Chemical fracturing fluid for hot dry rock

A hot dry rock and fracturing fluid technology, applied in the direction of organic chemistry, chemical instruments and methods, compounds of group 5/15 elements of the periodic table, etc., can solve corrosion, affect thermal reservoir permeability, and prevent thermal reservoir Deep penetration and other issues to achieve the effect of expanding the penetration distance and improving permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The preparation method of hot dry rock chemical fracturing fluid, according to the mass percentage: fluoboric acid (HBF 4 ) 2% to 8%, polyamino polyether group methylene phosphonic acid (PAPEMP) 2.5% to 10%, water 79 to 85.5% and aluminum chloride hexahydrate (AlCl 3 ·6H 2 O) 3% to 10% mixed to make hot dry rock chemical fracturing fluid.

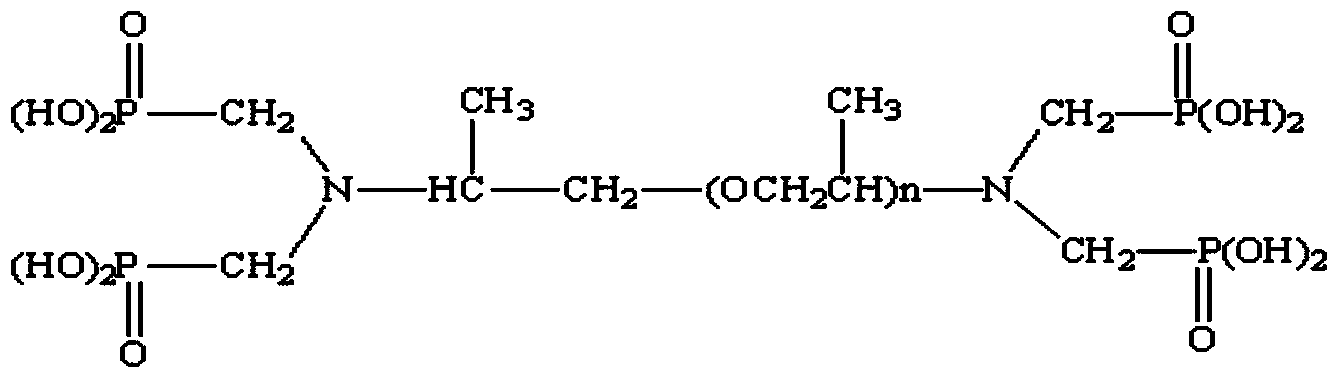

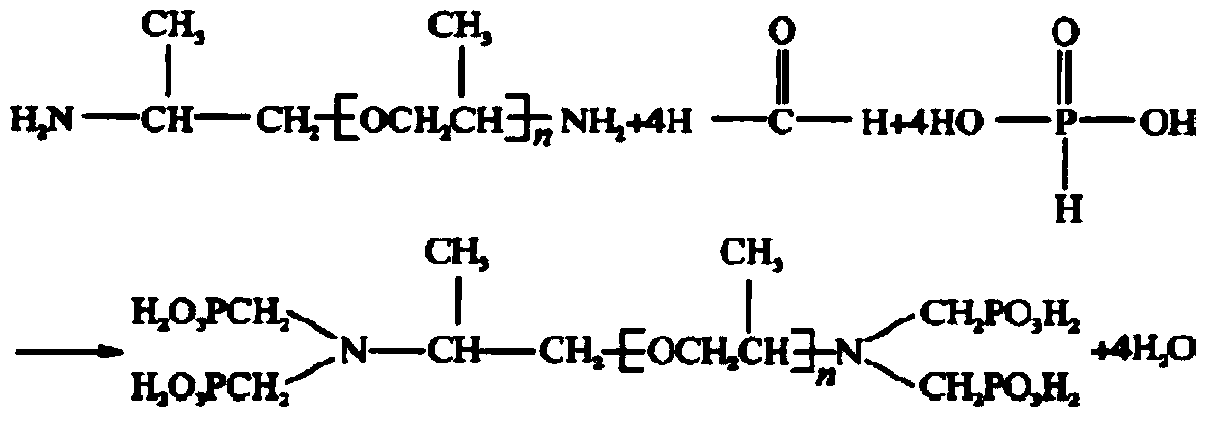

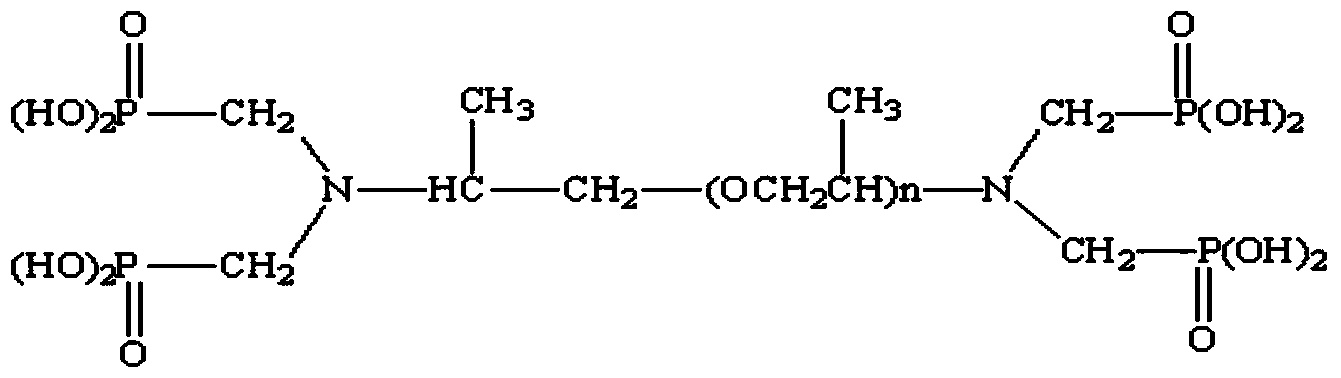

[0032] Synthesis of polyaminopolyether-based methylene phosphonic acid: add 4.62 g of amino-terminated polyether (polymerization degree n=2.6) to a four-necked flask equipped with a reflux condenser, a thermometer, a constant pressure dropping funnel and a magnetic stirrer , phosphorous acid 16.4g, deionized water 7.5ml. Add 5mL of concentrated hydrochloric acid several times, adding 1 to 2ml each time. Heat the oil bath to 105°C, keep stirring, add 3g of formaldehyde solution into the flask during reflux and condensation, ensure that the dropwise addition time is not less than 50min, after the dropwise addition, continue to reflu...

Embodiment 1

[0035] 10g mass fraction is successively HBF of 40% 4 , 12.5g mass fraction is 40% PAPEMP, 72.5g water, 5 grams AlCl 3 ·6H 2 O solids are placed in a vessel and mixed to make hot dry rock chemical fracturing fluid. The dissolution test was carried out on the tuff rock samples of the Yingcheng Formation in the Songliao Basin, a typical EGS thermal reservoir, and the experimental results are as follows:

[0036]

Embodiment 2

[0042] Turn 5g mass fraction into 40%HBF 4 , 12.5g mass fraction is 40% PAPEMP, 77.5g water, 5gAlCl 3 ·6H 2 O solids are placed in a vessel and mixed to make hot dry rock chemical fracturing fluid. The dissolution test was carried out on the tuff rock samples of the Yingcheng Formation in the Songliao Basin, a typical thermal reservoir of EGS. The reaction time was 24 hours, and the dissolution rate of the rock samples was 13.7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com