A kind of method of soaking corn in cornstarch production process

A production process, corn soaking technology, applied in the field of corn deep processing, can solve the problems of SO2 gas health hazards, long soaking time, serious pollution, etc., and achieve the effects of shortening soaking time, reducing energy consumption, and increasing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

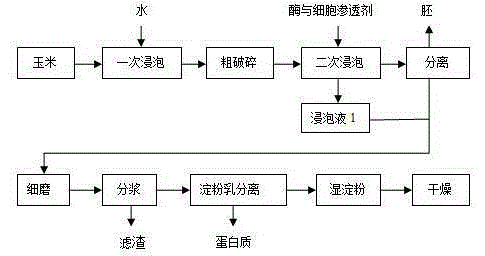

Method used

Image

Examples

Embodiment 1

[0013] Accurately weigh 500g of hard-toothed corn, add water according to the ratio of corn:water=1:1, put it in a constant temperature water bath at 50°C, soak for 3 hours; filter out the soaking water, and use a grinder to crush it into roughly 4-8 pieces, then Add acid protease at 15000U / (100g corn), add cell penetrating agent dioctyl maleate sodium sulfonate at 0.1g / (100mL water), adjust the pH to 3.0 with hydrochloric acid, and place in a water bath shaker at 50°C Shake and soak for 4 hours, take the soaking solution 1 for later use; add appropriate amount of water to the second-soaked corn, use a glass rod continuously to separate the germ from the bottom, and gradually float to the upper layer under the action of buoyancy, separate it with a sieve, and Rinse the germ with water, wash away the attached starch, collect the lotion 1 and the filtrate 1 for later use; mix the corn separated from the germ with the previous reserve liquid, and refine it through a colloid mill, ...

Embodiment 2

[0015] Accurately weigh 500g of dent corn, add water according to the ratio of corn:water=4:5, put it in a constant temperature water bath at 50°C, soak for 3h; Add acid protease at 17800U / (100g corn), add cell penetrating agent dioctyl maleate sodium sulfonate at 0.1g / (100mL water), adjust the pH to 3.0 with hydrochloric acid, and place in a water bath shaker at 50°C Shake and soak for 4 hours, take the soaking solution 1 for later use; add appropriate amount of water to the second-soaked corn, use a glass rod continuously to separate the germ from the bottom, and gradually float to the upper layer under the action of buoyancy, separate it with a sieve, and Rinse the germ with water, wash away the attached starch, collect the lotion 1 and the filtrate 1 for later use; mix the corn separated from the germ with the previous reserve liquid, and refine it through a colloid mill, and absorb the residue in the mill; pass through a 100-mesh sieve, Separating the filter residue to ob...

Embodiment 3

[0017] Accurately weigh 500g of half-dent corn, add water according to the ratio of corn:water=1:2, place it in a constant temperature water bath at 60°C, soak for 3 hours; filter out the soaking water, and use a grinder to crush it into roughly 4-8 pieces, Then add acid protease at 15000U / (100g corn), add cell penetrating agent 2-2-octyl maleate sodium sulfonate at 0.5g / (100mL water), and adjust the pH to 3.0 with hydrochloric acid, and shake in a water bath at 60°C Soak in medium vibration for 4 hours, take the soaking solution 1 for later use; add appropriate amount of water to the second soaked corn, use a glass rod continuously to separate the germ from the bottom, and gradually float to the upper layer under the action of buoyancy, and separate it with a sieve. And rinse the germ with water, wash off the attached starch, collect the lotion 1 and filtrate 1 for later use; mix the corn after the germ separation and the previous standby liquid, and refine it through a colloi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com