Strawberry water culture nutrient solution

A technology for hydroponic nutrient solution and strawberry, applied in the field of nutrient solution formulation of hydroponic plants, can solve the problems of strawberry influence, strawberry prone to rotten roots, etc., and achieve the effects of reducing rotten roots, improving disease resistance, and formulating scientifically.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

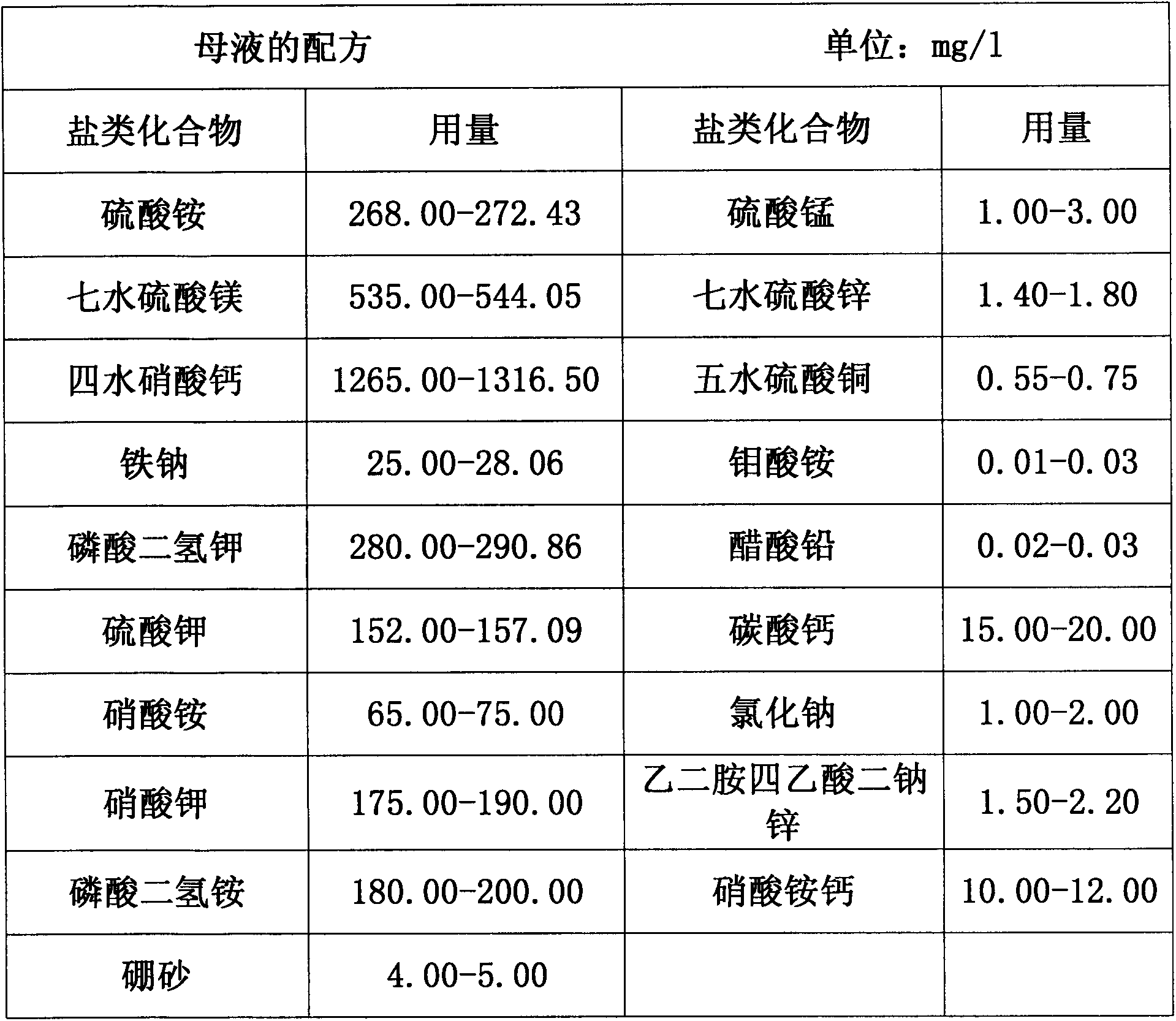

Embodiment 1

[0012] Each 1000ml of the strawberry hydroponic nutrient solution contains 270.22mg of ammonium sulfate, 539.53mg of magnesium sulfate heptahydrate, 1290.75mg of calcium nitrate tetrahydrate, 26.53mg of sodium iron, 285.43mg of potassium dihydrogen phosphate, 154.55mg of potassium sulfate, and 70.00mg of ammonium nitrate , Potassium nitrate 182.50mg, Ammonium dihydrogen phosphate 190.00mg, Borax 4.50mg, Manganese sulfate 2.00mg, Zinc sulfate heptahydrate 1.60mg, Copper sulfate pentahydrate 0.65mg, Ammonium molybdate 0.02mg, Lead acetate 0.03mg, Calcium carbonate 17.50mg , Sodium Chloride 1.50mg, Disodium Zinc EDTA 1.85mg, Calcium Ammonium Nitrate 11.00mg.

Embodiment 2

[0014] Each 1000ml of the strawberry hydroponic nutrient solution contains 268.00mg of ammonium sulfate, 535.00mg of magnesium sulfate heptahydrate, 1265.00mg of calcium nitrate tetrahydrate, 25.00mg of sodium iron, 280.00mg of potassium dihydrogen phosphate, 152.00mg of potassium sulfate, and 65.00mg of ammonium nitrate , Potassium nitrate 175.00mg, Ammonium dihydrogen phosphate 180.00mg, Borax 4.00mg, Manganese sulfate 1.00mg, Zinc sulfate heptahydrate 1.40mg, Copper sulfate pentahydrate 0.55mg, Ammonium molybdate 0.0lmg, Lead acetate 0.02mg, Calcium carbonate 15.00mg , Sodium Chloride 1.00mg, Disodium Zinc EDTA 1.50mg, Calcium Ammonium Nitrate 10.00mg.

Embodiment 3

[0016] Each 1000ml of the strawberry hydroponic nutrient solution contains 272.43mg of ammonium sulfate, 544.05mg of magnesium sulfate heptahydrate, 1316.50mg of calcium nitrate tetrahydrate, 28.06mg of sodium iron, 290.86mg of potassium dihydrogen phosphate, 157.09mg of potassium sulfate, and 75.00mg of ammonium nitrate , Potassium nitrate 190.00mg, Ammonium dihydrogen phosphate 200.00mg, Borax 5.00mg, Manganese sulfate 3.00mg, Zinc sulfate heptahydrate 1.80mg, Copper sulfate pentahydrate 0.75mg, Ammonium molybdate 0.03mg, Lead acetate 0.03mg, Calcium carbonate 20.00mg , Sodium Chloride 2.00mg, Disodium Zinc EDTA 2.20mg, Calcium Ammonium Nitrate 12.00mg.

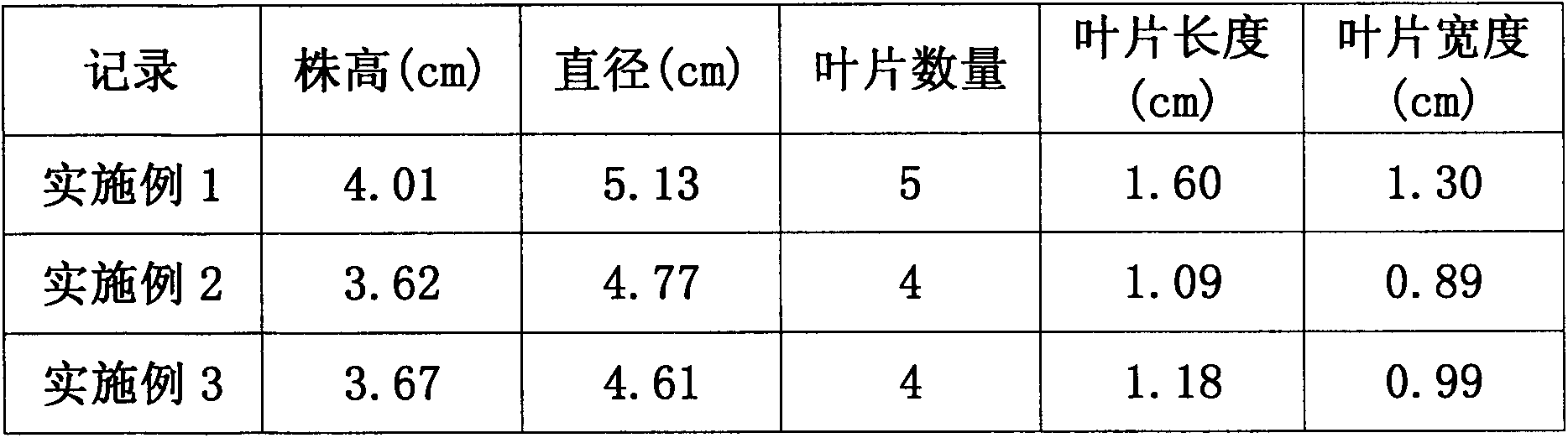

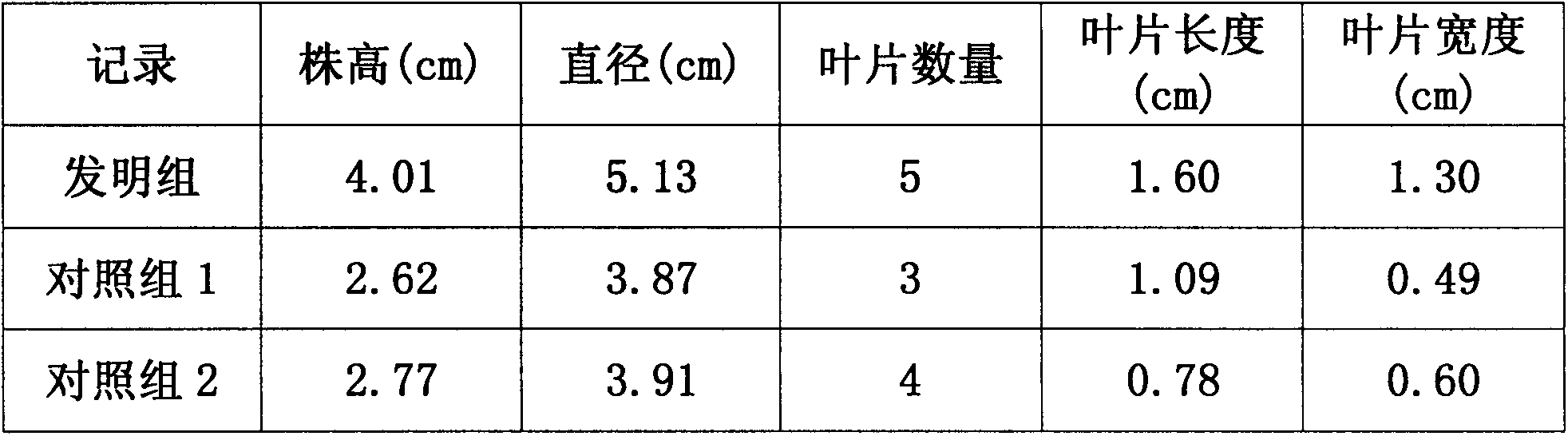

[0017] Described experimental group (embodiment 1, embodiment 2, embodiment 3) selects the same strawberry plant of shape and size, they are placed in identical and suitable environment and cultivate one month, record the growth situation of three groups of experimental plants after one month (Such as figure 2 shown).

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com