Compound feed of parabramis pekinensis

A technology of compound feed and bream, which is applied in the field of bream compound feed and fish feed, can solve the problems of complex components, high price, high cost, etc., and achieve the effect of improving growth efficiency, feeding with rich nutrition and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

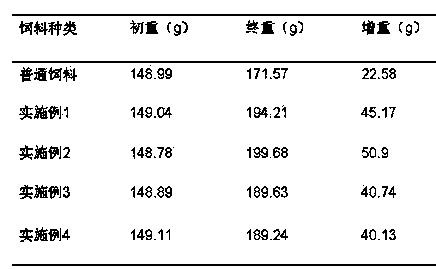

Examples

Embodiment 1

[0013] Combine 15 parts of duckweed, 12 parts of soybean meal, 4 parts of chicken intestine powder, 4 parts of shell powder, 2 parts of earthworm powder, 7 parts of corn stalk powder, and 5 parts of wheat stalk powder, put them in a blender and stir for 30 minutes, take out Then put it into the dryer, control the temperature of the dryer between 50°C and 60°C, and bake for 60 minutes. After taking it out, put it into the puffing machine for puffing, and control the temperature of the puffing machine between 65°C and 75°C , the puffing time is 20 minutes, take it out and let it cool before packing.

Embodiment 2

[0015] Combine 18 parts of duckweed, 15 parts of soybean meal, 5 parts of chicken intestine powder, 3 parts of shell powder, 3 parts of earthworm powder, 8 parts of corn stalk powder, and 6 parts of wheat stalk powder, put them in a blender and stir for 30 minutes, take out Then put it into the dryer, control the temperature of the dryer between 50°C and 60°C, and bake for 60 minutes, take it out and put it into the puffing machine for puffing, and control the temperature of the puffing machine between 65°C and 75°C , the puffing time is 20 minutes, take it out and let it cool before packing.

Embodiment 3

[0017] Combine 10 parts of duckweed, 10 parts of soybean meal, 2 parts of chicken intestine powder, 2 parts of shell powder, 1 part of earthworm powder, 5 parts of corn stalk powder, and 3 parts of wheat stalk powder, put them in a blender and stir for 30 minutes, take out Then put it into the dryer, control the temperature of the dryer between 50°C and 60°C, and bake for 60 minutes, take it out and put it into the puffing machine for puffing, and control the temperature of the puffing machine between 65°C and 75°C , the puffing time is 20 minutes, take it out and let it cool before packing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com