Internalization into battery cathode lead paste composition

A battery positive electrode and composition technology, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as large sewage, battery capacity decay, and inability to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] In this embodiment, the positive lead paste composition of internalized battery is made of the following raw materials in parts by weight: 1000 parts of lead powder, 1 part of fiber, 0.75 part of phosphoric acid, 1.5 parts of antimony trioxide, 1 part of zinc oxide, and 1 part of aluminum sesquioxide. 0.6 parts of ammonium bicarbonate, 0.4 parts of cerium hydroxide, 1.1 parts of tin oxide, 120 parts of water, and 85 parts of dilute sulfuric acid.

[0027] The density of dilute sulfuric acid is 1.40g / cm 3 ; The apparent density of the lead paste composition is 4.4g / cm 3 .

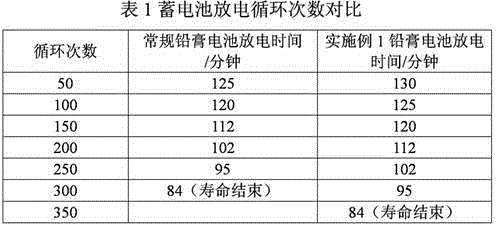

[0028] Table 1 is a comparison of the technical indicators of the electric vehicle lead-acid battery made of the lead paste of this embodiment (taking 6DZM12 battery as an example). The results show that: the conventional electric bicycle battery can be deeply discharged for 300 cycles, while the lead Batteries made of paste can be improved to 350 times.

[0029]

Embodiment 2

[0031] In this embodiment, the positive lead paste composition of the internalized battery is made of the following raw materials in parts by weight: 990 parts of lead powder, 1.5 parts of fiber, 0.5 part of phosphoric acid, 2 parts of antimony trioxide, 0.7 part of zinc oxide, and 1.5 parts of aluminum sesquioxide. 0.5 parts of ammonium bicarbonate, 0.5 parts of cerium hydroxide, 0.7 parts of tin monoxide, 130 parts of water, and 80 parts of dilute sulfuric acid.

[0032] The density of dilute sulfuric acid is 1.45g / cm 3 ; The apparent density of the lead paste composition is 4.2g / cm 3 .

Embodiment 3

[0034] In this embodiment, the positive lead paste composition of the internalized battery is made of the following raw materials in parts by weight: 1010 parts of lead powder, 0.5 part of fiber, 1 part of phosphoric acid, 1 part of antimony trioxide, 1.2 parts of zinc oxide, and 0.5 part of aluminum sesquioxide. 0.8 parts of ammonium bicarbonate, 0.3 parts of cerium hydroxide, 1.5 parts of tin oxide, 110 parts of water, and 90 parts of dilute sulfuric acid.

[0035] The density of dilute sulfuric acid is 1.35g / cm 3 ; The apparent density of the lead paste composition is 4.6g / cm 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com