Granular vanadium oxide and production method thereof

A vanadium oxide and production method technology, applied in the direction of vanadium oxide, etc., can solve the problems of uncontrollable average valence state of vanadium in products, large evaporation loss, high energy consumption, etc., reduce impurity content and production energy consumption, and simplify smelting production process, avoiding the effect of the melting process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

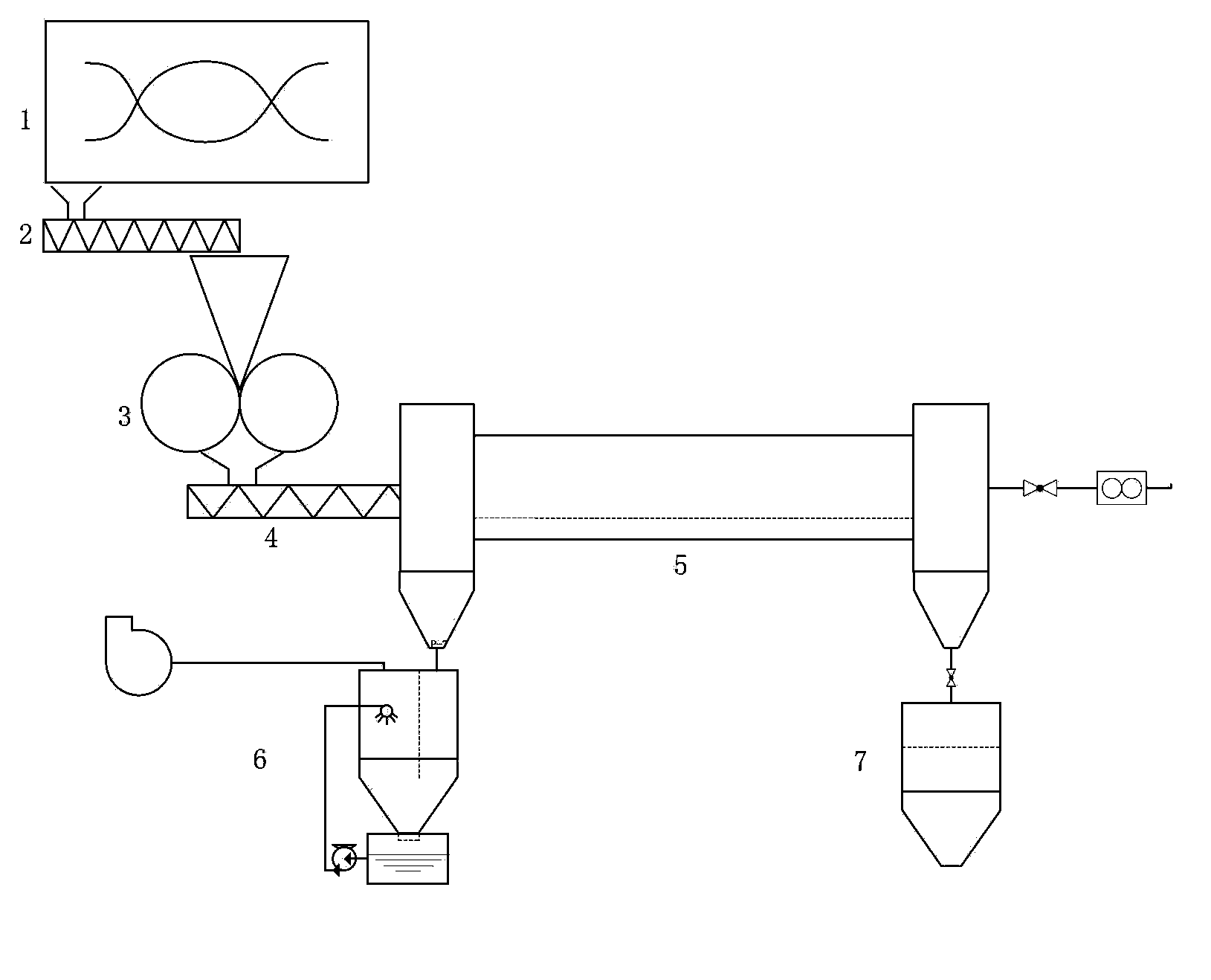

Method used

Image

Examples

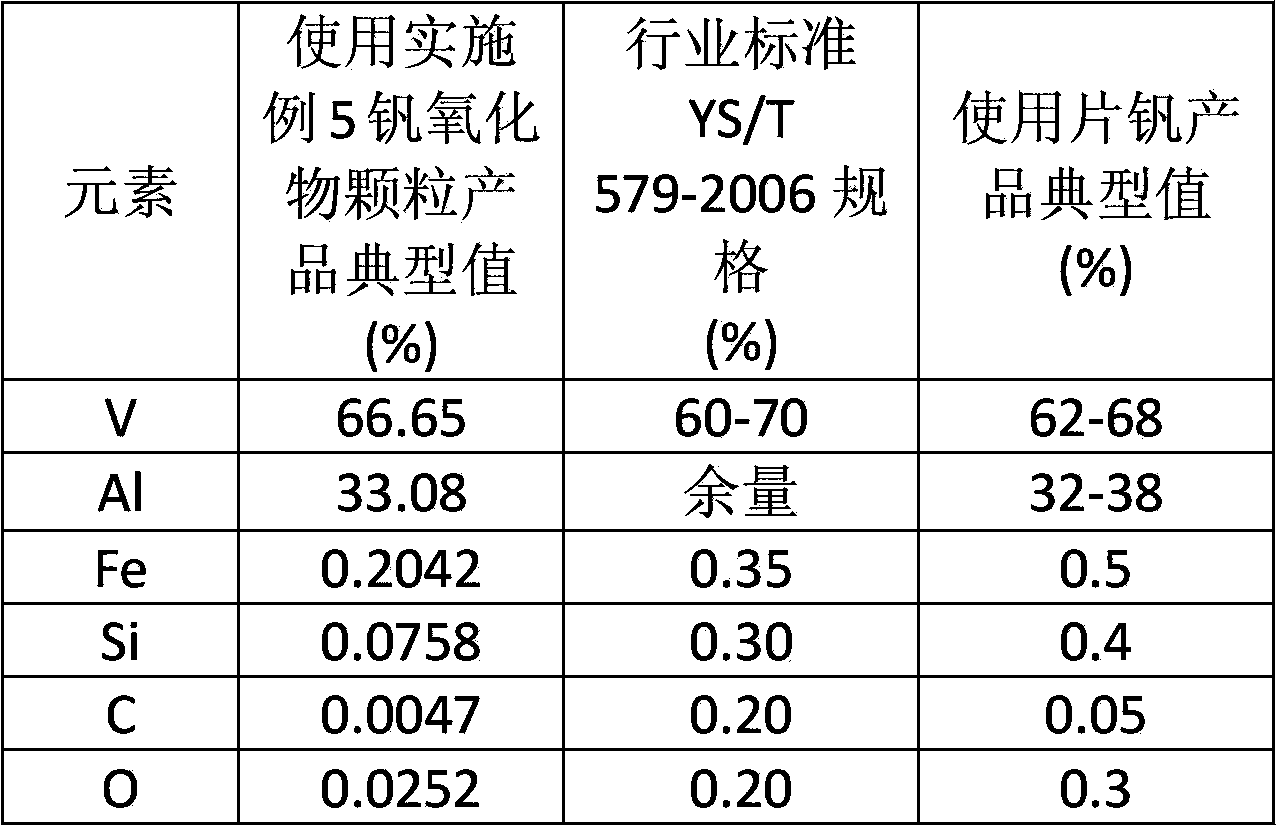

Embodiment 1

[0028] will V 2 o 5 Powder, ammonium polyvanadate (APV), water, dextrin, and graphite powder were sequentially added to the mixer and mixed. The weight ratio of the raw materials was: 500:350:140:10:2, and mixed for 60 minutes. The mixed powder is continuously added to a disc granulator to obtain a granular vanadium oxide precursor. The above-mentioned precursor particles obtained are continuously fed into the rotary kiln by a vibrating feeder. The heating temperature is 600°C. Nitrogen gas is introduced into the furnace. After heating, the material is decomposed and deaminated, and a partial reduction reaction occurs to obtain particles vanadium oxide, the average valence state of vanadium is +4.76, the total impurity content is 0.108%, the particle diameter is 1-3mm, and the average compressive strength is 90N.

Embodiment 2

[0030] Add ammonium polyvanadate (APV), water, and talcum powder into a mixer in sequence for mixing, the weight ratio of the raw materials is 900:100:0.01, and mix for 30 minutes. The mixed powder is continuously added to the double-roll granulator to obtain the granular vanadium oxide precursor, and the above-mentioned precursor particles obtained are continuously fed into the rotary kiln by a screw feeder, and the heating temperature is 700 ℃, nitrogen gas is introduced into the furnace, and the material is decomposed and deaminated by heating, and a partial reduction reaction occurs to obtain granular vanadium oxide. The average valence state of vanadium is +4.50, the total impurity content is 0.13%, the particle diameter is 5-12mm, and the average compressive strength is 110N.

Embodiment 3

[0032] will V 2 o 5 Powder, ammonium metavanadate (AMV), water, dextrin, and talcum powder were sequentially added to the mixer and mixed. The weight ratio of the raw materials was: 500:468:30:5:0.05, and mixed for 30 minutes. The mixed powder is continuously added to a double-roll granulator to obtain a granular vanadium oxide precursor. The above-mentioned precursor particles obtained are continuously fed into the rotary kiln by a screw feeder, the heating temperature is 600°C, nitrogen gas is introduced into the furnace, and the material is decomposed and deaminated by heating to obtain granular vanadium oxide. The average valence state of vanadium is +4.69, the total impurity content is 0.10%, the particle diameter is 3-9mm, and the average compressive strength is 100N.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com