Hydrolysis resistant thermoplastic polyurethane elastomer and preparation method thereof

A technology of plastic polyurethane and elastomer, applied in the field of hydrolysis-resistant thermoplastic polyurethane elastomer and its preparation, can solve the problems of poor moisture and heat resistance, poor wear resistance, strength and tear properties, and restricted use, and achieves self- Degradation behavior, improving hydrolysis resistance, and the effect of good hydrolysis resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

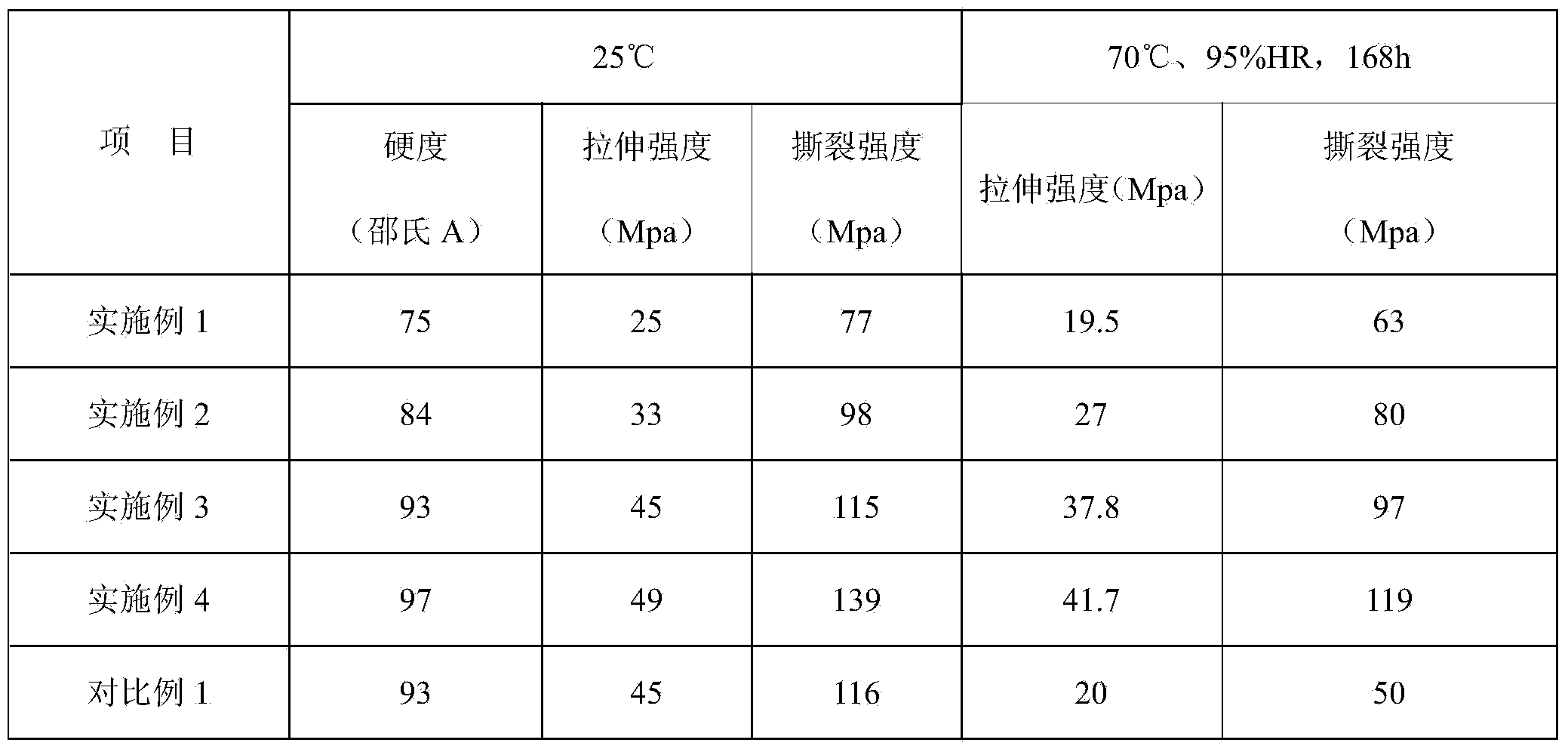

Examples

Embodiment 1

[0024] Synthesis of hydrolysis-resistant thermoplastic polyurethane elastomer: it is made of the following mass fraction raw materials:

[0025] Polyethylene adipate diol (M=2000): 70.4%,

[0026] Diphenylmethane diisocyanate (MDI): 21.5%,

[0027] 1,4-butanediol (BDO): 4.5%,

[0028] Bis(2,6-diisopropylphenyl)carbodiimide (CD-1): 1.0%,

[0029] Polycondensation of tetramethylxylene diisocyanate (PTMXDI): 2%

[0030] Irganox 1010: 0.3%,

[0031] Tinuvin770: 0.3%.

[0032] Preparation method: Add polyester polyol, hydrolysis stabilizer, antioxidant and light stabilizer into the reaction kettle, heat the temperature to 110°C under stirring, dehydrate at -0.1MPa for 2 hours, then lower the temperature to 80°C, add BDO to mix After homogeneity, add molten MDI, isocyanate index r 0 =1.01. Quickly stir and mix evenly, pour it into the mold, press it into a 2mm sheet in a flat vulcanizer, vulcanize at 110°C for 4 hours, then put it in a blast oven for 8 hours at 80°C, and plac...

Embodiment 2

[0034] Synthesis of hydrolysis-resistant thermoplastic polyurethane elastomer: it is made of the following mass fraction raw materials:

[0035] Polybutylene adipate diol (M=2000): 40%,

[0036] Diphenylmethane diisocyanate: 40%,

[0037] 1,2-propanediol: 15%,

[0038] Bis(4-phenoxy-2,6-diisopropylphenyl)carbodiimide: 2.0%,

[0039] PTMXDI: 2.0%,

[0040] Irganox245: 0.5%,

[0041] Tinuvin234: 0.5%.

[0042] Preparation method: Add polyester polyol, hydrolysis stabilizer, antioxidant and light stabilizer into the reaction kettle, heat the temperature to 120°C under stirring, dehydrate at -0.85MPa for 1h, then lower the temperature to 70°C, add 1, After 2-propanediol is mixed evenly, add molten MDI, isocyanate index r 0 =1.03. Quickly stir and mix evenly, pour it into the mold, press it into a 3mm sheet in a flat vulcanizer, vulcanize at 100°C for 3 hours, then put it in a blast oven for 6 hours at 90°C, and place it at room temperature for 7 days to obtain Products wit...

Embodiment 3

[0044] Synthesis of hydrolysis-resistant thermoplastic polyurethane elastomer: it is made of the following mass fraction raw materials:

[0045] Polybutylene adipate diol (M=1500): 75%,

[0046] Diphenylmethane diisocyanate: 20.8%,

[0047] Diethylene glycol: 3%,

[0048] Bis(4-phenoxy-2,6-diisopropylphenyl)carbodiimide: 0.5%,

[0049] PTMXDI: 0.5%,

[0050] Irganox245: 0.1%,

[0051] Tinuvin234: 0.1%.

[0052] Preparation method: Add polyester polyol, hydrolysis stabilizer, antioxidant and light stabilizer into the reaction kettle, heat the temperature to 100°C under stirring, dehydrate at -0.1MPa for 2 hours, then lower the temperature to 90°C, add a shrink After diethylene glycol is mixed evenly, add molten MDI, isocyanate index r 0 =1.01. Quickly stir and mix evenly, pour it into the mold, press it into a 1mm sheet in a flat vulcanizer, vulcanize at 120°C for 2 hours, then put it in a blast oven for 10 hours at 80°C, and place it at room temperature for 7 days to ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com