the second time, with a difference of about 20 s, such as Figure 4 As shown, the gas sensor using gold-doped tungsten trioxide nanosheets show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com