Method for regulating nutrients in diammonium phosphate product

A diammonium phosphate and product technology, which is applied in the field of product nutrient regulation in the production process of diammonium phosphate, can solve problems such as increasing the production cost of diammonium phosphate, product nutrient deviation, etc., to promote the balance of product nutrient distribution, and promote phosphorus reduction and nitrogen improvement And the balanced distribution of nutrients and nutrients, and the effect of maintaining stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

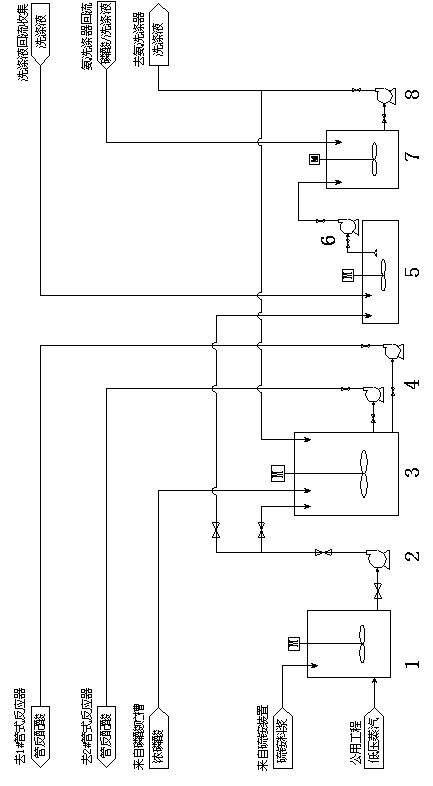

Image

Examples

Embodiment Construction

[0024] Ammonium sulfate slurry from phosphogypsum crystal ammonium sulfate plant, density 1.24~1.28g / cm 3 , with a moisture content of 40% to 50% (dry basis), good water solubility and fluidity. The slurry pump is transported to the ammonium sulfate slurry buffer storage tank of the diammonium phosphate plant. The delivery pipeline is connected with a low-pressure steam purge line, and there is a heating steam pipe and its insulation layer to prevent the ammonium sulfate slurry from cooling and crystallization during the transportation process. , clogging the pipeline.

[0025] The ammonium sulfate slurry from the ammonium sulfate unit is transported to the ammonium sulfate slurry buffer storage tank of the diammonium phosphate unit through the insulated pipeline. The ammonium sulfate buffer storage tank used has a volume of 60m 3 , Keep the slurry reserve level above 60%. Equipped with a stirrer and steam heating and heat preservation device, the outer layer has a he...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com