Edible oil and fat product adopting bonded materials of sterol saponin and phytosterol ester as raw materials

A technology of phytosterol ester and sterol saponin, which is applied in the fields of edible oil/fat, application, food science, etc., can solve the problems of unstable form, method and application research of edible oil production, etc. The effect of health value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

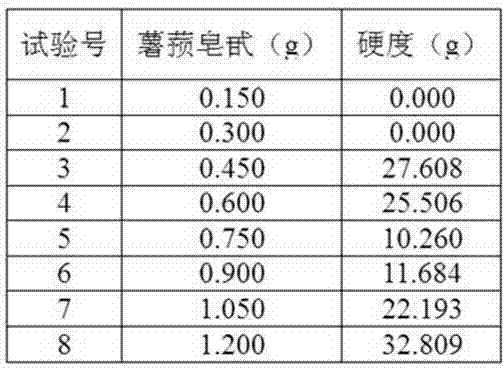

[0029] 1%-8% diosgenin (purity 98%), mixed into oil and stirred at a specific temperature of 90-100°C until a transparent solution is obtained. Add soybean oil and dioscin in a 25ml small beaker, the total mass is 15g, wherein the diosgenin content is variable. The preparation conditions are: stirring until the temperature reaches 100°C; continuous stirring for 15 minutes to obtain a transparent solution; rapid cooling of the solution at a temperature of -40°C, stirring at a speed of 120r / min for 90s; static storage at room temperature solution for 3 days;

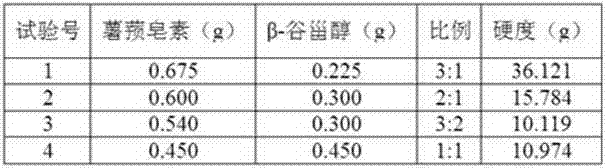

[0030] Table 1 shows the results of measuring the hardness of this solution containing different amounts of diosgenin.

[0031] Table 1

[0032]

[0033] It can be seen from this table that when the content of diosgenin is increased, the hardness decreases first and then increases.

Embodiment 2

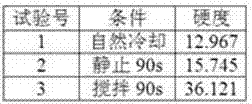

[0035] The solubility of diosgenin and β-sitosterol in soybean oil was better elucidated by a series of dissolution experiments. The other constant conditions in these experiments have been illustrated in Example 1, except that diosgenin was added to the oil and β-sitosterol to achieve a total content of 6%; the mass ratio of diosgenin and β-sitosterol was used as a variable (listed in the table below).

[0036] Table 2 shows the hardness results of the solutions containing different amounts of diosgenin and β-sitosterol. Experiments 1 to 4 are comparative experiments.

[0037] Table 2

[0038]

[0039] This series of experiments clearly demonstrated a synergistic effect of enhancing texture when these two substances were co-dissolved in soybean oil.

Embodiment 3

[0041] In this series of experiments, the storage days of the product after cooling: 1-3-6 days,

[0042] The total content of diosgenin and β-sitosterol is 6%, and other constant conditions have been clarified in Example 1. The texture is measured at room temperature, and the results are shown in the following table:

[0043] table 3

[0044]

[0045] It can be seen from this table that as the storage days increase, the hardness shows a decreasing trend.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com