Full-automatic aerobic composting test equipment

A technology of aerobic composting and testing equipment, which is applied in the preparation of organic fertilizers, organic fertilizers, fertilization devices, etc., can solve the problems of inconvenient operation, secondary pollution, and reduced service life of air pumps, and achieve labor-saving, convenient and automatic operation High, the effect of reducing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

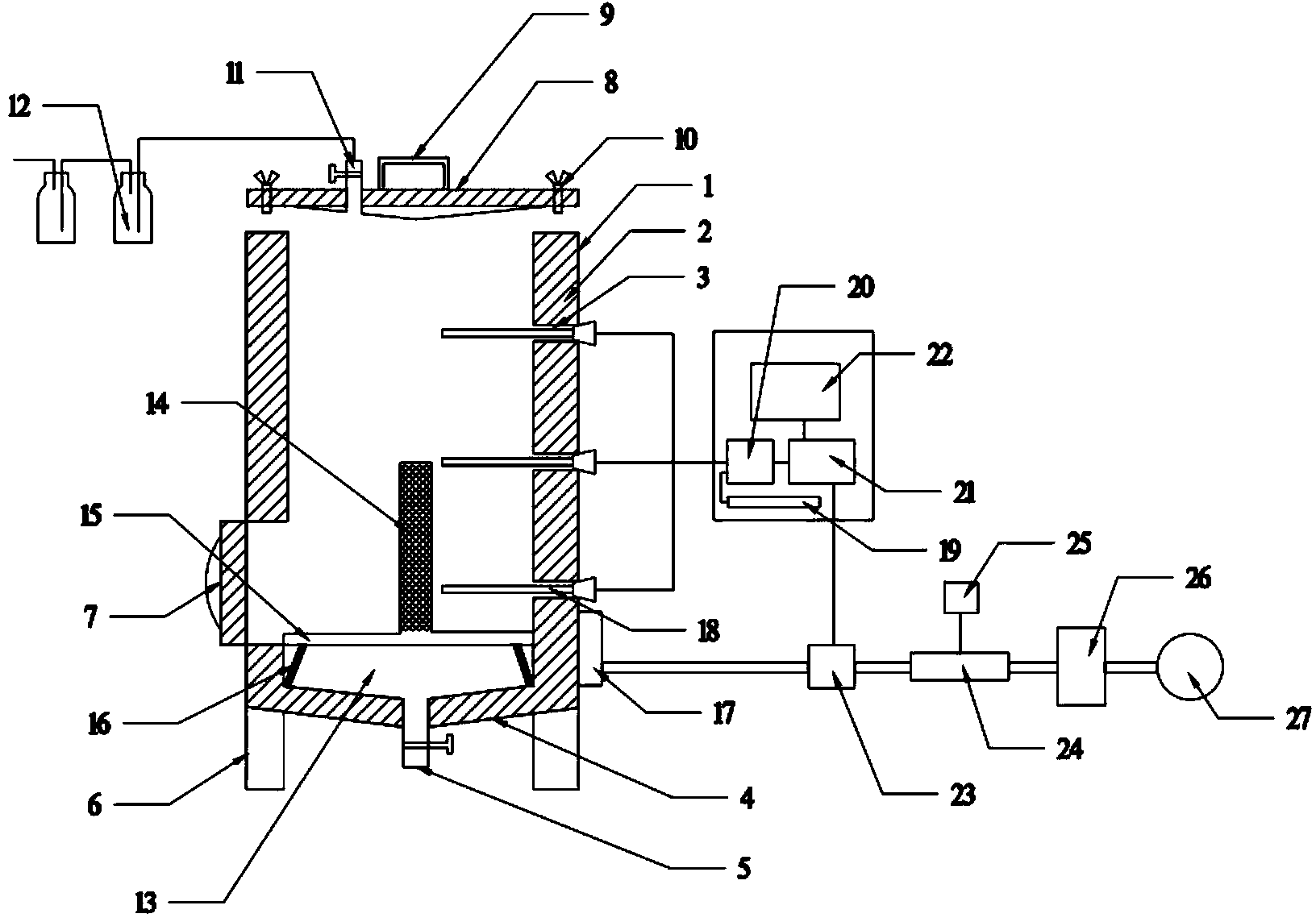

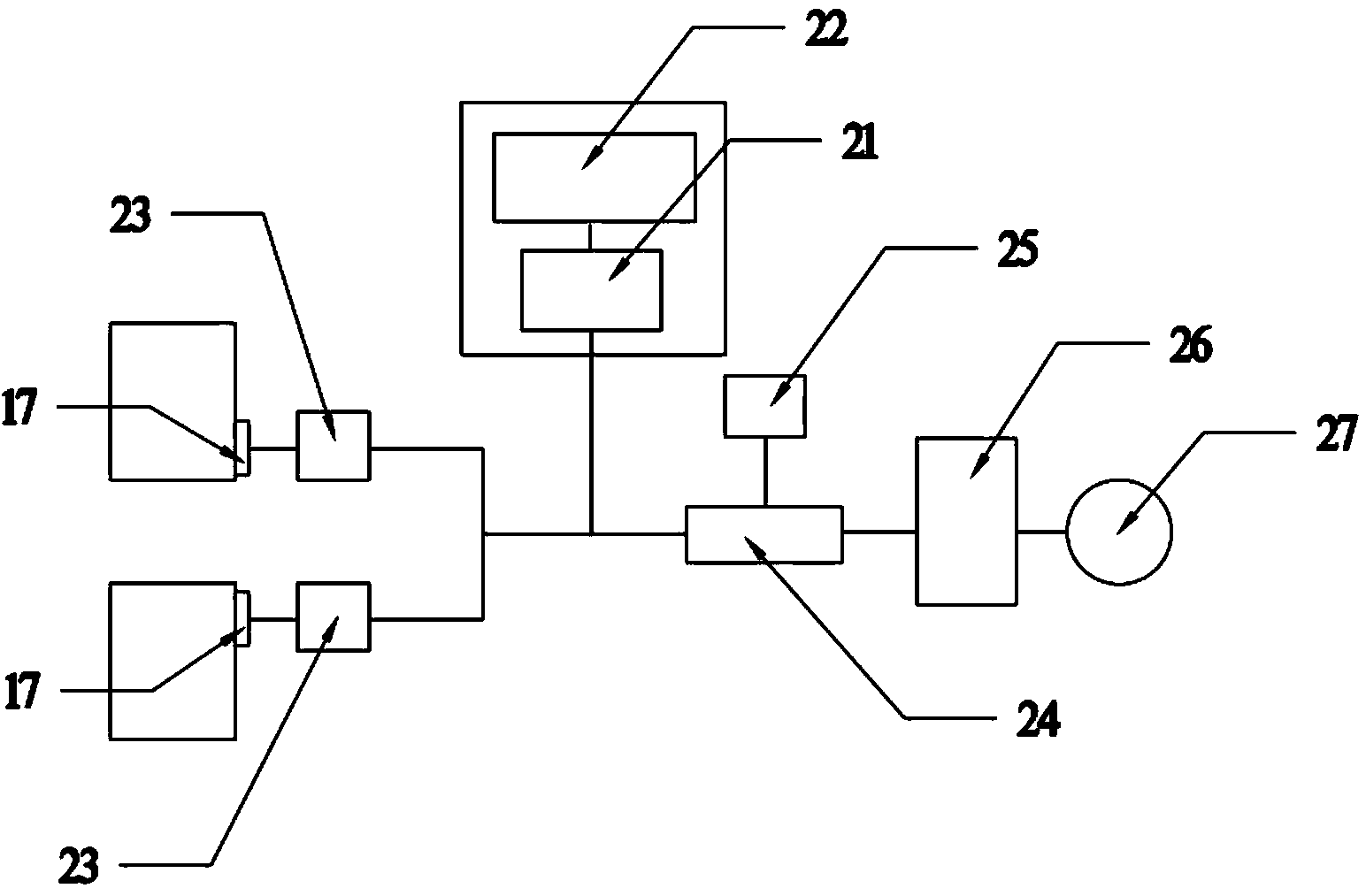

[0032] Such as figure 1 As shown, a fully automatic aerobic composting test equipment mainly includes a fermenter, an intermittent ventilation system, a control system and a sampler.

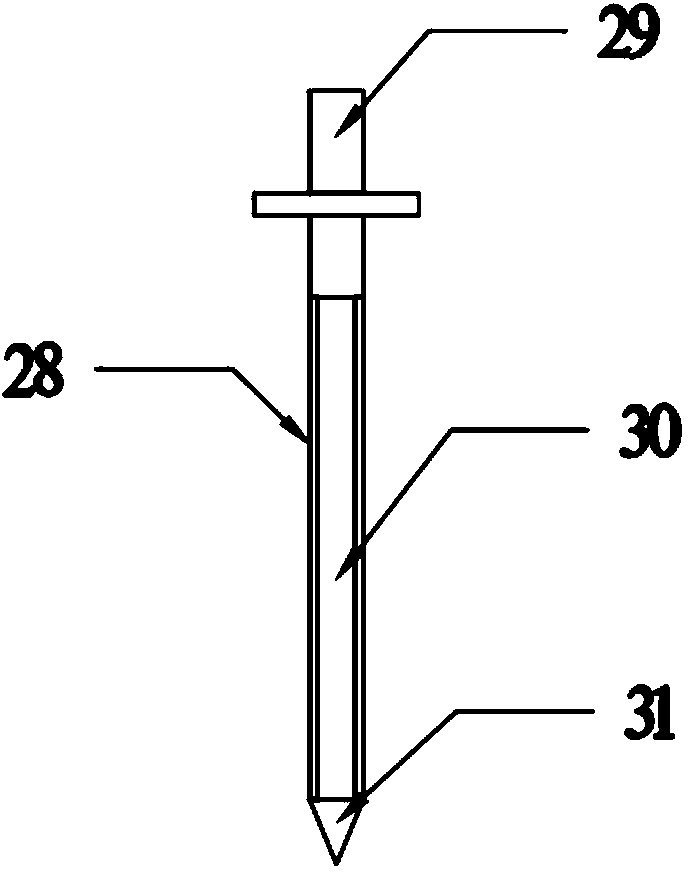

[0033] Wherein the fermenter is supported by the support 6, the fermenter 1 is a cylindrical stainless steel double-layer design, the thickness of the insulation interlayer 2 is greater than or equal to 3cm, and the interior is filled with glass fiber; the bottom of the fermenter 1 is provided with a discharge port 7 to facilitate the composting. Unloading; the side wall of the fermentation tank 1 is provided with upper, middle and lower layers of sampling and temperature ports 3, which can realize the temperature measurement and sample collection of the upper, middle and lower layers of the pile; the tank bottom 4 adopts a slope design, and the lower There is a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com