Demulsifying agent as well as preparation method and application thereof

A demulsifier, unsaturated technology, applied in the field of demulsifier and its preparation, can solve the problems of large amount of demulsifier, strong specificity, easy to be affected by electrolyte, etc., and achieve the effect of improving the demulsification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

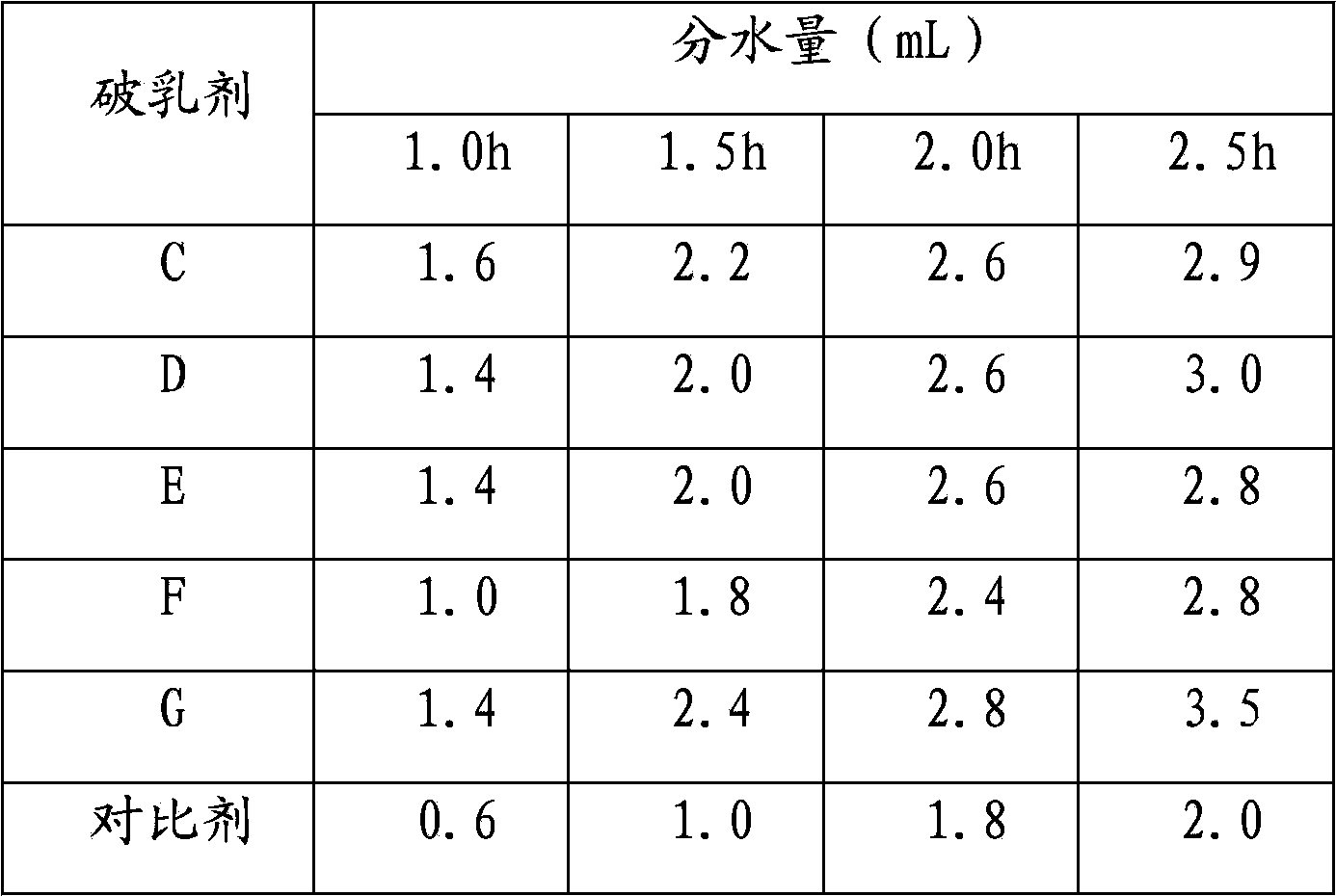

Examples

Embodiment 1

[0040] The synthesis of demulsifier C follows the steps below:

[0041] (1) Add 15g of nonylphenolic resin (relative molecular mass: 1090) and 0.9g of KOH to the autoclave, add dropwise 36.2g of propylene oxide, control the reaction temperature at 130°C, and add 65.8 g ethylene oxide, control temperature 125±5℃, pressure 2.3kg / cm 2 , when the reaction of ethylene oxide is complete, add 72.5g propylene oxide at this temperature, continue the reaction for 0.5h, and wait until the pressure drop of the kettle is 0kg / m 2 , cooling and discharging to obtain block polyether A.

[0042] (2) Take 80g of the above-mentioned block polyether A, add 1.2g of p-toluenesulfonic acid and 0.7g of hydroquinone, stir and raise the temperature. After completion, continue to keep warm at 105-110°C for 1.5h, distill under reduced pressure, remove methanol, and obtain polyether esterification product B.

[0043] (3) In a three-necked flask, add 27g of the above-mentioned polyether esterification p...

Embodiment 2

[0045] The synthesis of demulsifier D follows the following steps:

[0046] Steps (1) and (2) are the same as in Example 1.

[0047] (3) In a three-necked flask, add 27g of the above-mentioned polyether esterification product B, add 0.169g of acrylic acid, 0.469g of AMPS, and 19g of deionized water, and stir to raise the temperature. Dissolve 4.145g of the initiator ammonium persulfate in 13g of deionized water, place it in the dropping funnel, and wait until the temperature of the kettle liquid rises to 85°C, start adding the initiator dropwise, and finish dropping for 0.5h, and continue the reaction for 1.5h after the addition is completed. Cooling and discharging to obtain product D.

Embodiment 3

[0049] The synthesis of demulsifier E follows the following steps:

[0050] Steps (1) and (2) are the same as in Example 1.

[0051] (3) In a three-necked flask, add 27 g of the above-mentioned polyether esterification product B, add 0.169 g of acrylic acid, 0.59 g of AMPS, and 19 g of deionized water, and stir to raise the temperature. Dissolve 2.76g of the initiator ammonium persulfate in 13g of deionized water, put it in the dropping funnel, wait until the temperature of the kettle liquid rises to 85°C, start to add the initiator dropwise, and finish dropping for 0.5h, and continue the reaction for 1.5h after the addition is completed. Cooling and discharging to obtain product E.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com